Product Description

Product Description

Product Parameters

| product | Star Elastic with Enlarged Shaft Hole Flexible Coupling for Machine tools |

| material | stainless steel , iron , aluminum ,bronze ,carbon steel ,brass etc . |

| size | ISO standard ,customer requirements |

| BORE | Finished bore, Pilot Bore, Special request |

| surface treatment | Carburizing and Quenching,Tempering ,Tooth suface high quenching Hardening,Tempering |

| Processing Method | Molding, Shaving, Hobbing, Drilling, Tapping, Reaming, Manual Chamfering, Grinding etc |

| Heat Treatment | Quenching & Tempering, Carburizing & Quenching, High-frequency Hardening, Carbonitriding…… |

| Package | Wooden Case/Container and pallet, or made-to-order |

| Certificate | ISO9001 ,SGS |

| Machining Process | Gear Hobbing, Gear Milling, Gear Shaping, Gear Broaching, Gear Shaving, Gear Grinding and Gear Lapping |

| Applications | Toy, Automotive, instrument, electrical equipment, household appliances, furniture, mechanical equipment,daily living equipment, electronic sports equipment, , sanitation machinery, market/ hotel equipment supplies, etc. |

| Testing Equipment | Rockwell hardness tester 500RA, Double mesh instrument HD-200B & 3102,Gear measurement center instrument CNC3906T and other High precision detection equipments |

workshop & equipment

Production process

Certifications

Our Advantages

1 . Prioritized Quality

2 .Integrity-based Management

3 .Service Orientation

4 .150+ advanced equipment

5 .10000+ square meter factory area

6 .200+ outstanding employees

7 .90% employees have more than 10 year- working experience in our factory

8 .36 technical staff

9 .certificate ISO 9001 , SGS

10 . Customization support

11 .Excellent after-sales service

shipping

sample orders delivery time:

10-15 working days as usual

15-20 working days in busy season

large order leading time :

20-30 working days as usual

30-40 working days in busy season

FAQ

1. why should you buy products from us not from other suppliers?

We are a 32 year-experience manufacturer on making the gear, specializing in manufacturing varieties of gears, such as helical gear ,bevel gear ,spur gear and grinding gear, gear shaft, timing pulley, rack, , timing pulley and other transmission parts . There are 150+ advanced equipment ,200+ excellent employees ,and 36 technical staff . what’s more ,we have got ISO9001 and SGS certificate .

2 .Do you accept small order?

If your order bearings are our standard size, we accept even 1pcs.

3 .How long is the delivery?

A: Small orders usually takes 10-15 working days,big order usually 20-35 days, depending on orders quantity and whether are standard size.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

How do flexible couplings handle axial movement in rotating machinery?

Flexible couplings are designed to handle different types of misalignments in rotating machinery, including axial movement or axial misalignment. Axial movement occurs when there is displacement along the axis of rotation, causing one shaft to move closer to or away from the other shaft. Here’s how flexible couplings handle axial movement:

- Sliding Capability: Many flexible couplings, especially those with elastomeric elements or certain designs, can slide along the shafts they connect. This sliding capability allows the coupling to accommodate axial movement without introducing additional stress on the connected components. The elastomeric elements can compress or stretch slightly to absorb the axial displacement.

- Multiple-piece Designs: Some flexible couplings consist of multiple pieces, which allow for axial movement. These designs often have a floating member or a spacer that separates the two shaft-connected components. The floating member can move axially as needed, while still transmitting torque and compensating for other misalignments.

- Double-Cardanic Design: Certain high-performance flexible couplings use a double-cardanic design, allowing for misalignment in multiple directions, including axial movement. This design features two sets of flexible elements that work together to accommodate different misalignments and provide a high degree of flexibility.

It’s important to note that while flexible couplings can handle a certain degree of axial movement, excessive axial misalignment might require a different type of coupling or additional measures to be addressed properly.

During the selection and installation process, it’s essential to consider the application’s axial movement requirements and choose a flexible coupling that can accommodate the expected axial displacement while still providing the desired performance, such as vibration damping, shock absorption, or precision motion control.

What are the key considerations for selecting a flexible coupling for high-speed applications?

When selecting a flexible coupling for high-speed applications, several critical considerations should be taken into account to ensure optimal performance and reliability:

- Material and Design: Choose a flexible coupling made from high-quality materials that can withstand the high rotational speeds without experiencing excessive wear or fatigue. Consider designs that are specifically engineered for high-speed applications, ensuring they have the required torsional stiffness and damping characteristics.

- Balance: Imbalance at high speeds can lead to vibration and reduce the lifespan of the coupling and connected components. Look for precision-balanced flexible couplings that minimize vibration and avoid any potential resonance issues at operating speeds.

- Torsional Stiffness: In high-speed applications, torsional stiffness is crucial to maintaining accurate rotational timing and preventing torque losses. Choose a flexible coupling with adequate torsional stiffness to minimize angular deflection under load.

- Dynamic Balancing: Dynamic balancing is essential for flexible couplings used in high-speed applications. A dynamically balanced coupling reduces vibrations caused by rotational imbalances, increasing the smoothness and stability of the system.

- Temperature Resistance: High-speed operations can generate significant heat, so select a flexible coupling that can withstand the elevated temperatures without compromising its mechanical properties or causing premature failure.

- Alignment and Runout Tolerance: Accurate alignment of the coupling with the shafts is crucial to prevent additional stress and vibration. Consider couplings with high runout tolerance and ease of alignment to facilitate proper installation.

- Service Life and Maintenance: Evaluate the expected service life of the flexible coupling in high-speed applications. Low-maintenance couplings are desirable to reduce downtime and maintenance costs.

- Application Specifics: Consider the specific requirements of the high-speed application, such as the magnitude of torque, axial movement, and the presence of shock loads. Choose a coupling that can handle these specific demands while maintaining performance at high speeds.

- Compliance with Standards: Ensure that the selected flexible coupling complies with relevant industry standards and specifications, especially those related to high-speed performance and safety.

By carefully considering these key factors, engineers can choose a flexible coupling that meets the demands of high-speed applications, delivering reliable and efficient power transmission while minimizing the risk of premature wear, vibration, and downtime.

How does a flexible coupling affect the noise and vibration levels in a mechanical system?

A flexible coupling plays a crucial role in controlling noise and vibration levels in a mechanical system. It can significantly impact the overall smoothness and quietness of the system’s operation, contributing to enhanced performance and reduced wear on connected components.

Noise Reduction:

Flexible couplings help reduce noise in a mechanical system through their inherent ability to dampen vibrations. When the shafts of rotating machinery are not perfectly aligned, it can lead to vibrations that are transmitted throughout the system, resulting in noise generation. The elastomeric or flexible element of the coupling acts as a vibration dampener, absorbing and dissipating these vibrations. As a result, the noise levels in the system are reduced, creating a quieter operating environment.

Vibration Damping:

Vibrations in a mechanical system can lead to increased wear and tear on critical components, such as bearings, seals, and gears. Excessive vibrations can also cause resonance and damage to the system over time. Flexible couplings can effectively dampen vibrations by acting as a buffer between the driving and driven shafts. The flexible element absorbs the shock and vibrations, preventing them from propagating to other parts of the system. This vibration damping capability not only reduces noise but also protects the system from potential mechanical failures, extending the lifespan of the equipment.

Alignment Compensation:

Misalignment between shafts is a common cause of vibration and noise in rotating machinery. Flexible couplings excel at compensating for both angular and parallel misalignment. By accommodating misalignment, the coupling reduces the forces acting on the shafts and minimizes the generation of vibrations and noise. Proper alignment through the use of a flexible coupling ensures that the system operates smoothly and quietly.

Effect on Equipment Reliability:

Reducing noise and vibration levels has a positive impact on the reliability of connected equipment. Lower vibrations mean less stress on bearings and other rotating components, leading to extended component life and reduced maintenance requirements. A quieter operating environment can also be essential for certain applications, such as in laboratories or precision manufacturing processes, where excessive noise can interfere with delicate tasks or measurements.

Applications:

Flexible couplings find application in a wide range of industries, such as manufacturing, power generation, material handling, automotive, aerospace, and robotics. They are commonly used in pumps, compressors, fans, conveyors, and other rotating machinery where noise and vibration control are critical for smooth and reliable operation.

Summary:

A flexible coupling’s ability to reduce noise and dampen vibrations makes it an essential component in mechanical systems. By compensating for misalignment and providing vibration dampening properties, the flexible coupling enhances the overall system performance, reduces noise levels, and protects connected equipment from excessive wear and mechanical failures. Choosing the right type of flexible coupling based on the specific application requirements can have a significant impact on noise reduction and vibration control in the mechanical system.

editor by CX 2024-03-27

China manufacturer Star Elastic with Enlarged Shaft Hole Flexible Coupling for Machine Tools

Product Description

Product Description

Product Parameters

| product | Star Elastic with Enlarged Shaft Hole Flexible Coupling for Machine tools |

| material | stainless steel , iron , aluminum ,bronze ,carbon steel ,brass etc . |

| size | ISO standard ,customer requirements |

| BORE | Finished bore, Pilot Bore, Special request |

| surface treatment | Carburizing and Quenching,Tempering ,Tooth suface high quenching Hardening,Tempering |

| Processing Method | Molding, Shaving, Hobbing, Drilling, Tapping, Reaming, Manual Chamfering, Grinding etc |

| Heat Treatment | Quenching & Tempering, Carburizing & Quenching, High-frequency Hardening, Carbonitriding…… |

| Package | Wooden Case/Container and pallet, or made-to-order |

| Certificate | ISO9001 ,SGS |

| Machining Process | Gear Hobbing, Gear Milling, Gear Shaping, Gear Broaching, Gear Shaving, Gear Grinding and Gear Lapping |

| Applications | Toy, Automotive, instrument, electrical equipment, household appliances, furniture, mechanical equipment,daily living equipment, electronic sports equipment, , sanitation machinery, market/ hotel equipment supplies, etc. |

| Testing Equipment | Rockwell hardness tester 500RA, Double mesh instrument HD-200B & 3102,Gear measurement center instrument CNC3906T and other High precision detection equipments |

workshop & equipment

Production process

Certifications

Our Advantages

1 . Prioritized Quality

2 .Integrity-based Management

3 .Service Orientation

4 .150+ advanced equipment

5 .10000+ square meter factory area

6 .200+ outstanding employees

7 .90% employees have more than 10 year- working experience in our factory

8 .36 technical staff

9 .certificate ISO 9001 , SGS

10 . Customization support

11 .Excellent after-sales service

shipping

sample orders delivery time:

10-15 working days as usual

15-20 working days in busy season

large order leading time :

20-30 working days as usual

30-40 working days in busy season

FAQ

1. why should you buy products from us not from other suppliers?

We are a 32 year-experience manufacturer on making the gear, specializing in manufacturing varieties of gears, such as helical gear ,bevel gear ,spur gear and grinding gear, gear shaft, timing pulley, rack, , timing pulley and other transmission parts . There are 150+ advanced equipment ,200+ excellent employees ,and 36 technical staff . what’s more ,we have got ISO9001 and SGS certificate .

2 .Do you accept small order?

If your order bearings are our standard size, we accept even 1pcs.

3 .How long is the delivery?

A: Small orders usually takes 10-15 working days,big order usually 20-35 days, depending on orders quantity and whether are standard size.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

How do flexible couplings handle shaft misalignment in rotating equipment?

Flexible couplings are designed to handle shaft misalignment in rotating equipment, providing several key features that allow them to accommodate misalignment effectively. Here’s how they work:

- Angular Misalignment: Flexible couplings can handle angular misalignment, which occurs when the axes of the connected shafts are not perfectly aligned. The coupling’s flexible elements allow for slight angular deviation, ensuring that the torque can still be transmitted smoothly between the shafts.

- Parallel Misalignment: Parallel misalignment occurs when the connected shafts are not perfectly in line but run parallel to each other. Flexible couplings can compensate for this misalignment by utilizing their ability to flex or slide, allowing the shafts to remain connected while maintaining rotational integrity.

- Axial Misalignment: Axial misalignment refers to the situation where the connected shafts have a slight axial displacement. Some flexible couplings have specific designs to handle axial misalignment, allowing for limited movement along the axial direction without compromising the connection between the shafts.

- Double Flexing: Certain types of flexible couplings, such as the double-flexing couplings, can accommodate both angular and parallel misalignments simultaneously. These couplings use two sets of flexible elements to achieve this capability, providing a higher degree of misalignment compensation.

Overall, the flexibility of the coupling’s material and design allows it to bend, flex, or slide in response to the misalignment, reducing the stress on the connected equipment and ensuring smooth power transmission. By accommodating misalignment, flexible couplings help prevent premature wear, reduce vibration, and extend the service life of the rotating equipment.

How does a flexible coupling handle misalignment in large rotating equipment?

Flexible couplings are designed to accommodate various types of misalignment in large rotating equipment, ensuring smooth and efficient power transmission while minimizing stress on connected components. Here’s how flexible couplings handle different types of misalignment:

- Angular Misalignment: Angular misalignment occurs when the axes of the two connected shafts are not collinear and form an angle. Flexible couplings can handle angular misalignment by allowing the coupling elements to flex and move slightly, thus accommodating the angle between the shafts. The flexible elements, often made of elastomeric materials or metallic membranes, can bend and twist to compensate for angular misalignment, ensuring that the coupling remains engaged and transfers torque effectively.

- Parallel Misalignment: Parallel misalignment, also known as offset misalignment, happens when the two shafts are not perfectly aligned along their axes, resulting in a lateral shift. Flexible couplings can handle parallel misalignment through their ability to move radially, allowing the flexible elements to adjust and take up the offset. This capability prevents excessive side loads on the shafts and bearings, reducing wear and increasing the lifespan of the equipment.

- Axial Misalignment: Axial misalignment occurs when there is a linear displacement of one shaft relative to the other, either toward or away from the other shaft. Some flexible couplings, such as certain types of flexible disc couplings, can accommodate a limited amount of axial misalignment. However, for large axial movement, other types of couplings or special designs may be required.

The flexibility of the coupling elements allows them to act as a buffer between the shafts, dampening shocks, vibrations, and torsional forces caused by misalignment or other dynamic loads. This helps protect the connected equipment from damage and enhances the overall performance and reliability of the rotating system.

In large rotating equipment, where misalignment is more common due to thermal expansion, foundation settling, or other factors, flexible couplings play a critical role in maintaining smooth operation and reducing stress on the machinery. However, it is essential to choose the appropriate type of flexible coupling based on the specific requirements of the application and to regularly inspect and maintain the coupling to ensure optimal performance and longevity.

What are the maintenance requirements for flexible couplings?

Maintenance of flexible couplings is essential to ensure their reliable and efficient performance over their service life. Proper maintenance helps prevent premature wear, reduces the risk of unexpected failures, and extends the lifespan of the couplings. Here are some key maintenance requirements for flexible couplings:

- Regular Inspection: Perform regular visual inspections of the flexible couplings to check for signs of wear, damage, or misalignment. Look for cracks, tears, or any other visible issues in the coupling components.

- Lubrication: Some flexible couplings, especially those with moving parts or sliding surfaces, may require periodic lubrication. Follow the manufacturer’s recommendations regarding the type and frequency of lubrication to ensure smooth operation.

- Alignment Checks: Misalignment is a common cause of coupling failure. Regularly check the alignment of the connected shafts and adjust as necessary. Proper alignment reduces stress on the coupling and improves power transmission efficiency.

- Torque Monitoring: Monitoring the torque transmitted through the coupling can help detect any abnormal or excessive loads. If the coupling is subjected to loads beyond its rated capacity, it may lead to premature failure.

- Environmental Protection: If the couplings are exposed to harsh environmental conditions, take measures to protect them from dust, dirt, moisture, and corrosive substances. Consider using protective covers or seals to shield the couplings from potential contaminants.

- Temperature Considerations: Ensure that the operating temperature of the flexible coupling is within its designed range. Excessive heat can accelerate wear, while extremely low temperatures may affect the flexibility of certain coupling materials.

- Replace Worn or Damaged Parts: If any components of the flexible coupling show signs of wear or damage, replace them promptly with genuine replacement parts from the manufacturer.

- Manufacturer’s Guidelines: Follow the maintenance guidelines provided by the coupling manufacturer. They often include specific maintenance intervals and procedures tailored to the coupling’s design and materials.

- Training and Expertise: Ensure that maintenance personnel have the necessary training and expertise to inspect and maintain the flexible couplings properly. Improper maintenance practices can lead to further issues and compromise the coupling’s performance.

By adhering to these maintenance requirements, you can maximize the service life of the flexible couplings and minimize the risk of unexpected downtime or costly repairs. Regular maintenance helps maintain the efficiency and reliability of the coupling in various industrial, automotive, and machinery applications.

editor by CX 2024-03-18

1325 made in China – replacement parts – in Jubayl Saudi Arabia Three Heads MDF Wood CNC Router Machine for Engraving with ce certificate top quality low price

We – EPG Group the bigge EPT Chain and agricultural gearbox manufacturing facility in China with 5 diverse branches. For more specifics: Cellular/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Just before you study our this cnc device specifcations and value, i mu EPT have to say to you friend, the price we write, it is FOB HangZhou value. It is not EXW price tag. EXW cost only is machine value. Our FOB HangZhou value=EXW price tag+plywood circumstance packing charges+freight charges from us to HangZhou port+HangZhou port costs. Thank you! Make sure you note cautiously!

1325 3 Heads mdf wood CNC Router Equipment for Engraving

Attributes of Affordable 4×8 CNC Router with Multi-spindles:

1. Top Manufacturer Square Linear Rail, substantial accuracy, hefty burthen.

2. High accuracy Rack Rail travel technique with higher speed.

3. Lathe bed adopts sturdy welded steel tube to steer clear of distortion.

four. Superior worldwide technology vacuum with double cavity.

5. Y axis adopts double motors to keep steady transferring.

6. Intelligent defending doing work fable.

7. Xihu (We EPT Lake) Dis.nization style of lathe mattress vacuum and simple to operate.

8. Two, 3 or four spindles change automatically with larger overall performance.

-3.5kw air cooling spindle*3

-Leadshine servo with SHIMPO reducer motor and driver

-Weihong 3L handle method

-3.7kw fulling inverter

-4.0kw du EPT collector

Technological specification of cnc router:

| Regular | CE and ISO |

| Model | 1325,1530, 2030 |

| Working location(x,y,z axis) | 1300x2500mm,1500x3000mm,2000x3000mm |

| Spindle | 3.5kw air cooling spindle*3 |

| Manage technique | EPT weihong 3L |

| Motor | Leadshine servo with SHIMPO reducer |

| Inverter | three.7kw Fulling inverter |

| X Y Z axis | EPT ZheJiang Hiwin square rai EPT twenty five |

| Transmission | XY axis is gear rack transmission, Z axis is ZheJiang TBI ballscrew transmission |

| If have vacuum pump | Sure, consist of 5.5kw (Remember to observe this) |

| Table | Vacuum adsorption desk |

| Composition | Large thick steel tube welded |

| Lubrication | Automated Lubrication program |

| If have the du EPT collector | Of course, consist of 4.0kw double sort |

| Device Box | All the common also EPT incorporated |

| minimal switch | Japan Omron higher sensitivity constrained swap |

| parts | France Schneider electronic components |

| EPT elements | Tool sensor, resources, and so forth… |

| 4th Rotary axis | count on Customer |

| EPT cnc router types | 400x400mm,600x900mm,1200x1200mm,1200X1800mm, 900x1500mm,1200x2400mm,9500x2000mm,1300x2500mm,1500x3000mm, 2000x3000mm,ATC1325,ATC1218,ATC6090,Multi heads cnc routers |

| Weight | 1400kgs |

| Dimensions | Machine:3800*2200*18000mm |

| Delivery time(times) | one-1set 2-3 sets 4-5 sets >6 sets |

| 25 40 50 To be negotiation |

1325 a few Heads mdf wooden CNC Router Machine for Engraving

Detai EPT of cnc router:

Software Sector and Materia EPT of cnc router:

Woodworking Business:Cnc router can be utilized for reliable wooden furnishings,mahogany furniture,MDF paint doorways,reliable wood doorways,composite doorways,

cupboard doorways and home windows,beside cabinets,folding screen and so forth. cnc wooden cutter

The advertising Market:Cnc router can engrave all types of signage,logo products,logos,nameplates,badges,decorative gift,embossed

medals,certificates,souvenirs,photograph frames,furniture decoration,PVC plates, PCB boards(drilling and engraving),Double color boards,acrylic and so forth.

Artwork Market: in the wooden, bamboo, organic board, double shade plate, crystal and EPT materia EPT on a variety of exquisite designs and text engraving.

Exhibition Market: Showcases, etc.

——-Packing and delivery——-

We have 3 levels deal.

or the outside, we adopt cost-free fumigation wood craft case.

In the center, the machine is covered by foam, to protect the equipment from shaking.

For the inside of layer, the device is covered by thickening plastic bag for water-proof.

1325 three Heads mdf wood CNC Router Machine for Engraving

Our Business cnc router:

HangZhou Starma EPT Gear Co.,Ltd. making cnc router is situated in HangZhou metropolis, ZheJiang province. We are a professional and great popularity company of CNC router,wooden cnc router, stone cnc router, laser engraving equipment, CNC plasma cutter, laser reducing equipment, laser marking equipment in China to the new and existing buyers that are spread all through the South The us, Center East, Southea EPT Asia, Africa, Europe and EPT counties of the globe and the devices has handed the EU CE certificate.The purpose of HangZhou STARMA CNC Router is to continually update the approach, to assist our customers create the be EPT good quality and large precision cnc routers and cnc devices.

Our service:

Prior to sale:

We would constantly be below to offer any info you require at the fir EPT time,and give specialist suggestions in accordance to your real requirements for free

Throughout sale:

We would deal with all the production and shipping and delivery affairs,soon after almost everything is prepared,we would inform you every little thing goes effectively listed here 4×8 toes cnc equipment

Right after sale:

We would supply English Version operating guide.

If you have any concerns throughout utilizing and sustaining,our engineers who could talk extremely good english would answer you on the internet or by calls.

Equipment warranty is 1 12 months.So if your equipment has any accidental damages,we would supply parts for cost-free.

If your machine has large problems if by any possibility,our engineers would get there there to debug and resolve.

our expert after sale services team which are chosen by really rigid exams,would pay out their 100% time and energy to resolve your difficulties!

FAQ:

one.How extended about the machine’s guarantee?

two many years

two.How about your after-product sales service ?

Specialized help by phone, WhatApp,Skype,e-mail or QQ all around the clock.

3.How can we install the equipment?

English variation handbook and procedure video clip CD disk.

4.How about the payment conditions?

30% T/T for deposit, 70%T/T compensated just before shipping. T/T, We EPT Union, Paypal

five.Do you Prepare Cargo For The Machines?

Yes, dear customers, for FOB or CIF cost, we will set up cargo for you.

For EXW cost, consumers need to set up shipment by on their own or their agents.

1325 3 Heads mdf wood CNC Router Device for Engraving

HangZhou Starma EPT Tools Co.,Ltd.

No ten-5.Fujia Industrial Park, Xihu (We EPT Lake) Dis. District,HangZhou,China

“Global Large End CNC Tools Manufactures ” —STARMAcnc Group

If you want to lear about far more of us, make sure you enter into our websit:

Much more details, you should You also can lookup us”STARMACNC” on youtube,facebook,linkdin,pin,google ,twitter,Tumblr,and so forth…

The use of original equipment manufacturer’s (OEM) element numbers or logos , e.g. CASE® and John Deere® are for reference functions only and for indicating merchandise use and compatibility. Our firm and the outlined replacement areas contained herein are not sponsored, accredited, or produced by the OEM.

High made in China – replacement parts – in Aurangabad India Efficiency CNC Router Woodworking Machine From China with ce certificate top quality low price

We – EPG Team the bigge EPT Chain and agricultural gearbox manufacturing unit in China with 5 diverse branches. For a lot more details: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

High Effectiveness CNC Router Woodworking Device from China

Technological parameters

| X,Y,Z Working Area | 1300x2500x250mm |

| X,Y,Z Repositioning Accuracy | ±0.05mm |

| Table Surface | T-slot Table |

| Frame | Welded structure |

| X, Y axis transmission | Rack and Pinion gear |

| Z transmission | Ball Screw |

| Rail Configuration | 20 square rail |

| Max. Traveling Rate | 25000mm/min |

| Max. Working Speed | 15000mm/min |

| Spindle Power | Drinking water cooling 3.0kw spindle |

| Spindle Speed | 24000RPM |

| Drive Motors | Stepper System |

| Working Voltage | AC220V/50Hz/3PH |

| Command Language | G Code |

| Operating System | Ncstudio Method (Opitional:DSP) |

| Computer Interface | USB |

| Software Compatibility | Type3,Wentai,Artcut (Option: ) |

| Packing Size | Wooden situation |

| N.W. | 1600Kg |

Marketing Woodworking CNC Router is created of substantial thickness square tube welded bed, China well-known model square rail and substantial rushing Stepper driver. It is suitable for cutting and engraving on diverse materia EPT this kind of as MDF, acrylic, wooden, PVC and so forth. And it is commonly utilized in advertising and marketing and woodworking industries. It is an financial kind CNC Router.

Applications:

1. Advertising products business: indicator producing, acrylic slicing and engraving.

two. Wood industry: wood furnishings making, 3d wooden relief carving, wood craftwork production Speakers, match consoles cupboards, pc tables, sewing equipment desk and so forth.

three. Board processing industry: insulation piece, acrylic board, plastic chemical goods, PCB, compact quality laminate, Ab muscles, PP, PE and EPT cementitious mixtures’s milling approach.

4. Decoration industry: folding display, wave plates, marketing boards, sign making and logo’s processing.

5. Arts & Crafts industries: Engrave on synthetic stones, woods, bamboos, marbles.

Workshop

Solution impact

RFQ

one. What is actually your delivery time?

It will get about twenty-30 times following obtaining the payment .

two.Which nation have you exported?

Our goods have exported to Indonesia, Korea, Vietnam, Pakistan, India, South Africa,Brazil,Peru and so on.

three What is the method of your payment?

T/T,irrevocable letter of credit history at sight

The use of unique equipment manufacturer’s (OEM) portion figures or emblems , e.g. CASE® and John Deere® are for reference needs only and for indicating product use and compatibility. Our organization and the listed substitution parts contained herein are not sponsored, authorized, or manufactured by the OEM.

China Roller chain and sprocket manufacturer Automatic system plast roller chain guide in Thiruvananthapuram India Wallpaper Heat Shrink Wrapping Machine Packaging Machine with ce certificate top quality low price

We – EPG Group the biggest Chain and agricultural gearbox manufacturing facility in China with 5 distinct branches.

we source chromed bar and tubes for hydualic and pheumatic cylinders, pto shaft, agricultural gearboxes etc. EPG The new merchandise contain a sequence of high-tech and high quality chains and sprockets and gears, these kinds of as chains and gearboxes for agricultural machineries, metallurgical chains, escalator action-chains, high-speed tooth chains, timing chains, self-lubrication chains, amid which have kind high velocity tooth chain for automobile branch dynamic box and aerial chains fill in the blanks of chain in China. is a major provider of high quality, expense-successful energy transmission elements. As our solution lines keep on to expand to meet our customer’s demands, our dedication to personalized buyer service and on-time delivery continues to be 2nd to none. We support a nationwide base of Industrial Distributors, and Authentic Products Manufacturers as effectively as Agricultural Gear Makers and Wholesalers. Located in Memphis, TN we are at the center of 1 of the biggest distribution hubs in the region and with our extensive inventory levels and unrestricted delivery possibilities, we are capable to offer our buyers with precise on-time deliveries. Description:

Gorgeous equipment, Secure top quality, Safety,strength preserving, patented goods, domestic initiative, software to the POF PVC PP film thermal shrink packaging influence is perfect.

Characteristics:

one.Look and knot design and style in accordance with national stHangZhourds, the fuselage utilizes fingerprint resistant sheet manufacturing right after spray remedy.

2.Management panel using programming system, 12V DC input , button swap , digital show.

3. Transmission utilizing 24v DC Motor speed management using variable frequency technology -9 file adjustment.

4.The conveyor belt can be used wire mesh belt, chain roller, Teflon mesh belt 3.

five.Heating using 600W 220V far infrared quartz heating tube.

6.Temperature manage using high precision intelligent temperature handle method . up and down temperature independent regulation.

seven.Sizzling air circulation employing 220V 60W 2200 to the extended axis motor with wind wheel.

8.The bracket can be disassembled , and the peak of the bracket can be altered.

| L SEALER | FQL 450 A | SHRINK TUNNEL | BSN 4571C |

| VOLTAGE | 220/fifty-60HZ | VOLTAGE | 380v fifty-60HZ |

| Electrical power | one.35KW | Energy | 9KW |

| AIR Force: | five-seven | TUNNEL Dimensions(L*W*H) | 1200*400x200mm |

| Ability | fifteen-30bags/min | Solution Dimension(W*H) | 350x150mm |

| Product MAX SIZE L+H(H<150mm) | <500mm | EPT Pace | -15m/min |

| Item MAX Size W+H(H<150mm) | < 400mm | Substance | CHAIN, TEFLON |

| SEALING Size | 550*450mm | CONVEYING LOAD | 20kg max |

| Device Dimension (L*W*H) | 1650*800*1450mm | Equipment Size (L*W*H) | 1600x560x660mm |

| Weight | 300KG | Weight | 80kg |

| Application: | POF.PE, | Software: | PE.POF |

The use of first tools manufacturer’s (OEM) portion numbers or emblems , e.g. CASE® and John Deere® are for reference purposes only and for indicating solution use and compatibility. Our organization and the shown substitution areas contained herein are not sponsored, approved, or manufactured by the OEM.

Colored made in China – replacement parts – in Toulouse France Steel Trapezoidal Roof Panel Cold Roll Forming Machine with ce certificate top quality low price

We – EPG Group the bigge EPT Chain and agricultural gearbox manufacturing unit in China with 5 distinct branches. For more particulars: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Trapezoid Roof Panel Roll Forming Device

Content

Powerful width: 914 mm

Content Thickness:.45-.9 mm

Relevant material: Prepainted galvanized steel(PPGI)

with yield power G235-G350

Pre-Cutting Devide

Main Machine

With feeding materials information, physique body created from H400 sort steel by welding

Side wall thickness: Q235 t18mm

Rollers manufactured from 45# steel,CNC lathes,Warmth Remedy,challenging Chrome Coated

Shafts Diameter=ф80/ф85mm ,precision machined

Gear/Sprocket driving,about 18-phase to sort

Primary Motor(Servo motor) =7.5KW, Frequency velocity manage

Chain size: one inch with 18teeth

All the screw bolts with quality 8.eight

True forming pace 20m/min

Po EPT EPT Chopping Device

Post to cut, cease to reducing,Two parts type of chopping blade layout, no blanking

EPT motor: 4KW

Reducing resource content: Cr12MoV,Heat remedy to HRC58-62 degree

The cutting electrical power is presented by the principal engine hydraulic station

PLC Handle Program

Management The Quantity And Cutting Length Automatically

Input The Creation Data(Production Batch,pcs,Length,etc.)On The Contact Screen ,

It Can Complete The Creation Automatically.

Blended With: PLC, Inverter, Contact Monitor, Encoder, etc

PLC:Siemens (German brand)/Schneider(Franch brand)

Inverter:Siemens (German brand)/Schneider (Franch brand)

7-Inch Colour Contact Display screen:Siemens (German brand name)/Schneider (Franch brand)

Encoder: Omron (Japan brand name)

Swap Base, Show Mild, Power Supply, Intermediate Relay, AC Contactor,

Thermal Relay: Siemens (German brand name)/Schneider (Franch brand)

Air Swap: LG-LS(Korea brand name)

Minimize-to-Size Tolerance≤±1 mm

Handle Voltage 24V

Right after-Sale Services

one. The warranty is 24 months after the client receives the machine.

Within the 24 months, we will courier the replacement parts to the client free of charge

two. We offer technical support for the entire life of our machines

three. We can send our technicians to install and train the workers in the clients’ factories with

extra cost

Conditions Of Trade

one.Minimum order quantity (MOQ): 1 Set

two.Delivery time: about 45 workdays

three.Port of loading: port of HangZhou

four.Type of payment: by T/T or by L/C

five.Export:to much more than sixty nations and locations, such as ZheJiang , United kingdom, France, Singapore,

Greece, Australia, USA, Mexico, Brazil, Chile, Xihu (We EPT Lake) Dis.via, Trinidad, Israel, Saudi Arabia, and many others

Packing Design

Packing method: Main physique of machine is bare and coated by plastic movie(to protect of du EPT and corrosion),

loaded into container and steadily fixed in container suitable by steel rope and lock, suitable for long-distance transportation.

Creating time: about 45 workdays after obtained the advance payment

Packing approach: with nude packing steadily fixed in a single 40 toes container suited for

lengthy-length transportation

ABO EPT BMS

Manufacturing unit

EXHIBITION

CERTIFICATION

Consumer

QUALITY IS OUR Tradition!

IF U ARE Fascinated OUR MACHINES

PLEASE Speak to WITH ME!

The use of first tools manufacturer’s (OEM) component figures or trademarks , e.g. CASE® and John Deere® are for reference purposes only and for indicating product use and compatibility. Our company and the shown replacement components contained herein are not sponsored, authorized, or created by the OEM.

Automatic made in China – replacement parts – roller blind chain holder nz in Taibei China, Taiwan Province of China Tissue Box Thermal Shrink Packaging Machine with ce certificate top quality low price

We – EPG Team the greatest Chain and agricultural gearbox manufacturing unit in China with 5 various branches. For much more specifics: Cell/whatsapp/telegram/Kakao us at: 0086-13083988828

EPG will often adhere to it business spirit of being practical, revolutionary, successful and superb to make the best global transmission push.ISO EPG is one particular of the greatest makers in China. We have sophisticated devices for manufacturing and new engineering tests capacity . By way of adopting new technologies from British, German, U.S.A, our items are very best sellers all more than European, America, and Southeast Asia.9001:2000 & AS 9100B licensed customized company of roller chains. Specs of roller chains contain .1475 in. to .3750 in. pitch, 5.9 in. to 35.4 in. size, one hundred eighty lbs. to 1529 lbs. tensile load ability & .035 lbs. to .276 lbs. bodyweight/ft. ISO 9001:2000 licensed. Stocking distributor of electricity transmission goods like roller & a number of strand roller chains. Items also include brakes, generate parts, gears, torque limiters, U-joints, pulleys, sheaves, encoders, belt drives, clutches & motors are also offered. Description:

Gorgeous machine, Steady quality, Basic safety,power saving, patented goods, domestic initiative, application to the POF PVC PP film thermal shrink packaging effect is best.

Characteristics:

1.Physical appearance and knot layout in accordance with nationwide stHangZhourds, the fuselage utilizes fingerprint resistant sheet generation soon after spray treatment.

2.Management panel employing programming system, 12V DC input , button swap , digital exhibit.

3. Transmission employing 24v DC Motor speed control using variable frequency technologies -9 file adjustment.

four.The conveyor belt can be employed wire mesh belt, chain roller, Teflon mesh belt a few.

5.Heating employing 600W 220V much infrared quartz heating tube.

six.Temperature control utilizing higher precision intelligent temperature management system . up and down temperature impartial regulation.

7.Hot air circulation utilizing 220V 60W 2200 to the long axis motor with wind wheel.

8.The bracket can be disassembled , and the top of the bracket can be adjusted.

| L SEALER | FQL 450 A | SHRINK TUNNEL | BSN 4571C |

| VOLTAGE | 220/50-60HZ | VOLTAGE | 380v 50-60HZ |

| Electricity | one.35KW | Power | 9KW |

| AIR Strain: | 5-7 | TUNNEL Measurement(L*W*H) | 1200*400x200mm |

| Ability | 15-30bags/min | Merchandise Dimension(W*H) | 350x150mm |

| Solution MAX SIZE L+H(H<150mm) | <500mm | EPT Speed | -15m/min |

| Item MAX Dimensions W+H(H<150mm) | < 400mm | Materials | CHAIN, TEFLON |

| SEALING Size | 550*450mm | CONVEYING LOAD | 20kg max |

| Equipment Dimension (L*W*H) | 1650*800*1450mm | Device Dimensions (L*W*H) | 1600x560x660mm |

| Excess weight | 300KG | Weight | 80kg |

| Software: | POF.PE, | Application: | PE.POF |

The use of original tools manufacturer’s (OEM) part numbers or emblems , e.g. CASE® and John Deere® are for reference needs only and for indicating solution use and compatibility. Our organization and the outlined alternative areas contained herein are not sponsored, accredited, or manufactured by the OEM.

Flexible made in China – replacement parts – stationary roller chain breaker in Abuja Nigeria Plastic Hydraulic Hose Cable Carrier Roller Conveyor CNC Machine Part Drag Chain with ce certificate top quality low price

We – EPG Team the biggest Chain and agricultural gearbox manufacturing unit in China with 5 diverse branches. For far more details: Cellular/whatsapp/telegram/Kakao us at: 0086-13083988828

We offer OEM support. EPG We will offer very best companies and high quality goods with all sincerity. a specialised supplier of a total variety of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….major maker and supplier of ball bearings and electricity transmission products. Since it is beginning in 1992, EPG has developed into a single of the leading suppliers in the business. Crucial aspects that have contributed to our progress is our commitment to the fundamentals of innovative design, competitive pricing, extraordinary buyer services, and solution availability. Common strands have an even quantity of pitches, pin links, and roller back links. A roller chain strand can be shortened by getting rid of links and lengthened by incorporating complete or a fifty percent links (offset back links). Item Description

| Product’s name | Plastic Cable Chain Wire Drag Chain for Engraving Device |

| Material | Nylon Plastic PA66 |

| Temperature | 40C-130C |

| Color | Can personalized |

Material:engineering polyamide is utilised in the manufacturing. It is affect resistant with higher power and mild in weight. It is ideal for swift movements. The sturdy composition tends to make it not liable to distort.

Application: employed in these kinds of fields as chemical industry,equipment, electric electricity and transportation vessels. Various inner widths can be used for your use.

Merchandise Display

Packing & delivery

About us

FAQ

Are you investing organization or producer ?

A: We are factory.

How prolonged is your shipping and delivery time?

Usually it is 5-ten days if the goods are in stock. or it is fifteen-20 days if the products are not in inventory, it is in accordance to quantity.

Do you give samples ? is it free or extra ?

Yes, we could offer you the sample for free of charge cost but do not spend the co EPT of freight.

What is your phrases of payment ?

Payment=1000USD, thirty% T/T in advance ,harmony ahead of cargo.

If you have an EPT issue, please feel totally free to contact us.

The use of unique products manufacturer’s (OEM) portion figures or emblems , e.g. CASE® and John Deere® are for reference reasons only and for indicating merchandise use and compatibility. Our company and the listed substitution areas contained herein are not sponsored, approved, or made by the OEM.

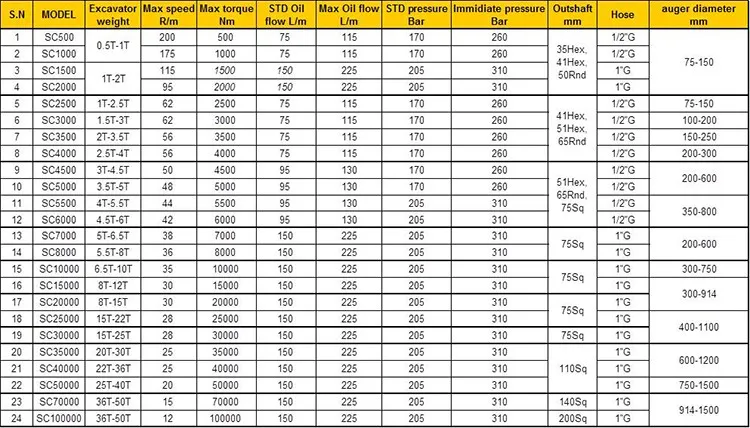

High qualtiy best price hydraulic auger drill drive for mini piling machine Torque by excavator supplier factory manufacturer & exporter in China

Overview

Quick Details

Condition: :

New

Warranty: :

1.5 years

Applicable Industries: :

Manufacturing Plant, OEM

There is a technical center of province level, EPG academician working station, experiment station for EPG post doctors, and national 863 program set up in EPG group. With these platforms and strong technical ability, the more than 400 technicians have developed all variety of special high precise and high strength products, conducted mold programs for key components in the car and national industry revitalizing program, resulting more than 5000 developed over, among which 33 items are autonomous patent technology with 4 patent approved . After Warranty Service: :

Online support

Local Service Location: :

none, United States

Showroom Location: :

none

Type: :

Bearing

Use: :

Cultivators

Place of Origin:Zhejiang, China Brand Name: :

OEM

condition: :

new

Suitable: :

1-50 ton excavator,crane ,skid steer loader

auThe high precise CNC equipment, such as Slow-feeding wire-cut machine, jig grinding machine and electric discharge machine, ensures the top quality precision of mould processing, with the high efficient and environmental protection acid rolling line being the largest raw material converting equipment in the field in china; The wildly use of automatic milling machine, high-speed automatic feeding punch, high speed automatic rolling One aspect of our application consulting is that we have been collecting and combining the experience in chain and sprocket applications in various areas for decades. This is particularly interesting for us whenever customers approach us with some exceeding and challenging requirements.and assembling machine guarantees the high quality and efficiency of components and chain making. ger diameter: :

75-1500mm

Depth: :

20M

STD oil flow: :

75L/M

STD pressure: :

170 bar

outshaft: :

41/51HEX, 65 Rnd,75Squ

Color: :

blue or black

Item: :

drill dirt auger bit

Supply Ability

Supply Ability: : 1000 Set/Sets per Month

Packaging & Delivery

Packaging Details: BOX Port: QINGDAO,DALIAN, SHANGHAI, NINGBO

Online Customization

hydraulic auger drill drive for mini piling machine Torque by excavator

Product Description

Earth Drills are renowned throughout the world for being the best augur system available. A large range of models are available to suit any machine and hole boring task from the smallest fencing job through to major piling works. With a revolutionary gearbox and non-dislodgement shaft, the EPG Earth Drill is built to out-perform and outlast, turning your machine into a truly universal piece of equipment.

Why we choose this earth auger?

It is obviously that earth auger is more efficient than manual work. Besides, using our product is safer than manual work. The hole which dig by the earth auger is more beautiful than man did.

Features & Benefits

– Non-dislodgment shaft.

– Epicyclic Gearbox

– Hose & Coupler options

– High quality hydraulic motor

– Forged hood ears

– Shock-lock tooth locking system

– Augers from 75mm to 1200mm

– new earth drills

Specification

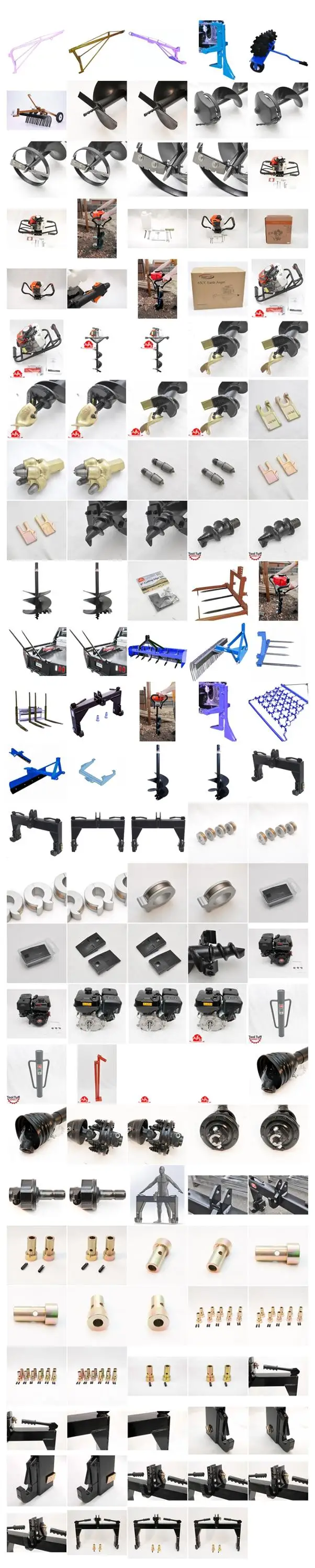

Auger Drive

1.Forged hoods ears: Deal with the heavy strain of daily use. Contact surface wider and safer.

2.American Motor: Developing the most reliable wear parts.

3.ERICYLIC gearbox: Unique planetary gearbox. Multiplied output torque. Extreme efficiency.

4.NON-dislodgement shaft: Assembled top down locked into earth drill house. Never fall out. Provided a safer environment.

5.18 Month After-sales service for auger drive.

drill dirt auger bit Soil Auger Drill Bit Earth Soil Auger Drill Machine

How to choose the most suitable type?

Related spare parts

Our auger teeth have patented unique design.Different teeth for different earth condition.

With those, I believe it is no problem to dig your dream hole.

more auger photos

Factory & Packaging

FAQ

Q: HOW CAN I CHOOSE THE SUITABLE EARTH DRILL?

A:PLEASE REFER TO BELOW QUESTIONS:

- 1. Brand and model of Excavator/Backhoe/Skid Steer loader?

- 2. Diameter of hole to be drilled?

- 3. Depth of hole to be drilled?

- 4. Ground type to be drilled?

Once you have answered the above you can easily make the correct choice.

Q: DO I NEED TO PURCHASE SPARE PARTS WHEN ORDERING AN EARTH DRILL?

A: It is not necessary to purchase spare parts for the Planetary Drive as this is a sealed unit, however it is important to follow the service schedule as outlined in the operators manual. It is advisable to purchase spare wearing parts (teeth and Pilots).

Q: CAN THE EARTH DRILL FIT A VARIETY OF MACHINES?

A: Yes, as long as the carrier’s specifications agree with the parameters of the Earth Drill as outlined in our catalogue.

Q: HOW DO I FIT THE EARTH DRILL TO MY MACHINE?

A: There are four types of mounting linkage available;

- Double Pin Hitch: to be used with excavators fitted with quick couplers.

- Double Pin Cradle hitch: also to be used with excavators fitted with quick hitch, in addition the Cradle hitch can be used to stabilise the Earth Drill whilst travelling around the site and also to aid in the clearing of spoil from the auger.

Q: WHAT CAN I DRILL?

A: There are 3 types of cutting teeth available,

1.Earth and Clay Teeth: Suitable for drilling earth and clay.

2.Tungsten Teeth: Suitable for drilling hard and abrasive ground.

3.Rock Teeth: Suitable for drilling soft, fractured, rock.

Q: HOW DEEP CAN I DRILL?

A: There are extensions available for every Earth Drill however maximum drilling depth depend on the following conditions;

- Diameter of hole to be drilled

- Depth of hole to be drilled

- Type of parent machine to be used

- Ground type to be drilled

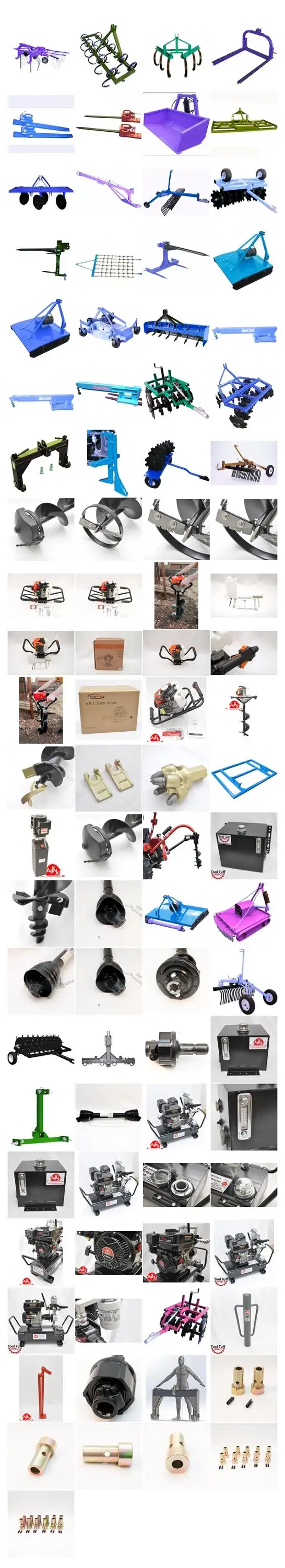

Other attachments

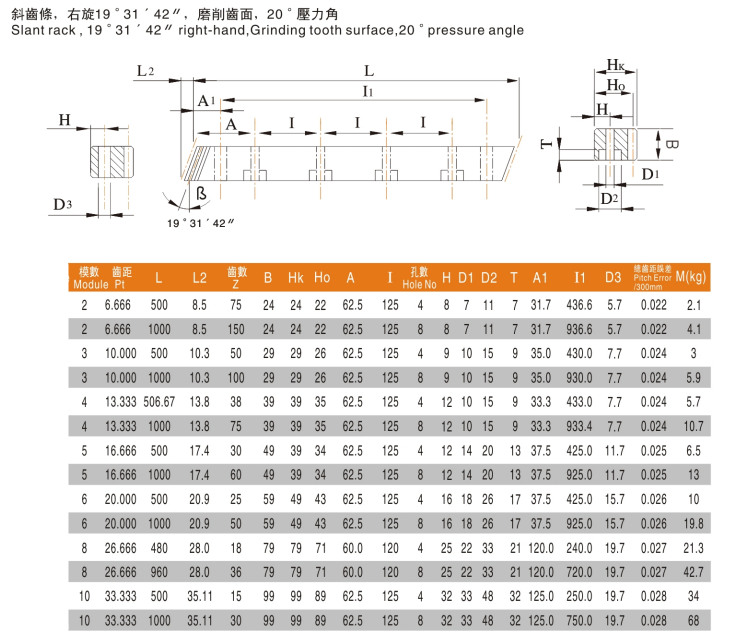

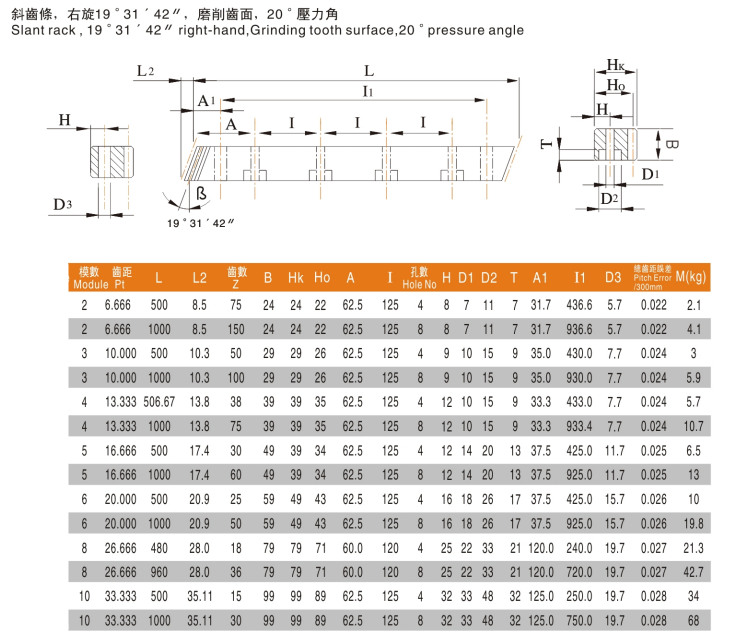

Best China manufacturer & factory China manufacturer High precision Din6 Laser cutting machine helical gear rack With high quality best price

our products are selling well in the American, European, South American and Asian markets. a specialized supplier of a full range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

- Applicable Industries:

-

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, farms, Construction works , Energy & Mining, agricultural machiner

- Product name:

-

Helical Gear Rack

- Color:

-

Nature Color

- Application:

-

Industry Machinery

- Precision grade:

-

Din6

- Surface treatment:

-

ground

- Hardness:

-

40-50 Degree HRC

- Standard:

-

standard

- Right hand angle:

-

19°31’42”

- Pressure:

-

20 Degree

- Sides ground:

-

Included

Supply Ability

- Supply Ability:

- 10000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- wooden/ carton

- Port

- TIANJIN PORT

-

Lead Time

: -

Quantity(Bags) 1 – 2 3 – 100 >100 Est. Time(days) 3 10 To be negotiated

Online Customization

EPG – one of the biggest transmisison suppliers in China. Every process, every section, every function in EPG is demanded to be done one step following another, carefully and cautiously, from material selection, reformation to manufacturing accessories, from components heat treatment to automatic assembly, from quality control to product inspection and testing and from order dealing to after sales service.”We are always serving our customers with our best products.” EPG will always adhere to it enterprise spirit of being practical, innovative, efficient and excellent to make the top international transmission drive.

Product Description

specification

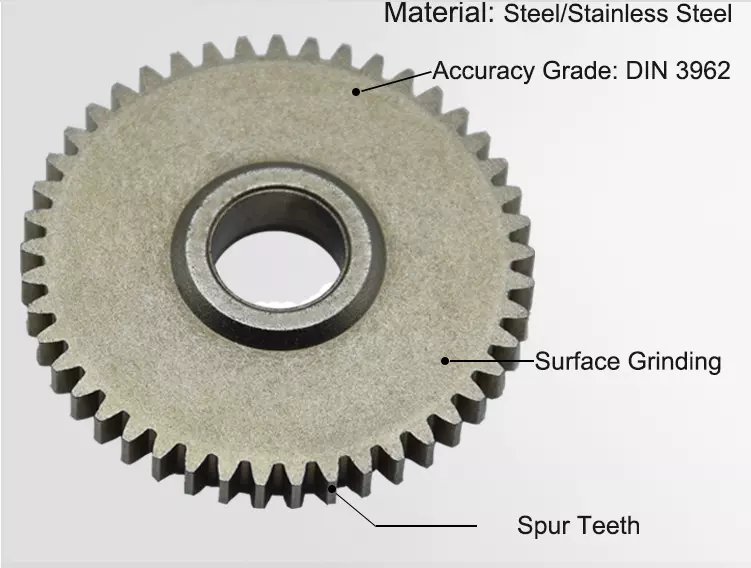

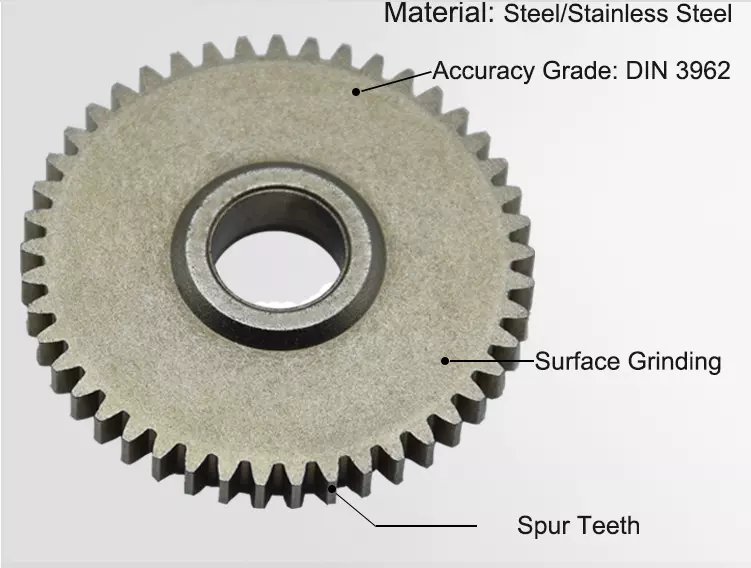

Apply to gear

Close up of shear pin which will shear in half if the implement is subject to sufficient resistance Shear pin: the shear pin shaft I use for the chipper/shredder. The driven end yoke is actually two pieces with a shear pin or bolt that holds the two pieces as one during operation. Should the equipment encounter a sudden stop the pin will take the shock and “shear off” preventing any driveline damage.

|

product name |

helical gear |

|

brand |

HRSY |

|

teeth profile |

helical |

|

precision |

DIN6 |

|

left hand angle |

19°31’42’’ |

|

treatment of teeth OUR HIGH-END SEGMENT: FINDING THE BEST SOLUTION FOR THE CUSTOMER The high-end segment often requires customized solutions. In these cases, we provide you with in-depth consulting in order to devise a common solution to meet your requirements. Only then do we get down to the actual work. |

grinding |

Gear rack catalogue

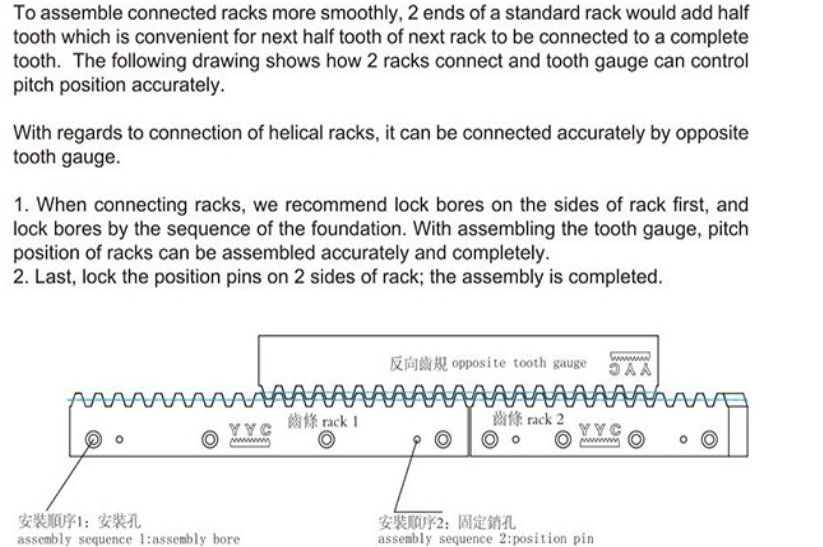

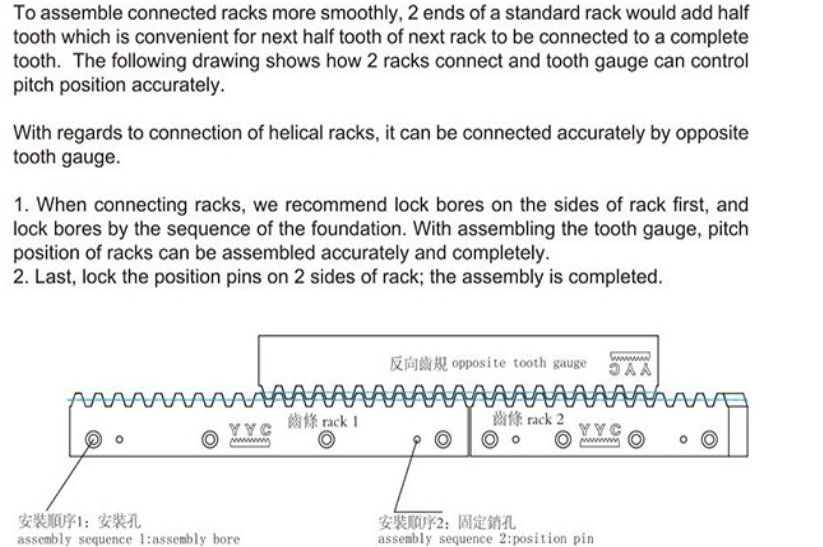

How to install gear rack

Application

Packing & Delivery

Payment & Shipping

Main product

Company introduce&photo

HangZhou EGP Electrical Equipment Co.,Ltd was founded in HangZhou in 1997 and is a professional manufacturer and exporter that is concerned with the design, development and production.With detailed requirments, we can also develop your special designed product. Our product range includes all kinds of helical gear, spur gear, bevel gear, gear rack, worm gear, sprockets,chains, bearings.Keeping in mind that good service is the key to cooperating with clients, we strive to meet high quality standards, offer competitive prices and ensure prompt Our products are selling well in Chinese markets and some products sold in international markets are well received by Chinese and foreign clients at home and abroad.delivery. In this way, our products have continued to gain market acceptance and customers satisfaction over the past few years. We are aiming to meet the demands of the clients around the world..If you are interested in any of our products or would like to discuss a potential order, please feel free to contact us. We are looking forward to developing successful business relationships with new clients around the world in the future.