Product Description

OEM CNC Machining Aluminium Flexible Motor Shaft Coupling

Coupling refers to a device that connects 2 shafts or shafts and rotating parts, rotates together during the transmission of motion and power, and does not disengage under normal conditions. Sometimes it is also used

as a safety device to prevent the connected parts from bearing excessive load, which plays the role of overload protection.

Couplings can be divided into rigid couplings and flexible couplings. Rigid couplings do not have buffering property and the ability to compensate the relative displacement of 2 axes. It is required that the 2 axes be strictly aligned. However, such couplings are simple in structure, low in manufacturing cost, convenient in assembly and disassembly, and maintenance, which can ensure that the 2 axes are relatively neutral, have large transmission torque, and are widely used. Commonly used are flange coupling, sleeve coupling and jacket coupling.

Flexible coupling can also be divided into flexible coupling without elastic element and flexible coupling with elastic element. The former type only has the ability to compensate the relative displacement of 2 axes, but cannot cushion and reduce vibration. Common types include slider coupling, gear coupling, universal coupling and chain coupling; The latter type contains elastic elements. In addition to the ability to compensate the relative displacement

of 2 axes, it also has the functions of buffering and vibration reduction.

Our leading mainly including universal couplings, drum gear couplings, elastic couplings etc.

Main production equipments:

Large lathe, surface grinder, milling machine, spline milling machine, horizontal broaching machine, gear hobbing machine, shaper, slotting machine, bench drilling machine, radial drilling machine, boring machine, band sawing machine, horizontal lathe, end milling machine, crankshaft grinder, CNC milling machine, etc.

Coupling performance

1) Mobility. The movability of the coupling refers to the ability to compensate the relative displacement of 2 rotating components. Factors such as manufacturing and installation errors between connected components, temperature changes during operation and deformation under load all put CZPT requirements for mobility. The movable performance compensates or alleviates the additional load between shafts, bearings, couplings and other components caused by the relative displacement between rotating components.

(2) Buffering. For the occasions where the load is often started or the working load changes, the coupling shall be equipped with elastic elements that play the role of cushioning and vibration reduction to protect the prime mover and the working machine from little or no damage.

(3) Safe, reliable, with sufficient strength and service life.

(4) Simple structure, easy to assemble, disassemble and maintain.

Inspection equipment:

Dynamic balance tester, high-speed intelligent carbon and sulfur analyzer, Blochon optical hardness tester, Leeb hardness tester, magnetic yoke flaw detector etc.

It is widely used in metallurgical steel rolling, wind power, hydropower, mining, engineering machinery, petrochemical, lifting, paper making, rubber, rail transit, shipbuilding and marine engineering and other industries.

How to select the appropriate coupling type

The following items should be considered when selecting the coupling type.

1. The size and nature of the required transmission torque, the requirements for buffering and damping functions, and whether resonance may occur.

2. The relative displacement of the axes of the 2 shafts is caused by manufacturing and assembly errors, shaft load and thermal expansion deformation, and relative movement between components.

3. Permissible overall dimensions and installation methods, and necessary operating space for assembly, adjustment and maintenance. For large couplings, they should be able to be disassembled without axial movement of the shaft.

In addition, the working environment, service life, lubrication, sealing, economy and other conditions should also be considered, and a suitable coupling type should be selected by referring to the characteristics of various couplings.

If you cannot determine the type, you can contact our professional engineer.

Q: Why choose Shengao products?

A: We have our own factory, therefore, we can surely promise the quality of the product and provide

you competitive price.

Q: Do you provide OEM Service?

A: Yes, we provide OEM Service.

Q: Do you provide customized machining parts?

A: Yes. Customers give us drawings and specifications, and we will produce them accordingly.

Q: What is your payment term?

A: We provide kinds of payment terms such as L/C, T/T, Paypal, Escrow, etc.

If there’s anything we can help, please feel free to contact with us.

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated |

|---|

| After-sales Service: | as Specification |

|---|---|

| Warranty: | 6 Months |

| Condition: | New |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | Order Sample machining parts

|

|---|

| Customization: |

Available

| Customized Request |

|---|

What Is a Coupling?

A coupling is a mechanical device that links two shafts together and transmits power. Its purpose is to join rotating equipment while permitting a small amount of misalignment or end movement. Couplings come in a variety of different types and are used in a variety of applications. They can be used in hydraulics, pneumatics, and many other industries.

Types

Coupling is a term used to describe a relationship between different modules. When a module depends on another, it can have different types of coupling. Common coupling occurs when modules share certain overall constraints. When this type of coupling occurs, any changes to the common constraint will also affect the other modules. Common coupling has its advantages and disadvantages. It is difficult to maintain and provides less control over the modules than other types of coupling.

There are many types of coupling, including meshing tooth couplings, pin and bush couplings, and spline couplings. It is important to choose the right coupling type for your specific application to get maximum uptime and long-term reliability. Listed below are the differences between these coupling types.

Rigid couplings have no flexibility, and require good alignment of the shafts and support bearings. They are often used in applications where high torque is required, such as in push-pull machines. These couplings are also useful in applications where the shafts are firmly attached to one another.

Another type of coupling is the split muff coupling. This type is made of cast iron and has two threaded holes. The coupling halves are attached with bolts or studs.

Applications

The coupling function is an incredibly versatile mathematical tool that can be used in many different scientific domains. These applications range from physics and mathematics to biology, chemistry, cardio-respiratory physiology, climate science, and electrical engineering. The coupling function can also help to predict the transition from one state to another, as well as describing the functional contributions of subsystems in the system. In some cases, it can even be used to reveal the mechanisms that underlie the functionality of interactions.

The coupling selection process begins with considering the intended use of the coupling. The application parameters must be determined, as well as the operating conditions. For example, if the coupling is required to be used for power transmission, the design engineer should consider how easily the coupling can be installed and serviced. This step is vital because improper installation can result in a more severe misalignment than is specified. Additionally, the coupling must be inspected regularly to ensure that the design parameters remain consistent and that no detrimental factors develop.

Choosing the right coupling for your application is an important process, but it need not be difficult. To find the right coupling, you must consider the type of machine and environment, as well as the torque, rpm, and inertia of the system. By answering these questions, you will be able to select the best coupling for your specific application.

Problems

A coupling is a device that connects two rotating shafts to transfer torque and rotary motion. To achieve optimal performance, a coupling must be designed for the application requirements it serves. These requirements include service, environmental, and use parameters. Otherwise, it can prematurely fail, causing inconvenience and financial loss.

In order to prevent premature failure, couplings should be properly installed and maintained. A good practice is to refer to the specifications provided by the manufacturer. Moreover, it is important to perform periodic tests to evaluate the effectiveness of the coupling. The testing of couplings should be performed by qualified personnel.

editor by CX 2023-07-07

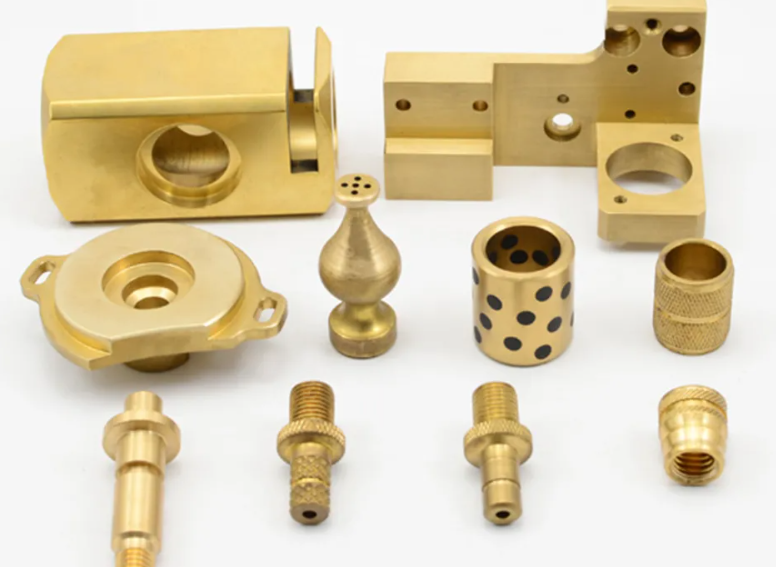

China manufacturer & factory supplier for China in Lusaka Zambia manufacturer for High precision customized cnc machining parts aluminum cnc turning parts With high quality best price & service

industrial factors which includes roller chains. Roller chains are accessible in common, nickel plated & stainless metal resources in pitch dia. ranging from 1/4 in. to 3 in. Varieties consist of leaf chains in lacing configurations ranging from 2 x 2 to 8 x 8. Leaf chains are available in pitch sizes ranging from 1/2 in. to 2 in., pin dia. ranging from .156 in. to .687 in. & tensile strengths ranging from 4,000 lbs. to 156,000 lbs. Purposes include agricultural, conveyors, drilling, electronics assembly, food processing, fork raise vehicles, hoists, packaging & textile machinery.Our AdvantagesProducts Huge volume in Stock, No MOQ needed We comply with all the worldwide specifications, such as ISO9001 and TS16949 standards.

Overview

Fast Information

-

Shear bolt torque limiter (SB) EPG Team provides large top quality PTO shafts with tubes fastened by spring pin, cross joints with roller bearings with rollers

- Relevant Industries:

-

Producing Plant

- Model Name:

-

OEM

- OEM Service:

-

Help.

- Tolerance:

-

.01-.05mm or Personalized.

- Certification:

-

ISO9001, SGS.

- Area Treatment:

-

Sandblasting,Polishing,Anodize, Zinc,Nickel,Chrome,PlatinThe business masking 88,000 sq. meters, has innovative equipment and robust technical energy, these kinds of as the numerical control equipment equipment and machining centers, CAD/CAM system, industrial robot etc. g, and many others.

- Application:

-

Vehicle,Health care Equipments,Electric powered Appliance,Hardware,and many others.

- Dimension:

-

As Customers’ Request.

- Tools:

-

Milling/Lathe/Drilling/Four/3 Axis CNC Machining Middle

- Drawing Structure:

-

Pro/E, Automobile CAD, Strong Performs,IGS,UG, CAD/CAM/CAE

With its other characteristics, as NITRILE-BUTADIENE rubber ring seals ñ according to DIN 3760 regulation -, higher quality bearings, and an aluminium end, this item is the ideal decision within this productís household in the gears marketplace.

Offer Potential

- Offer Ability:

- a hundred thousand Piece/Parts for every Month

Packaging & Delivery

- Port

- Ningbo, Shanghai

-

Guide Time

: -

Amount(Luggage) 1 – five hundred >500 Est. Time(times) 30 To be negotiated

On-line Customization

|

Solution Title |

Substantial precision personalized cnc machining areas aluminum cnc turning parts |

|

Merchandise Variety |

CNC turning, milling, drilling, grinding, wire EDM reducing and many others. |

|

Our Providers |

CNC Machining,Plastic Injection,Stamping,Die Casting,Silicone And Rubber,Aluminum Extrusion,Mould Producing,and so on |

|

Materials |

Aluminum,Brass,Stainless Metal,Copper,Plastic,Wooden,Silicone,Rubber,Or as for every the customers’ needs |

|

Surface Remedy |

Anodizing,Sandblasting,Painting,Powder coating,Plating,Silk Printing,Brushing,Sharpening,Laser Engraving |

|

Dimension |

As customers’ request |

|

Provider Venture |

To supply manufacturing design and style, creation and technological support, mould growth and processing, and so on |

|

Drawing Format |

Professional/E, Vehicle CAD, Reliable Works,IGS,UG, CAD/CAM/CAE |

|

Tests Device |

Digital Peak Gauge, caliper, Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on |

|

Sector used |

Equipment heavy responsibility gear electronic device Car spare parts optical telecommunication |

|

Packing |

Eco-pleasant pp bag / EPE Foam /Carton packing containers or picket packing containers |

|

Demo sample time |

7-ten days after confirmation |

|

Supply time |

seven-30 days following receive the pre-payments |

|

Payment Conditions |

T/T,Western Union,Paypal |

Best China manufacturer & factory wholesale high quality cnc stainless steel precision machining parts With high quality best price

With many years’ experience in these lines, we have been distinguished from other suppliers in China by our advantages in competitive pricing, on-time delivery, prompt responses, on-hand engineering support and good after-sales services.Once the PTO has begun to power the attachment, steadily increase the throttle until you reach the operating speed. The typical running RPM (revolutions per minute) for a tractor mounted PTO is 540 RPM, although there are tractor models that rev higher. Always refer to your particular tractor model for instructions prior to first-time use.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Brand Name:

-

OEM

- OEM Service:

-

Support

- Tolerance:

-

0.01-0.05mm or Customized

- Certification:

-

ISO9001, SGS

- Surface Treatment:

-

Sandblasting,Polishing,Anodize, Zinc,Nickel,Chrome,Plating, etc.

- Application:

-

Automobile,Medical Equipments,Electric Appliance,Hardware,etc.

- Dimension:

-

As Customers’ Request

- Equipment:

-

Milling/Lathe/Drilling/Four/Three Axis CNC Machining Center

- Drawing Format:

-

PRO/E, Auto CAD, Solid Works,IGS,UG, CAD/CAM/CAE

Supply Ability

- Supply Ability:

- 10000 Piece/Pieces per Month

Packaging & Delivery

- Port

- nb

-

Lead Time

: -

Quantity(Pieces) 1 – 500 >500 Est. Time(days) 30 To be negotiated

Online Customization

|

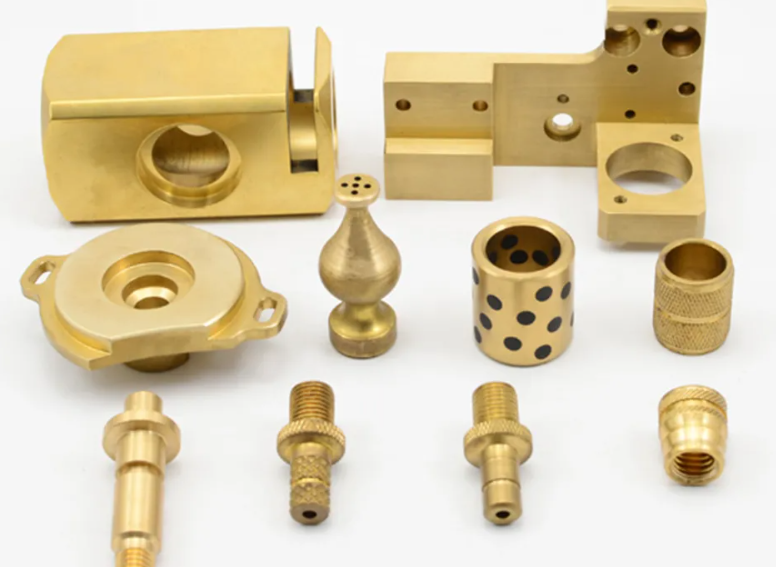

Product Name |

wholesale high quality cnc stainless steel precision machining parts |

|

Product Type |

CNC turning, milling, drilling, grinding, wire EDM cutting etc. |

|

Our Services |

CNC Machining,Plastic Injection,Stamping,Die Casting,Silicone And Rubber,Aluminum Extrusion,Mould Making,etc |

|

Material |

Aluminum,Brass,Stainless Steel,Copper,Plastic,Wood,Silicone,Rubber,Or as per the customers’ requirements |

|

Surface Treatment |

Anodizing,Sandblasting,Painting,Powder coating,Plating,Silk Printing,Brushing,Polishing,Laser Engraving |

|

Dimension |

As customers’ request |

|

Service Project |

To provide production design, production and technical service, mould development and processing, etc |

|

Drawing Format |

PRO/E, Auto CAD, Solid Works,IGS,UG, CAD/CAM/CAE |

|

Testing Machine |

Digital Height Gauge, caliper, Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on |

|

Industry used |

Machinery; heavy duty equipment; electronic device; Auto spare parts; optical telecommunication |

|

Packing |

Eco-friendly pp bag / EPE Foam /Carton boxes or wooden boxes |

|

Trial sample time |

7-10 days “EPG” brand rotocultivator ploughshares in T.S. total lines produced in our factory have been tested and appraised by the Ministry of Agriculture and have obtained the license of popularizing farm machinery promulgated by the Ministry of Agriculture of the People’s Republic of China. after confirmation |

|

Delivery time |

7-30 days after receive the pre-payments |

|

Payment Terms |

T/T,Western Union,Paypal |

EPG clearly selects as target the constant improvement; it has always been a precursor of new markets and production techniques. We devote more than 6% of our profits, and almost 4% of the EBITDA, to Research and Development. Therefore, we are able to offer to our customers exclusive made-to-measure products.

Best China manufacturer & factory Professional Manufacturer High Technology aluminum machining cnc auto parts german cars With high quality best price

Our product range also covers locking assemblies (clamping elements/locking device), taper bushes, QD bushes, bolt-on hubs, pto shaft, agricultural gearboxes,torque limiters, shaft collars, motor bases and motor slides, chain detachers, chain guides, universal joint, rod ends and yokes.

Our products is popular exported to the United States, Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Middle and South America, Thailand, Pakistan, Indonesia, more than 60 countries and regions.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Brand Name:

-

OEM

- OEM Service:

-

Support

- Tolerance:

-

0.01-0.05mm or Customized

- Certification:

-

ISO9001, SGS

- Surface Treatment:

-

Sandblasting,Polishing,Anodize, Zinc,Nickel,Chrome,Plating, etc.

- Application:

-

Automobile,Medical Equipments,Electric Appliance,Hardware,etc.

- Dimension:

-

As Customers’ Request

- Equipment:

-

Milling/Lathe/Drilling/Four/Three Axis CNC Machining Center

- Drawing Format:

-

PRO/E, Auto CAD, Solid Works,IGS,UG, CAD/CAM/CAE

Supply Ability

- Supply Ability:

- 10000 Piece/Pieces per Month

Packaging & Delivery

- Port

- nb

while the types of yokes for the connection of the PTO shafts with the agricultural implement includes the same above splined yokes and also yokes with recessed button and/or ball collar with:

-

Lead Time

: -

Quantity(Pieces) 1 – 500 >500 Est. Time(days) 30 To be negotiated

Online Customization

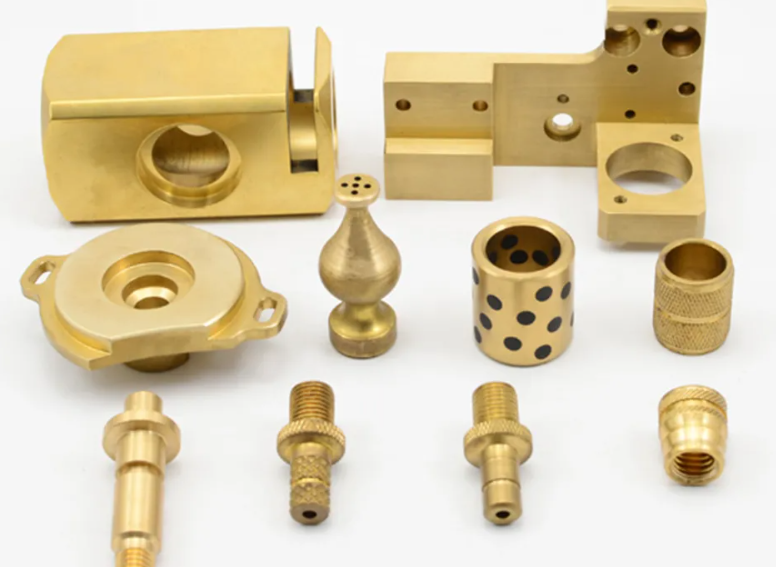

Professional Manufacturer High Technology aluminum machining cnc auto parts german cars

Product Description

| Product Type | CNC turning, milling, drilling, grinding, wire EDM cutting etc. |

| Our Services | CNC Machining,Plastic Injection,Stamping,Die Casting,Silicone And Rubber,Aluminum Extrusion,Mould Making,etc |

| Material | Aluminum,Brass,Stainless Steel,Copper,Plastic,Wood,Silicone,Rubber,Or as per the customers’ requirements |

| Surface Treatment |

Anodizing,Sandblasting,Painting,Powder coating,Plating,Silk Printing,Brushing,Polishing,Laser Engraving |

| Dimension | As customers’ request |

| Service Project | To provide production design, production and technical service, mould development and proThe Series B EPG x right angle worm geared motors and reducers provide a highly flexible and compact solution to meet the low to medium power range. With power capabilities up to 20HP and maximum output torque capacity of 5,000 lb in., the Series B can provide design flexibility with lasting performance. The Series B benefits from more than 200 years of cumulative experience in the design and manufacture of high quality mechanical power transmission solutions. With features like our patented motor connection and the unique Swift Kit concept, Series B is the answer for your right angle drive requirements.cessing, etc |

| Drawing Format: | PRO/E, Auto CAD, Solid Works,IGS,UG, CAD/CAM/CAE |

| Testing Machine | Digital Height Gauge, caliper, Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on |

| Industry used | Machinery; heavy duty equipment; electronic device; Auto spare parts; optical telecommunication |

| Packing | Eco-friendly pp bag / EPE Foam /Carton boxes or wooden boxes As customer’s specific requirements |

| Trial sample time | 7-10 days after confirmation |

| Delivery time | 7-30 days after receive the pre-payments |

| Payment Terms | T/T,Western Union,Paypal |

OEM Service

OEM Parts

Surface Treatment

Production Process

Why Us

Hot China sell sheet metal cnc machining parts service part of sewing machine – Supplier Manufacturer wholesaler Factory

For far more information.: Cellular/Whatpp: +8613083988828

After the PTO has started to electricity the attachment, steadily improve the throttle until you achieve the working velocity. The typical managing RPM (revolutions for each moment) for a tractor mounted PTO is 540 RPM, despite the fact that there are tractor designs that rev larger. Usually refer to your particular tractor product for instructions prior to 1st-time use.A formal quality assurance system with TS16949 certification insure that the completed products meet the consumers specifications. And we also have very prosperous international trade knowledge for many years. So we do think we can offer the ideal service to you. Our main goods are Needle Roller bearings, Cylindrical Roller Bearings, Rod end Bearings, Spherical simple bearings, Monitor roller Bearings for Guideway, Roller Bearings, Combine Bearings for forklifts, Water Pump Bearings, SNR Car Bearings and all types of Spherical Bearings. Our goods is popular exported to the United States, Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Center and South The usa, Thailand, Pakistan, Indonesia, a lot more than sixty nations around the world and locations.

Overview

Quick Specifics

- Applicable Industries:

-

Production Plant

- Manufacturer Name:

-

OEM

- OEM Services:

-

Support

- Tolerance:

-

.01-.05mm or Custom-made

- Certification:

-

ISO9001, SGS

- Area Treatment:

-

Sandblasting,Sprucing,Anodize, Zinc,Nickel,Chrome,Plating, and many others.

- Application:

-

Automobile,Healthcare Equipments,Electric powered Appliance,Components,and so forth.

- Dimension:

-

As Customers’ Ask for

- Gear:

-

Milling/Lathe/Drilling/Four/Three Axis CNC Machining Heart

- Drawing Format:

-

Professional/E, Car CAD, Reliable Works,IGS,UG, CAD/CAM/CAE

Source Potential

- Provide Capability:

- 10000 Piece/Items for every Month

Packaging & Delivery

- Port

- nb

-

Guide Time

: -

Quantity(Pieces) 1 – five hundred >500 Est. Time(times) 30 To be negotiated

On the web Customization

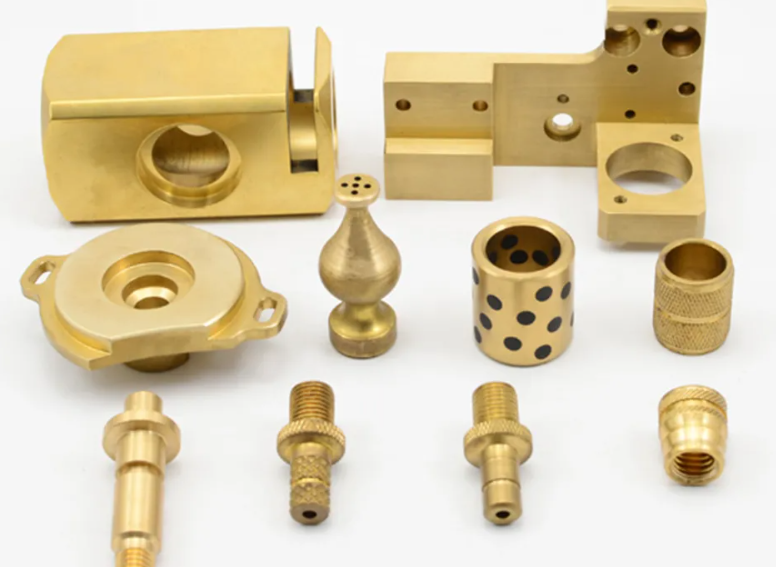

Sizzling market sheet metal cnc machining elements service element of stitching device

Merchandise Description

| Product Sort | CNC turning, milling, drilling, grinding, wire EDM cutting and so on. |

| Our Providers | CNC Machining,Plastic Injection,Stamping,Die Casting,Silicone And Rubber,Aluminum Extrusion,Mould Making,etc |

| Material | Aluminum,Brass,Stainless Metal,Copper,Plastic,Wooden,Silicone,Rubber,Or as for every the customers’ demands |

| Surface Remedy |

Anodizing,Sandblasting,Painting,Powder coating,Plating,Silk Printing,Brushing,Polishing,Laser Engraving |

| Dimension | As customers’ request |

| Service Task | To provide creation layout, manufacturing and complex services, mould development and processing, and many others |

| Drawing Structure: | PRO/E, Auto CAD, Solid Works,IGS,UG, CAD/CAM/CAE |

| Testing Equipment | Digital Peak Gauge, caliper, Coordinate measuring equipment, projection equipment, roughness tester, hardness tester and so on |

| Industry used | Machinery weighty obligation tools electronic system Vehicle spare areas optical telecommunication |

| Packing | Eco-pleasant pp bag / EPE Foam /Carton packing containers or wooden boxes As customer’s distinct demands |

| Trial sample time | 7-ten days soon after confirmation |

| Delivery time | 7-30 times after receive the pre-payments |

| Payment Phrases | T/T,Western Union,Paypal |

OEM Provider

OEM Areas

Surface area Remedy

Generation Approach

Why Us

EPG – a single of the most significant transmission manufacturing unit in China, main items: worm geared motors, agricultrual gearbox, planetary equipment travel, helical,screw, beve gears and spare areas and agricultural parts manunfacuter in China /For much more data.: Cell/Whatpp: +8613083988828

OEM Manufacturers & Suppliers manufacturing precision aluminum cnc machining coffee filter

Our professionals and engineers have 23 many years of Experience in the Bearing Business.

Overview

Quick Particulars

- Relevant Industries:

-

Producing Plant

- Brand Title:

-

OEM

- OEM Support:

-

Support

- Tolerance:

-

.01-.05mm or Custom-made

- Area Treatment method:

-

Sandblasting,Polishing,Anodize, Zinc,Nickel,Chrome,Plating, and so forth.

- Application:

-

Vehicle,Health care Equipments,Electrical Appliance,Components,and many others.

- Dimension:

-

As Customers’ Request

- Equipment:

-

Milling/Lathe/Drilling/4/Three Axis CNC Machining Center

- Drawing Structure:

-

Professional/E, Automobile CAD, Reliable Operates,IGS,UG, CAD/CAM/CAE

Source Capability

- Source Ability:

- 10000 Piece/Items per Thirty day period

Packaging & Shipping and delivery

- Port

- nb

-

Guide Time

: -

Quantity(Pieces) one – five hundred >500 Est. Time(times) 30 To be negotiated

Online Customization

|

Product Type |

CNC turning, milling, drilling, grinding, wire EDM cutting and so forth. |

|

Our Companies |

CNC Machining,Plastic Injection,Stamping,Die Casting,Silicone And Rubber,Aluminum Extrusion,Mould Producing,and so on |

|

Material |

Aluminum,Brass,Stainless Metal,Copper,Plastic,Wooden,Silicone,Rubber,Or as per the customers’ needs |

|

Surface Remedy |

Anodizing,Sandblasting,Portray,Powder coating,Plating,Silk Printing,Brushing,Sprucing,Laser Engraving |

|

Dimension |

As customers’ request |

|

Services Project |

To provide manufacturing style, creation and specialized support, mould growth and processing, and so on |

|

Drawing Structure |

Professional/E, Automobile CAD, Sound Functions,IGS,UG, CAD/CAM/CAE |

|

Testing Device |

Digital Peak Gauge, caliper, Coordinate measuring machine, projection equipment, roughness tester, hardness tester and so on |

|

Industry utilised |

Equipment large duty tools digital device Automobile spare parts optical telecommunication |

|

Packing |

Eco-welcoming pp bag / EPE Foam /Carton containers or picket containers |

|

Demo sample time |

seven-ten days soon after affirmation |

|

Delivery time |

7-thirty times after receive the pre-payments |

|

Payment Phrases |

T/T,Western Union,Paypal |