Product Description

Product Description

Coupling Deatails

Name: High precision plum blossom

coupling Model: LM-Material: Aviation Aluminum Alloy

Working temperature: -40 ° C ~ 100 ° C

Support customization: Factory direct sales support customization.

Features:

1.Intermediate Elastomer Connection-Absorbs vibration, compensates for radial, angular, and axial 2.misalignment

3.Oil resistance and electrical insulation

4.Clockwise and counterclockwise rotation characteristics are identical-there are 3 different hardness 5.elastomer

6.Fixation by clamping screw.

|

Model parameter |

ΦD |

L |

LF |

LP |

F |

M |

Tightening screw torque |

|

(N.M) |

|||||||

|

GF-14X22 |

14 |

22 |

14.3 |

6.6 |

3.8 |

M 3 |

0.7 |

|

GF-20X25 |

20 |

25 |

16.7 |

8.6 |

4 |

M 3 |

0.7 |

|

GF-20X30 |

20 |

30 |

19.25 |

8.6 |

5.3 |

M 4 |

1.7 |

|

GF-25X30 |

25 |

30 |

20.82 |

11.6 |

5.6 |

M 4 |

1.7 |

|

GF-25X34 |

25 |

34 |

22.82 |

11.6 |

5.6 |

M 4 |

1.7 |

|

GF-30X35 |

30 |

35 |

23 |

11.5 |

5.75 |

M 4 |

1.7 |

|

GF-30X40 |

30 |

40 |

25.6 |

11.5 |

10 |

M 4 |

1.7 |

|

GF-40X50 |

40 |

50 |

32.1 |

14.5 |

10 |

M 5 |

4 |

|

GF-40X55 |

40 |

55 |

34.5 |

14.5 |

10 |

M 5 |

4 |

|

GF-40X66 |

40 |

66 |

40 |

14.5 |

12.75 |

M 5 |

4 |

|

GF-55X49 |

55 |

49 |

32 |

16.1 |

13.5 |

M 6 |

8.4 |

|

GF-55X78 |

55 |

78 |

46.4 |

16.1 |

15.5 |

M 6 |

8.4 |

|

GF-65X80 |

65 |

80 |

48.5 |

17.3 |

18.1 |

M 8 |

10.5 |

|

GF-65X90 |

65 |

90 |

53.5 |

17.3 |

18.1 |

M 8 |

10.5 |

Product Parameters

Detailed Photos

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can flexible couplings be used in servo motor and stepper motor applications?

Yes, flexible couplings are commonly used in both servo motor and stepper motor applications. They play a crucial role in connecting the motor shaft to the driven load while compensating for misalignments and providing other essential benefits:

- Servo Motor Applications: Servo motors require precise motion control and high responsiveness. Flexible couplings are well-suited for servo motor applications because they offer the following advantages:

- Misalignment Compensation: Servo motors are sensitive to misalignments, which can lead to decreased performance and increased wear. Flexible couplings can accommodate angular, parallel, and axial misalignments, ensuring that the motor and driven load remain properly aligned during operation.

- Vibration Damping: Flexible couplings help reduce vibrations, which is crucial for servo motor applications that require smooth and precise motion. By absorbing and dissipating vibrations, flexible couplings contribute to the overall stability and accuracy of the system.

- Backlash Minimization: Some flexible couplings have minimal to no backlash, making them suitable for high-precision servo motor applications where any play or clearance between components could affect performance.

- High Torque Capacity: Servo motors often require high torque transmission capabilities. Flexible couplings are available in various designs and materials, allowing for the selection of couplings with appropriate torque ratings for specific servo motor applications.

- Stepper Motor Applications: Stepper motors are commonly used in open-loop control systems where precise positioning is necessary. Flexible couplings are used in stepper motor applications due to the following reasons:

- Misalignment Tolerance: Stepper motors can experience misalignments, especially in dynamic applications. Flexible couplings can handle misalignments without introducing significant backlash or affecting the stepper motor’s accuracy.

- Cost-Effectiveness: Flexible couplings are often more cost-effective than other types of couplings, making them a practical choice for stepper motor applications, especially in cases where precision requirements are not as stringent as in servo motor systems.

- Shock Load Absorption: Some stepper motor applications involve abrupt starts and stops, leading to shock loads. Flexible couplings can absorb these shocks and protect the motor and driven load from damage.

- Simplicity: Flexible couplings are simple in design and easy to install, making them a popular choice in various stepper motor applications.

Overall, flexible couplings offer valuable benefits in both servo motor and stepper motor applications. They help improve system performance, reduce wear on components, and enhance the overall reliability of the motion control systems they are employed in.

What are the key considerations for selecting a flexible coupling for high-speed applications?

When selecting a flexible coupling for high-speed applications, several critical considerations should be taken into account to ensure optimal performance and reliability:

- Material and Design: Choose a flexible coupling made from high-quality materials that can withstand the high rotational speeds without experiencing excessive wear or fatigue. Consider designs that are specifically engineered for high-speed applications, ensuring they have the required torsional stiffness and damping characteristics.

- Balance: Imbalance at high speeds can lead to vibration and reduce the lifespan of the coupling and connected components. Look for precision-balanced flexible couplings that minimize vibration and avoid any potential resonance issues at operating speeds.

- Torsional Stiffness: In high-speed applications, torsional stiffness is crucial to maintaining accurate rotational timing and preventing torque losses. Choose a flexible coupling with adequate torsional stiffness to minimize angular deflection under load.

- Dynamic Balancing: Dynamic balancing is essential for flexible couplings used in high-speed applications. A dynamically balanced coupling reduces vibrations caused by rotational imbalances, increasing the smoothness and stability of the system.

- Temperature Resistance: High-speed operations can generate significant heat, so select a flexible coupling that can withstand the elevated temperatures without compromising its mechanical properties or causing premature failure.

- Alignment and Runout Tolerance: Accurate alignment of the coupling with the shafts is crucial to prevent additional stress and vibration. Consider couplings with high runout tolerance and ease of alignment to facilitate proper installation.

- Service Life and Maintenance: Evaluate the expected service life of the flexible coupling in high-speed applications. Low-maintenance couplings are desirable to reduce downtime and maintenance costs.

- Application Specifics: Consider the specific requirements of the high-speed application, such as the magnitude of torque, axial movement, and the presence of shock loads. Choose a coupling that can handle these specific demands while maintaining performance at high speeds.

- Compliance with Standards: Ensure that the selected flexible coupling complies with relevant industry standards and specifications, especially those related to high-speed performance and safety.

By carefully considering these key factors, engineers can choose a flexible coupling that meets the demands of high-speed applications, delivering reliable and efficient power transmission while minimizing the risk of premature wear, vibration, and downtime.

What are the maintenance requirements for flexible couplings?

Maintenance of flexible couplings is essential to ensure their reliable and efficient performance over their service life. Proper maintenance helps prevent premature wear, reduces the risk of unexpected failures, and extends the lifespan of the couplings. Here are some key maintenance requirements for flexible couplings:

- Regular Inspection: Perform regular visual inspections of the flexible couplings to check for signs of wear, damage, or misalignment. Look for cracks, tears, or any other visible issues in the coupling components.

- Lubrication: Some flexible couplings, especially those with moving parts or sliding surfaces, may require periodic lubrication. Follow the manufacturer’s recommendations regarding the type and frequency of lubrication to ensure smooth operation.

- Alignment Checks: Misalignment is a common cause of coupling failure. Regularly check the alignment of the connected shafts and adjust as necessary. Proper alignment reduces stress on the coupling and improves power transmission efficiency.

- Torque Monitoring: Monitoring the torque transmitted through the coupling can help detect any abnormal or excessive loads. If the coupling is subjected to loads beyond its rated capacity, it may lead to premature failure.

- Environmental Protection: If the couplings are exposed to harsh environmental conditions, take measures to protect them from dust, dirt, moisture, and corrosive substances. Consider using protective covers or seals to shield the couplings from potential contaminants.

- Temperature Considerations: Ensure that the operating temperature of the flexible coupling is within its designed range. Excessive heat can accelerate wear, while extremely low temperatures may affect the flexibility of certain coupling materials.

- Replace Worn or Damaged Parts: If any components of the flexible coupling show signs of wear or damage, replace them promptly with genuine replacement parts from the manufacturer.

- Manufacturer’s Guidelines: Follow the maintenance guidelines provided by the coupling manufacturer. They often include specific maintenance intervals and procedures tailored to the coupling’s design and materials.

- Training and Expertise: Ensure that maintenance personnel have the necessary training and expertise to inspect and maintain the flexible couplings properly. Improper maintenance practices can lead to further issues and compromise the coupling’s performance.

By adhering to these maintenance requirements, you can maximize the service life of the flexible couplings and minimize the risk of unexpected downtime or costly repairs. Regular maintenance helps maintain the efficiency and reliability of the coupling in various industrial, automotive, and machinery applications.

editor by CX 2024-04-19

China factory CNC Aluminum Elastic Rubber Spider Jaw Shaft Coupler GF14*22 20*25 25*30 40*50 Shaft Flexible Coupling Ball Screw Plum Coupling

Product Description

Product Description

Coupling Deatails

Name: High precision plum blossom

coupling Model: LM-Material: Aviation Aluminum Alloy

Working temperature: -40 ° C ~ 100 ° C

Support customization: Factory direct sales support customization.

Features:

1.Intermediate Elastomer Connection-Absorbs vibration, compensates for radial, angular, and axial 2.misalignment

3.Oil resistance and electrical insulation

4.Clockwise and counterclockwise rotation characteristics are identical-there are 3 different hardness 5.elastomer

6.Fixation by clamping screw.

|

Model parameter |

ΦD |

L |

LF |

LP |

F |

M |

Tightening screw torque |

|

(N.M) |

|||||||

|

GF-14X22 |

14 |

22 |

14.3 |

6.6 |

3.8 |

M 3 |

0.7 |

|

GF-20X25 |

20 |

25 |

16.7 |

8.6 |

4 |

M 3 |

0.7 |

|

GF-20X30 |

20 |

30 |

19.25 |

8.6 |

5.3 |

M 4 |

1.7 |

|

GF-25X30 |

25 |

30 |

20.82 |

11.6 |

5.6 |

M 4 |

1.7 |

|

GF-25X34 |

25 |

34 |

22.82 |

11.6 |

5.6 |

M 4 |

1.7 |

|

GF-30X35 |

30 |

35 |

23 |

11.5 |

5.75 |

M 4 |

1.7 |

|

GF-30X40 |

30 |

40 |

25.6 |

11.5 |

10 |

M 4 |

1.7 |

|

GF-40X50 |

40 |

50 |

32.1 |

14.5 |

10 |

M 5 |

4 |

|

GF-40X55 |

40 |

55 |

34.5 |

14.5 |

10 |

M 5 |

4 |

|

GF-40X66 |

40 |

66 |

40 |

14.5 |

12.75 |

M 5 |

4 |

|

GF-55X49 |

55 |

49 |

32 |

16.1 |

13.5 |

M 6 |

8.4 |

|

GF-55X78 |

55 |

78 |

46.4 |

16.1 |

15.5 |

M 6 |

8.4 |

|

GF-65X80 |

65 |

80 |

48.5 |

17.3 |

18.1 |

M 8 |

10.5 |

|

GF-65X90 |

65 |

90 |

53.5 |

17.3 |

18.1 |

M 8 |

10.5 |

Product Parameters

Detailed Photos

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

How do flexible couplings handle axial movement in rotating machinery?

Flexible couplings are designed to handle different types of misalignments in rotating machinery, including axial movement or axial misalignment. Axial movement occurs when there is displacement along the axis of rotation, causing one shaft to move closer to or away from the other shaft. Here’s how flexible couplings handle axial movement:

- Sliding Capability: Many flexible couplings, especially those with elastomeric elements or certain designs, can slide along the shafts they connect. This sliding capability allows the coupling to accommodate axial movement without introducing additional stress on the connected components. The elastomeric elements can compress or stretch slightly to absorb the axial displacement.

- Multiple-piece Designs: Some flexible couplings consist of multiple pieces, which allow for axial movement. These designs often have a floating member or a spacer that separates the two shaft-connected components. The floating member can move axially as needed, while still transmitting torque and compensating for other misalignments.

- Double-Cardanic Design: Certain high-performance flexible couplings use a double-cardanic design, allowing for misalignment in multiple directions, including axial movement. This design features two sets of flexible elements that work together to accommodate different misalignments and provide a high degree of flexibility.

It’s important to note that while flexible couplings can handle a certain degree of axial movement, excessive axial misalignment might require a different type of coupling or additional measures to be addressed properly.

During the selection and installation process, it’s essential to consider the application’s axial movement requirements and choose a flexible coupling that can accommodate the expected axial displacement while still providing the desired performance, such as vibration damping, shock absorption, or precision motion control.

How does a flexible coupling accommodate changes in shaft alignment due to thermal expansion?

Flexible couplings are designed to accommodate changes in shaft alignment that occur due to thermal expansion in rotating machinery. When equipment operates at elevated temperatures, the materials used in the shafts and other components expand, causing shifts in the relative positions of the connected shafts. This thermal expansion can lead to misalignment, which, if not addressed, may result in additional stress on the equipment and premature wear.

Flexible couplings employ specific design features that allow them to handle thermal-induced misalignment effectively:

- Flexibility: The primary feature of a flexible coupling is its ability to flex and deform to some extent. This flexibility allows the coupling to absorb small amounts of angular, parallel, and axial misalignment that may result from thermal expansion. As the shafts expand or contract, the flexible coupling compensates for the misalignment, helping to maintain proper alignment between the two shafts.

- Radial Clearance: Some flexible couplings, such as elastomeric couplings, have radial clearance between the coupling’s mating parts. This radial clearance provides additional room for the shafts to move laterally during thermal expansion without creating excessive forces on the coupling or connected equipment.

- Sliding Elements: Certain flexible couplings feature sliding elements that can move relative to each other. This capability allows the coupling to accommodate axial displacement resulting from thermal expansion or other factors.

- Flexible Element Materials: The materials used in the flexible elements of the coupling are chosen for their ability to handle the temperature range experienced in the application. Elastomeric materials, for example, can be selected to withstand high temperatures while still maintaining their flexibility.

It is essential to understand that while flexible couplings can compensate for some degree of thermal-induced misalignment, there are limits to their capabilities. If the thermal expansion exceeds the coupling’s compensating range, additional measures, such as incorporating expansion joints or using specialized couplings designed for greater misalignment compensation, may be necessary.

When selecting a flexible coupling for an application with potential thermal expansion, it is crucial to consider the expected operating temperature range and the level of misalignment that may occur due to thermal effects. Working with coupling manufacturers and consulting coupling catalogs can help in choosing the most suitable coupling type and size for the specific thermal conditions of the machinery.

How does a flexible coupling protect connected equipment from shock loads and vibrations?

Flexible couplings play a crucial role in protecting connected equipment from shock loads and vibrations by providing damping and isolation capabilities. When machines or mechanical systems experience sudden shock loads or vibrations, the flexible coupling acts as a buffer, absorbing and dissipating the impact, thereby reducing the transmitted forces and protecting the equipment. Here’s how flexible couplings achieve this:

- Damping of Vibrations: Flexible couplings are often made from materials that exhibit damping properties. When vibrations are transmitted through the shafts, the flexible coupling’s material can absorb a portion of the vibrational energy, converting it into heat. This dissipation of energy helps reduce the amplitude of the vibrations and prevents them from propagating further into the connected equipment.

- Vibration Isolation: In addition to damping vibrations, flexible couplings also offer a degree of vibration isolation. They are designed to decouple the two shafts, which means that vibrations occurring on one shaft are not directly transmitted to the other shaft. This isolation effect prevents vibrations from propagating across the entire system and minimizes the impact on sensitive equipment or nearby components.

- Shock Absorption: When the connected machinery experiences sudden shock loads, such as during a startup or abrupt changes in load, the flexible coupling can act as a shock absorber. The coupling’s design allows it to deform slightly under the impact, absorbing and distributing the shock energy. This prevents the shock from being directly transferred to the connected equipment, reducing the risk of damage or premature wear.

- Misalignment Compensation: Flexible couplings are capable of compensating for misalignment between the shafts. Misalignment can lead to additional stresses and vibrations in the system. By allowing for some degree of angular, parallel, and axial misalignment, the flexible coupling reduces the forces transmitted to the connected equipment and the supporting structures.

- Reduction of Resonance Effects: Resonance is a phenomenon that occurs when the natural frequency of a system matches the frequency of external vibrations, leading to amplified vibrations. Flexible couplings can help avoid resonance effects by altering the system’s natural frequency and providing some level of flexibility that damps the resonance response.

By incorporating a flexible coupling into the drivetrain or power transmission system, equipment manufacturers and operators can significantly improve the reliability and longevity of connected machinery. The coupling’s ability to dampen vibrations, isolate shocks, and compensate for misalignment contributes to a smoother and more stable operation, reducing maintenance requirements and enhancing overall system performance.

In summary, flexible couplings act as protective elements, shielding connected equipment from shock loads and vibrations. Their ability to dampen vibrations, isolate shocks, and compensate for misalignment contributes to a smoother and more reliable operation of various mechanical systems.

editor by CX 2024-04-08

China high quality CNC Aluminum Elastic Rubber Spider Jaw Shaft Coupler GF14*22 20*25 25*30 40*50 Shaft Flexible Coupling Ball Screw Plum Coupling

Product Description

Product Description

Coupling Deatails

Name: High precision plum blossom

coupling Model: LM-Material: Aviation Aluminum Alloy

Working temperature: -40 ° C ~ 100 ° C

Support customization: Factory direct sales support customization.

Features:

1.Intermediate Elastomer Connection-Absorbs vibration, compensates for radial, angular, and axial 2.misalignment

3.Oil resistance and electrical insulation

4.Clockwise and counterclockwise rotation characteristics are identical-there are 3 different hardness 5.elastomer

6.Fixation by clamping screw.

|

Model parameter |

ΦD |

L |

LF |

LP |

F |

M |

Tightening screw torque |

|

(N.M) |

|||||||

|

GF-14X22 |

14 |

22 |

14.3 |

6.6 |

3.8 |

M 3 |

0.7 |

|

GF-20X25 |

20 |

25 |

16.7 |

8.6 |

4 |

M 3 |

0.7 |

|

GF-20X30 |

20 |

30 |

19.25 |

8.6 |

5.3 |

M 4 |

1.7 |

|

GF-25X30 |

25 |

30 |

20.82 |

11.6 |

5.6 |

M 4 |

1.7 |

|

GF-25X34 |

25 |

34 |

22.82 |

11.6 |

5.6 |

M 4 |

1.7 |

|

GF-30X35 |

30 |

35 |

23 |

11.5 |

5.75 |

M 4 |

1.7 |

|

GF-30X40 |

30 |

40 |

25.6 |

11.5 |

10 |

M 4 |

1.7 |

|

GF-40X50 |

40 |

50 |

32.1 |

14.5 |

10 |

M 5 |

4 |

|

GF-40X55 |

40 |

55 |

34.5 |

14.5 |

10 |

M 5 |

4 |

|

GF-40X66 |

40 |

66 |

40 |

14.5 |

12.75 |

M 5 |

4 |

|

GF-55X49 |

55 |

49 |

32 |

16.1 |

13.5 |

M 6 |

8.4 |

|

GF-55X78 |

55 |

78 |

46.4 |

16.1 |

15.5 |

M 6 |

8.4 |

|

GF-65X80 |

65 |

80 |

48.5 |

17.3 |

18.1 |

M 8 |

10.5 |

|

GF-65X90 |

65 |

90 |

53.5 |

17.3 |

18.1 |

M 8 |

10.5 |

Product Parameters

Detailed Photos

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

How do you install and align a flexible coupling properly to ensure optimal performance?

Proper installation and alignment of a flexible coupling are essential to ensure its optimal performance and longevity. Incorrect installation can lead to premature wear, increased vibrations, and potential equipment failure. Below are the steps to install and align a flexible coupling properly:

1. Pre-Installation Inspection:

Before installation, inspect the flexible coupling and its components for any visible damage or defects. Check that the coupling’s size and specifications match the application requirements. Ensure that the shafts and equipment connected to the coupling are clean and free from debris.

2. Shaft Preparation:

Prepare the shafts by removing any oil, grease, or contaminants from the surfaces that will come into contact with the coupling. Ensure that the shaft ends are smooth and free from burrs that could affect the fit of the coupling.

3. Coupling Hub Installation:

Slide the coupling hubs onto the shafts, ensuring they are positioned securely and evenly on each shaft. Use a lubricant recommended by the manufacturer to facilitate the installation and ensure a proper fit.

4. Alignment:

Proper alignment is critical for the performance and longevity of the flexible coupling. Align the shafts by checking both angular and parallel misalignment. Utilize precision alignment tools, such as dial indicators or laser alignment systems, to achieve accurate alignment. Follow the manufacturer’s alignment specifications and tolerance limits.

5. Tightening Fasteners:

Once the shafts are properly aligned, tighten the coupling’s fasteners to the manufacturer’s recommended torque values. Gradually tighten the fasteners in a cross pattern to ensure even distribution of the load on the coupling hubs. Avoid over-tightening, as it may cause distortion or damage to the coupling.

6. Run-Out Check:

After installation, perform a run-out check to verify that the coupling’s rotating components are balanced and aligned. Excessive run-out can lead to vibrations and reduce the coupling’s performance. If significant run-out is detected, recheck the alignment and address any issues that may be causing it.

7. Lubrication:

Ensure that the flexible coupling is adequately lubricated, following the manufacturer’s recommendations. Proper lubrication reduces friction and wear, enhancing the coupling’s efficiency and reliability.

8. Periodic Inspection and Maintenance:

Regularly inspect the flexible coupling for signs of wear, misalignment, or damage. Address any issues promptly to prevent further problems. Depending on the coupling type and application, scheduled maintenance may include re-greasing, re-alignment, or replacing worn components.

Summary:

Proper installation and alignment are crucial for ensuring the optimal performance and longevity of a flexible coupling. Following the manufacturer’s guidelines, inspecting the components, achieving accurate alignment, and using the appropriate lubrication are key steps in the installation process. Regular inspection and maintenance help to identify and address potential issues, ensuring the coupling continues to operate smoothly and efficiently in the mechanical system.

Can flexible couplings be used in power generation equipment, such as turbines and generators?

Yes, flexible couplings are commonly used in power generation equipment, including turbines and generators. These critical components of power generation systems require reliable and efficient shaft connections to transfer power from the prime mover (e.g., steam turbine, gas turbine, or internal combustion engine) to the electricity generator.

Flexible couplings play a vital role in power generation equipment for the following reasons:

- Misalignment Compensation: Power generation machinery often experiences misalignment due to factors like thermal expansion, settling, and foundation shifts. Flexible couplings can accommodate these misalignments, reducing the stress on shafts and minimizing wear on connected components.

- Vibration Dampening: Turbines and generators can generate significant vibrations during operation. Flexible couplings help dampen these vibrations, reducing the risk of resonance and excessive mechanical stress on the system.

- Torsional Shock Absorption: Power generation equipment may encounter torsional shocks during startup and shutdown processes. Flexible couplings can absorb and dissipate these shocks, protecting the entire drivetrain from damage.

- Isolation of High Torque Loads: Some power generation systems may have torque fluctuations during operation. Flexible couplings can isolate these fluctuations, preventing them from propagating to other components.

- Electrical Isolation: In certain cases, flexible couplings with non-metallic elements can provide electrical isolation, preventing the transmission of electrical currents between shafts.

Power generation applications impose specific requirements on flexible couplings, such as high torque capacity, robust construction, and resistance to environmental factors like temperature and humidity. Different types of flexible couplings, including elastomeric, metallic, and composite couplings, are available to meet the varying demands of power generation equipment.

When selecting a flexible coupling for power generation equipment, engineers must consider factors such as the type of prime mover, torque and speed requirements, operating conditions, and the specific application’s environmental challenges. Consulting with coupling manufacturers and following their engineering recommendations can help ensure the appropriate coupling is chosen for each power generation system.

Are there any limitations or disadvantages of using flexible couplings?

While flexible couplings offer numerous advantages, they do come with some limitations and disadvantages that should be considered when selecting them for specific applications. Here are some of the common limitations and disadvantages of using flexible couplings:

- Torsional Stiffness: Flexible couplings provide some level of torsional flexibility, which is advantageous in many applications. However, in systems that require high precision and minimal angular deflection, the inherent flexibility of the coupling may not be suitable. In such cases, a rigid coupling may be more appropriate.

- Limitation in High-Torque Applications: While some flexible couplings can handle moderate to high torque levels, they may not be as well-suited for extremely high-torque applications. In such cases, specialized couplings, such as gear couplings, may be required to handle the high torque demands.

- Temperature Limitations: The performance of certain flexible coupling materials, especially elastomers and plastics, may be affected by extreme temperature conditions. High temperatures can lead to premature wear and reduced lifespan of the coupling, while low temperatures may result in reduced flexibility and potential brittleness.

- Chemical Compatibility: Certain flexible coupling materials may not be compatible with certain chemicals or substances present in the application’s environment. Exposure to chemicals can cause degradation or corrosion of the coupling material, affecting its performance and lifespan.

- Installation and Alignment: Flexible couplings require proper installation and alignment to function effectively. If not installed correctly, misalignment issues may persist, leading to premature wear and reduced performance. Aligning the shafts accurately can be time-consuming and may require specialized equipment and expertise.

- Cost: In some cases, flexible couplings may be more expensive than rigid couplings due to their more complex design and use of specialized materials. However, the cost difference is often justified by the benefits they offer in terms of misalignment compensation and vibration damping.

- Service Life: The service life of a flexible coupling can vary depending on the application’s conditions and the quality of the coupling. Regular maintenance and timely replacement of worn or damaged parts are essential to ensure the coupling’s longevity and prevent unexpected failures.

Despite these limitations, flexible couplings remain highly valuable components in a wide range of applications, providing efficient torque transmission and compensating for misalignment. Proper selection, installation, and maintenance can help mitigate many of the disadvantages associated with flexible couplings, ensuring their reliable and long-lasting performance in various mechanical systems.

editor by CX 2024-03-12

Best made in China – replacement parts – Chain & sprocket manufacturer : Heavy bike chain belt in Rawalpindi Pakistan Duty Flexible Carbon Steel Stainless Steel Spiral and Screw Chain Conveyor with ce certificate top quality low price

We – EPG Group the largest Chain and agricultural gearbox manufacturing unit in China with 5 distinct branches. For more information: Cell/whatsapp/telegram/Kakao us at: 0086-13083988828

We also can layout and make non-regular goods to meet up with customers’ unique specifications. EPG We examine every piece of bearing by ourselves before shipping.electrical power transmission merchandise are designed to deliver equally reliable efficiency and price-effectiveness. Each solution is utility-tested and engineered to meet stringent expectations for uniformity in dimension, heat therapy, tensile strength and other critical characteristics. As a cost-powerful option created especially for general-obligation use, EPG’s increasing line of products are accessible in all usually requested measurements and requirements, including ball bearings, mounted models, roller chain, seals, gauges, sheaves and far more. To start with: revolutionary merchandise engineering. We are repeatedly improving nicely-proven and recognized products in the locations of generate and conveyance technologies or are seeking for feasible innovations. A single instance for this is the routine maintenance-totally free chain. Next: excellent generation engineering. Our production procedures are also continuously enhanced upon. Fairly frequently effective, new items are only feasible because of progressive creation approaches. Thirdly: capable software consulting. Specification and characteristic of the spiral conveyor:

1) Compact structure, conserving ground place

two) Cost-effective, simplify processing technologies, improving productivity

three) Effortless to set up and preserve

four) The spiral conveyor considerably less than 10m can be produced as a whole and only want one particular motor.

5) Can broadly use in beverage, foods, day-to-day commodity, pharmaceutical and logistics, etc sector

6) Operating principle: from diverse flooring vertical transport, the conveying products are mainly plastic box, carbons, cases and packed products

7) 1 motor for the spiral conveyor with regards to the ground peak distinction considerably less than 10m.

8) Uplifting or down transportation,Max load: 50Kg/m,Max pace: 60m/min,Angle:7 -15°

Layout direction for spiral conveyor:

ZheJiang EPT Foodnbev EPT forces to generate all varieties of conveyor systems depending on buyer wants.

And all types of conveyor spare areas like the modular belt, prime chain, the conveyor connection components.

Specification:

| EPT Size | one-25m, based on your task design and style |

| EPT Width | .3-3m, for smaller width, we recommend use chain conveyor |

| EPT Peak | Adjustable. Whee EPT and brake are offered |

| Frame material | Stainless steel/ Carbon steel with coating/ Aluminum |

| Belt substance | POM/PP plastic modular belt |

| EPT belts | PVC/PU/Mesh belt/ Plastic chain/Stainless chain all offered based on the goods that transfer |

| Motor | Italy brand name/SEW/China brand |

| Voltage | 380V(415V)/50HZ(60HZ) |

| Certificate of equipment | SGS/Fda |

| Certificate of unique | Form E/F/P/A/L/M |

| Price phrases | FOB/CIF |

| Company kind | Producer |

Connected pictures of the conveyor technique

Modular belt conveyor configuration checklist:

| Belt | Flat best or Flush grid modular belt, POM materials. |

| Body framework | Watertight SS 304 substance frame with SS304 bearing( decide on this type frame and bearing when the products that transfer with drinking water). Stainless steel frame widely employs in meals and beverage industry goods transfer.

Body bending without any slot at the backside. It can improve the life time of the conveyor. Filler strip with stainless metal underneath the belt to protect the modular belt runs efficiently. And assistance the belt working beneath substantial load potential with large velocity. It also can minimize the friction coefficient among the modular belt and conveyor body. |

| Support leg | Use bow shape to make the conveyor much more secure. Also can pick tripod stand |

| Electricity system | Large-quality motor with electrical control cabinet |

| Automatic manage system |

Can attain functions this kind of as lane separation, sorting, screening, classification, and many others. in accordance to your require |

| EPT design | We can fabricate according to your drawing. Also, we have a big design group that can make design and style for your according to your manufacturing unit structure. We specifically good at complete plant transportation layout |

| Delivery time | fifteen workdays |

ZheJiang EPT Manufacturing unit and Office overview

Related goods made by ZheJiang EPT Foodnbev EPT Co.,ltd

| EPT system | All kinds of the automatic conveyor method |

| Modular belt | All sorts of modular belt, FT/FG/RIB/ROLLER Leading sequence |

| Plastic chain | Plastic top chain, Versatile chain, Stainless metal chain |

| Market belt | PVC/PU belt, TPU belt, timing belt |

| EPT roller | Stainless metal roller, PVC roller |

| EPT conveyor spare parts | Guard rails, Wear strips, Foot foundation, Bearing, Relationship elements |

Business introduces:

ZheJiang H.J FoodnBev EPT Co., Ltd focuses on delivering our clients with reputable,

simple-to-use conveyor programs and relevant parts that satisfy their requirements.

With our possess manufacturing unit which located in ZheJiang , EPT products are exported to Southea EPT Asia,

South The united states, the Center East, Europe, and also popular in the domestic market.

We method each venture with the intent of discovering a better way to remedy the customers’ troubles by listening to their personal demands, and implementing what we discover to be EPT remedy their distinct content handling

demands.

We are seeking ahead to cooperating with you!

The use of original equipment manufacturer’s (OEM) portion numbers or trademarks , e.g. CASE® and John Deere® are for reference reasons only and for indicating solution use and compatibility. Our organization and the outlined replacement components contained herein are not sponsored, authorized, or made by the OEM.

Best made in China – replacement parts – pintle Chain & sprocket manufacturer : Ingersoll MR45 Chain (Agricultural Roller Chain) in Padova Italy Rand Doosan Portable Screw Compressor, Compressor, Air Compressor with ce certificate top quality low price

We – EPG Group the largest Chain and agricultural gearbox manufacturing facility in China with 5 various branches. For more specifics: Cell/whatsapp/telegram/Kakao us at: 0086-13083988828

We also can layout and make non-normal products to fulfill customers’ special requirements. Common Our main items are chain , gears, sprocket, Needle Roller bearings, Cylindrical Roller Bearings, Rod conclude Bearings, Spherical simple bearings, Observe roller Bearings for Guideway, Roller Bearings, Blend Bearings for forklifts, Drinking water Pump Bearings, SNR Automobile Bearings and all varieties of Spherical Bearings. solitary-strand roller chain, standardized by ASME, is an assembly of alternating pin links and roller backlinks. The distance among pin centers is called the pitch. The pitch is what categorizes the dimensions of the chain. The more substantial the pitch, the increased the load rating. Chains with little pitches carry smaller hundreds, function far more quietly, and at greater speeds. Multi-strand, little-pitch roller chains are a great solution for high-load, substantial-velocity programs. EPT chains, each regular and non-common, are created of: ○ Higher quality steels: proportions and adapted chemical composition for the different chain parts ○ The most effective manufacturing processes: • Unique method for the manufacturing of bushes bettering the chain wear resistance ( EPT know-how) • Plates developed by multi-phase processing instruments guaranteeing a standard pitch ( EPT technologies) ○ Ample mechanical and heat remedies of chain elements: • Shot peening • Area finishing • Scenario hardening, carbonitriding, quenching, tempering … • EPT®treatment • Freezing treatment method • Corrosion safety coatings (GEOMET, zinc, nickel plating, …) The custom of rugged trustworthiness proceeds

Ingersoll Rand 675 825 cfm compressors proceed in a course of their possess&comma leaving rivals in

The dust&period They have straightforward-to-maintain&comma single-wall coolers that guarantee substantial performance in demanding circumstances&comma large-obligation tandem-axle managing equipment for freeway towing with an distinctive prolonged-existence slipper spring technique&comma and a amazing-box style that prolongs component lifestyle although getting rid of lengthy awesome-down intervals&interval Our portable compressors are created for long-time period use and highest efficiency&period Furthermore&comma galvanneal sheet steel is stHangZhourd in substantial-corrosion areas&comma incorporating to their lasting longevity&interval Ingersoll Rand compressors have the lowe EPT overall co EPT of possession when when compared to EPT units on the market&period of time

Functionality Functions

three&sol8″ basic safety chains with quality forty three hooks

one-year &sol 2&comma 000-hour package warranty

two-12 months &sol 4&comma 000-hour guarantee airend stHangZhourd&comma extended to 5-calendar year &sol 10&comma 000-hour guarantee with use of Ingersoll Rand elements and fluids

five hundred-hour motor oil support &sol 1&comma 000-hour airend oil service

Automatic basic safety shutdowns for higher dischar ge air temperature&comma lower motor oil force&comma large engine coolant temperature&comma and low fuel stage

Backlit gauges

Straightforward routine maintenance of coolers&comma filters&comma and fluids

Gas &sol h2o separat or as primar y filtration

Heavy-obligation fourteen-gauge fenders

Heav y-obligation A-body removable drawbar with adjustable-peak pintle eye

Large&comma powerful 1&comma one hundred fifty CCA batteries

Microprocessor-managed engine with optimal compressor efficiency

Secured lifting eye with int erior launch pin

Slam latch handles with padlock pr ovisions

N StHangZhourd motor auxiliary generate provision

Selected Alternatives

Aftercooler furthermore h2o separator with 20° F approach temperature

Central dr ains for single-position fluid routine maintenance

Cold start off package consists of motor block heaters&comma engine oil pan&comma batteries

Dual force regulation&colon HP units available with a hundred &sol 150 psig&semi XP units accessible with one hundred &sol a hundred twenty five psig

Total galvanneal sheet metal

EPT surge brakes with 3-placement

Hitch &lparsubject to nearby DOT restrictions&rpar

IQ System™ Aftercooler plus particulate and coalescing filters with patented condensate disposal sy EPT em f or cleaner&comma drier air

Less operating gear includes isolation mounts for truck&comma trailer&comma or everlasting pad installation

Multiple air outlets&colon &lpar1&rpar 2″ and

&lpar3&rpar 1-1&sol4″ valves

| MODEL | HP675WCU | XP750WCU | HP750WCU | XP825WCU |

| COMPRESSOR _ ROTARY-SCREW / One-Phase | ||||

| Cost-free-air Delivery – cfm (m3/min) | 675 (19.1) | 750 (21.2) | 750 (21.2) | 825 (23.4) |

| Rated Working Strain – psig (bar) | 150 (10.3) | a hundred twenty five (8.6) | 150 (ten.3) | one hundred twenty five (8.6) |

| Motor | ||||

| Make | Cummins | Cummins | Cummins | Cummins |

| Model | QSC 8.3 | QSC 8.three | QSC 8.three | QSC 8.3 |

| Rated Velocity – rpm | two,000 | 2,000 | two,000 | two,000 |

| Bhp (kW) EPT Email [email protected] Rated Speed | 260 (194) | 260 (194) | 280 (209) | 280 (209) |

| Gas Tank Capability – gal (L) | 122 (462 | 122 (462) | 122 (462) | 122 (462) |

| Proportions | ||||

| Length – in (mm) | 195.1 (4956) | 195.1 (4956) | 195.1 (4956) | 195.1 (4956) |

| Width – in (mm) | 87 (2210) | 87 (2210) | 87 (2210) | 87 (2210) |

| Height – in (mm) | 85.4 (2169) | eighty five.4 (2169) | eighty five.4 (2169) | 85.4 (2169) |

| Transport Weight _ No Fuel – lb (kg) | 7,650 (3450) | 7,650 (3450) | 7,650 (3450) | 7,650 (3450) |

The use of first gear manufacturer’s (OEM) portion quantities or logos , e.g. CASE® and John Deere® are for reference functions only and for indicating merchandise use and compatibility. Our organization and the listed substitution components contained herein are not sponsored, authorized, or manufactured by the OEM.

Double shop made in China – replacement parts – in Natal Brazil Screw Extruder for Powder Coating with top quality

We – EPG Team the most significant gearbox & motors , torque limiter couplings and gears manufacturing unit in China with 5 different branches. For much more particulars: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778083988828

one. Mixers:

one.1 Automatic Container Mixer

Automated container mixer is wor ept with coThe quantity of torque transmitted is set by the pressure used by the DISC SPRING which is modified by loosening or tightening the ADJUSTMENT NUT. When sought after torque environment is achieved, a Established SCREW locks the ADJUSTMENT NUT in place.ntinuous materials trolleys, the container fills the materials and lifted up and connnected tightly with mixing head immediately. The mixing head tilts jointly with the containers, and then get the homogeneous mixing outcome, soon after finishing mixing as for each location time, and return to authentic place, the complete procedure will be managed by PLC

Major Attributes:

Many detachable containers for round operation

High efficiency

Adopting PLC to realize automation

Homogenized combination

No curing granule

Practical for cleansing and maintenance

Risk-free and relaiable procedure

Specialized Knowledge:

| Design | Quantity (L) | Output (kg/tank) | Mixing Motor (kw) | Tilting Motor (kw) | Crushing Motor (kw) | Mixing Time (min) | Management Mode | All round Proportions (MM) |

| FHJ-15 | 15 | eight | 1.five | five-ten | PLC | 750*480*950 | ||

| FHJ-one hundred twenty | 120 | 60 | 5.5 | .two | 5-ten | PLC | 1800*1800*1950 | |

| FHJ-150 | 150 | 70 | five.5 | .37 | two.2 | five-10 | PLC | 2150*1100*2300 |

| FHJ-three hundred | 300 | a hundred and fifty | fifteen | 3 | 2.2 | 5-ten | PLC | 2150*1100*2300 |

| FHJ-600 | 600 | three hundred | 22 | 4 | four | 5-10 | PLC | 2650*1250*2700 |

| FHJ-one thousand | 1000 | five hundred | 30 | 4 | 4 | 5-10 | PLC | 2900*1550*3100 |

| FHJ-2000 | 2000 | one thousand | forty five | five.five | 5.5 | five-ten | PLC | 3500*2350*3650 |

one.2 High Speed Pre-Mixer:

Attributes:

Large effectiveness & effortless operation

Simple coloration altering, secure cleansing

Merged mixing & crushing as one

Mixing time preseting, brief & homogeneous

Exceptional sealing, powder lea ept free of charge

Vertical or horizontal sort as optional

Technological Data:

| Design | Quantity (L) | Mixing Motor (kw) | Crushing Motor (kw) | Mixing Time (min) | Overall Dimensions (mm) |

| GHJ-twenty | 20 | .fifty five | .37 | three-5 | seven hundred*500*800 |

| GHJ-a hundred | 100 | three | 1.5 | 3-5 | one thousand*600*900 |

| GHJ-two hundred | 200 | five.5 | 3 | 3-five | 1500*900*1400 |

| GHJ-three hundred | three hundred | 7.five | four | 3-six | 1800*900*1400 |

| GHJ-500 | five hundred | 15 | 5.5 | four-six | 1800*1300*1800 |

| GHJ-800 | 800 | eighteen.five | seven.five | four-six | 1900*1300*2000 |

| GHJ-1000 | a thousand | 22 | seven.5 | 4-six | 2300*1400*2000 |

one.3 Double Cone Mixer:

This twin-cone mixer is composed of a rotating container with two cones and two stirrers. This equipment is relevant for powder coating, pharmaceutical, chemical, foodstuff, dyestuff, and other multi-compound resources. It has remarkable influence in mixing powders and particles with fairly good fluidity. Its barrel is created of stainless metal, which is polished the two within and outside the house, showcasing lovely physical appearance and easy operation.

Technical Knowledge:

| Product | Quantity (L) | Output (kg/tank) | Rotating Motor (kw) | Mixing Motor (kw) | Mixing Time (min) | Total Dimensions (mm) |

| SXH-one hundred | three hundred | a hundred and fifty | 1.5 | 1.5 | -thirty | 1760*830*2030 |

| SXH-two hundred | 400 | 200 | one.5 | 1.5 | -thirty | 1830*830*2150 |

| SXH-300 | 600 | three hundred | 2.2 | 1.5 | -thirty | 1980*1000*2275 |

| SXH-500 | one thousand | five hundred | four | four | 1-thirty | 2630*1140*2620 |

| SXH-1000 | 2000 | one thousand | 5.5 | five.five | -30 | 3060*1440*2860 |

| SXH-1500 | 3000 | 1500 | 7.5 | seven.five | -thirty | 3700*2000*2970 |

| SXH-2000 | 4000 | 2000 | eight.five | 8.5 | -thirty | 3800*2500*3500 |

two. Twin-Screw Extruder

2.1 Higher torque & Substantial Speed Rotation Twin-Screw Extruder:

Main Characteristics:

*Full Gearbox from specialist EPT maker, minimal sounds, sturdy longevity

*Large screw velocity, high shearing, quick discharge

*Impartial lube oil cooling method design and style

*Torque limiter to defend the generate prepare

*Suitable for reclaim powder, specific powder manufacturing

*Break up design of barrel and liner inserts for straightforward cleansing and maintainence

*Top & Side feeding options

*Other attributes exact same as traditional kind extruder

Specialized Parameters:

| Design | Capability (kg/h) | Screw Diameter (mm) | Screw Size (mm) | Screw Pace (r/min) | Major Motor (kw) | Feeder Motor (kw) | Heating Electrical power (kw) | Total Proportions (mm) |

| TSX-forty | 80-260 | 40 | 16D | -800 | 11/fifteen/18.5 | .fifty five | 8 | 1850*seven hundred*1750 |

| TSX-52 | one hundred fifty-450 | 52 | 16D | -800 | 22/thirty/37 | .seventy five | ten | 2700*900*2200 |

| TSX-sixty five | four hundred-a thousand | 65 | 16D | -800 | forty five/55/75 | one.one | 12 | 2900*a thousand*2400 |

| TSX-seventy five | 800-1200 | seventy five | 16D | -800 | 75/90 | 1.five | sixteen | 3100*1200*2500 |

| TSX-eighty five | 1200-1800 | eighty five | 16D | -800 | 90/a hundred and ten | 2.two | twenty | 3700*1500*2900 |

two.2 Typical Variety Co-Rotation Parallel Twin Screw Extruder

Functions:

*Robust shearing, effortless cleansing

*Accurate automobile temperature control, substantial cooling & heating exchagne

*Hinged clamshell type barrel opening, segmented liners for straightforward replacing and cost conserving

*Feeder straightforward assembly & disassembly, interior structure to keep away from agglomeration

*Configurable screw used for defferent powder formulation

*Screw and barrel adopt particular components like Cr12MoV, CPM, and so on., large wearing resisting

*Really gearbox with low sounds dB stage

*Torque limiter to protect the travel prepare

*Minimal vitality consumption

Technical Parameters:

| Design | Ability (kg/h) | Screw Diameter (mm) | Screw Size | Screw Pace (r/min) | Major Motor (kw) | Feeder Motor (kw) | Heating Electrical power (kw) | General Proportions (mm) |

| SLJ-forty | 80-220 | forty | 16D | -five hundred | 11/fifteen/18.5 | .55 | 4 | 1800*600*1700 |

| SLJ-50 | a hundred and fifty-300 | 50 | 16D | -500 | 22/thirty | .seventy five | 8 | 2600*seven hundred*2000 |

| SLJ-fifty five | three hundred-400 | 55 | 16D | -500 | 30/37 | .75 | eight | 2700*900*2300 |

| SLJ-sixty | 400-600 | 60 | 16D | -500 | forty five | one.1 | twelve | 2750*one thousand*2350 |

| SLJ-75 | 600-800 | seventy five | 16D | -500 | fifty five | one.5 | twelve | 2900*1100*2400 |

| SLJ-eighty | 800-1200 | 80 | 16D | -500 | 75/90 | two.two | twenty | 3700*800*2800 |

two.3 Lab Kind Extruder

Specialized Parameters:

| Product | Capability (kg/h) | Screw Diameter (mm) | Screw Size | Screw Pace (r/min) | Principal Motor (kw) | Feeder Motor (kw) | Heating Energy (kw) | General Dimensions (mm) |

| TSX-twenty | .2-ten | 22 | 16D | -600 | 2.2-4 | .one | 2 | 1600*three hundred*850 |

| SLJ-30 | one-thirty | thirty | 16D | -five hundred | 3-5.five | .eighteen | three.2 | 1430*550*1300 |

| SLJ-32 | forty-80 | 32 | 16D | -five hundred | 7.5/11 | .twenty five | 3.two | 1600*500*1500 |

three Cooling Belt

3.1 H2o Cooled Cooling Belt with Flaker:

Characteristics:

Constant good quality imported metal belt

Bottom cooling drinking water spraying program, set up heating and cooling gadget

Outfitted with information device to stay away from deforming

Better cooling end result, higher efficient productivity

Couple of upkeep and easy cleansing

Chips thickness and roller speed adjustable

Crusher with finger pin and enamel variety

Minimized cross contamination, simple operation

Complex Parameters:

| Model | Roller Dia. (mm) | Belt Width (mm) | Belt Size (mm) | Travel Motor (kw) | Ability (kg/h) | Cooling Mode | All round Dimensions (mm) |

| GDY-406 | 220 | 600 | 4000 | 1.5 | two hundred-four hundred | Cooled H2o | 4000*750*1600 |

| GDY-508 | 325 | 800 | 5000 | 3 | four hundred-five hundred | Cooled Drinking water | 5000*900*1800 |

| GDY-510 | 325 | a thousand | 5000 | 3 | five hundred-seven hundred | Cooled Water | 5000*1100*1900 |

| GDY-610 | 440 | 1000 | 6000 | 4 | 600-800 | Cooled H2o | 6000*1100*1900 |

| GDY-612 | 440 | 1200 | 6000 | 4 | seven hundred-900 | Cooled H2o | 6000*1400*1900 |

| GDY-712 | 600 | one thousand | 7000 | 5.five | 900-1200 | Cooled Drinking water | 7000*1400*2000 |

3.2 Air Cooled Sort Caterpillar Cooling Belt with Flaker:

Features:

Stainless steel made caterpillar, air cooling

Flake chips thichness and conveying velocity adjustable

Reasonable design for cooling rollers inside of, skilled area treatment method to steer clear of h2o lea ept and rust

Put in with simplified air conditioning device

Safe procedure, like unexpected emergency button, clockwise and counter-clockwise rotation.

Technological Parameters:

| Model | Roller Dia. (mm) | Belt Width (mm) | Belt Size (mm) | Push Motor (kw) | Blower Motor (kw) | Capacity (kg/h) | Cooling Method | Overall Dimensions (mm) |

| JFY-204 | one hundred sixty/160 | 400 | 2000 | .55 | two hundred-400 | thirty-100 | Chilled Water&Air | 2000*450*900 |

| JFY-406 | one hundred sixty/220 | 600 | 4000 | .75 | four hundred-500 | one hundred-220 | Chilled Drinking water&Air | 4000*850*950 |

| JFY-508 | a hundred and eighty/325 | seven-hundred | 5000 | .seventy five | 500-700 | 220-four hundred | Chilled H2o&Air | 5000*1050*1200 |

| JFY-510 | a hundred and eighty/325 | 800 | 5000 | 1.one | 600-800 | four hundred-five hundred | Chilled Drinking water&Air | 5000*1150*1200 |

| JFY-610 | a hundred and eighty/325 | 800 | 6000 | 1.one | seven hundred-900 | 500-seven hundred | Chilled H2o&Air | 6000*1150*1200 |

| JFY-710 | 180/325 | a thousand | 6000 | 1.five | 900-1200 | 600-900 | Chilled Drinking water&Air | 7000*1250*1450 |

| JFY-812 | 180/325 | one thousand | 7000 | two.two | 900-1200 | 900-1200 | Chilled H2o&Air | 8000*1650*1600 |

three.3 PU Type Air Cooled Cooling Belt

Functions:

Adjustable thichness and roller speed

Air cooled to steer clear of cross contamination

Roller and crusher outfitted with overload safety

Substantial efficiencies

One particular piece PU belt to faciliate simple cleansing and routine maintenance

Compact style for minimal area

Technological Parameters:

| Design | Roll Dia. (mm) | Band Width (mm) | Band Duration (mm) | Motor Power (kw) | Throughput (kg/h) | Proportions (mm) |

| PFY-104 | 156 | 400 | one thousand | one.1 | 50 | 1000*870*1050 |

| PFY-206 | 220 | 600 | 2000 | one.one | 150 | 2000*1150*1100 |

| PFY-208 | 445 | 800 | 2000 | two.two | three hundred | 2000*1100*1100 |

| PFY-210 | 445 | one thousand | 2000 | 2.two | 500 | 2000*1300*1100 |

| PFY-310 | 622 | 1000 | 3000 | two.2 | 800 | 2000*1300*1200 |

4 ACM (Air Classifier Mill) Grinding Method

Features:

Security in accordance with EU explosion resistant standard ATEX/PSR11

Lower sound style (from mill to admirer program)

Particle size distribution adjustable on request

Mill body temperature and air ingestion volume monitoring

Rotary sieve with exclusive design and durable for mesh wear issue

Entire grinding method made for powder dust free of charge

Completed powder items with much more than 98 %

High output, easy operation cleaning and upkeep

Specialized Parameters:

| Product | Mill Motor kw | Rotor rpm | Classifier Motor | Classifier rpm | Supporter kw | Air cbm/h | Potential kg/h | General dimensions mm |

| ACM-02 | 2.two | 12000 | .37 | -3000 | three | 350 | two-thirty | 1430*550*1300 |

| ACM-05 | four | 11000 | .seventy five | -3000 | four | 800 | 30-eighty | 2100*1000*2150 |

| ACM-ten | 7.5 | 7000 | one.5 | -3000 | 11 | 2500 | 100-260 | 6200*1250*3200 |

| ACM-15 | eleven | 7000 | one.five | -3000 | 15 | 3000 | 200-350 | 6500*1300*3300 |

| ACM-20 | fifteen | 6600 | two.two | -3000 | 22 | 3500 | three hundred-400 | 7500*1300*3600 |

| ACM-30 | 22 | 5500 | three | -3000 | 30 | 4500 | four hundred-550 | 7900*1500*3600 |

| ACM-40 | 30 | 4600 | five.5 | -3000 | 37 | 5500 | 600-800 | 8000*1700*3600 |

| ACM-fifty | 37 | 4000 | 7.5 | -3000 | 45 | 6500 | one thousand-1200 | 9000*1900*3900 |

| ACM-60 | forty five | 3500 | 7.five | -3000 | fifty five | 8000 | 1200-1600 | 9000*2000*4000 |

Company:

Xihu (West Lake) Dis.sun is a foremost maker in China of Powder Coating Manufacturing Equipments, i.e. Mixers, Extruders, Cooling Belt and Air Classifier Mill. We inherit thirty many years of activities in this ept and have exported to practically thirty nations and regions in the past 10 a long time, and win commonly good reputations.

We handed CE certification acceptance and ATEX explosion resistant test, and many others. worldwide expectations, we do know how to meet up with the diversified and tailored made requests of our customers.

Our eternal company philosophy: consistant quality, effective communication, dependable support.

The use of authentic gear manufacturer’s (OEM) component figures or logos , e.g. CASE® and John Deere® are for reference purposes only and for indicating solution use and compatibility. Our company and the outlined alternative components contained herein are not sponsored, authorized, or created by the OEM.

High manufacturer made in China – replacement parts – in Grande Vitoria Brazil Torque & High Speed Rotation Twin Screw Extruder for Powder Coating Paint Extrusion with top quality

We – EPG Group the largest gearbox & motors , torque limiter couplings and gears manufacturing unit in China with 5 various branches. For much more specifics: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778083988828

High torque & High Speed Rotation Twin-Screw Extruder:

Web site: , cn

Primary Attributes:

*Straightforward to use and easy to clear

*Sophisticated heating and through-shaft cooling

*particular energy and torque maximise output with out wasting power

*Torque limiter to protect the travel practice

*Precise and responsive temperature control over barrel

*Split style of barrel and liner inserts for effortless cleansing and maintainence

*Leading & Side feeding possibilities

*Stainless go over for protection and physical appearance

Specialized Parameters:

| Design | Capacity (kg/h) | Diameter (mm) | Screw Size (mm) | Screw Speed (r/min) | Primary Motor (kw) | Feeder Motor (kw) | Heating Electrical power (kw) | Total Proportions (mm) |

| TSX-forty | eighty-260 | forty | 16D | -800 | 11/fifteen/eighteen.5 | .55 | 8 | 1850*700*1750 |

| TSX-fifty two | 150-450 | fifty two | 16D | -800 | 22/30/37 | .seventy five | ten | 2700*900*2200 |

| TSX-sixty five | four hundred-1000 | 65 | 16D | -800 | 45/fifty five/75 | 1.1 | 12 | 2900*a thousand*2400 |

| TSX-seventy five | 800-1200 | seventy five | 16D | -800 | 75/ninety | 1.5 | sixteen | 3100*1200*2500 |

| TSX-85 | 1200-1800 | 85 | 16D | -800 | ninety/a hundred and ten | 2.2 | twenty | 3700*1500*2900 |

Firm:

Xihu (West Lake) Dis.sun is a leading producer in China of Powder Coating Manufacturing Equipments, i.e. Mixers, Extruders, Cooling Belt and Air Classifier Mill. We inherit thirty years of encounters of this ept and have exported to virtually 30 nations and locations in the previous 10 several years, and win widely good reputations.

We handed CE certification approval and ATEX explosion resistant examination, and many others. intercontinental expectations, we do know how to meet up with the diversified and custom-made produced requests of our customers.

Our everlasting enterprise philosophy: consistant good quality, effective communication, responsible support.

Substantial torque & High Velocity Rotation Twin-Screw Extruder:

1. Primary Features:

*Complete Gearbox from specialist EPT maker, minimal sounds, tough longevity

*Large screw velocity, large shearing, quick discharge

*Impartial lube oil cooling technique design

*Torque limiter to defend the push train

*Suited for reclaim powder, unique powder production

*Split layout of barrel and liner inserts for straightforward cleaning and servicing

*Best & Side feeding options

*Other attributes identical as traditional type extruder

two. Specialized Parameters:

| Design | Potential (kg/h) | Screw Diameter (mm) | Screw Size (mm) | Screw Velocity (r/min) | Major Motor (kw) | Feeder Motor (kw) | Heating Electrical power (kw) | Total Dimensions (mm) |

| TSX-40 | 80-260 | forty | 16D | -800 | eleven/15/18.5 | .fifty five | 8 | 1850*seven hundred*1750 |

| TSX-fifty two | one hundred fifty-450 | 52 | 16D | -800 | 22/30/37 | .seventy five | ten | 2700*900*2200 |

| TSX-65 | four hundred-1000 | sixty five | 16D | -800 | 45/fifty five/75 | one.1 | 12 | 2900*1000*2400 |

| TSX-seventy five | 800-1200 | seventy five | 16D | -800 | 75/ninety | 1.five | 16 | 3100*1200*2500 |

| TSX-eighty five | 1200-1800 | 85 | 16D | -800 | ninety/110 | 2.2 | 20 | 3700*1500*2900 |

3. Typical Variety Co-Rotation Parallel Twin Screw Extruder

four. Features:

*Strong shearing, effortless cleaning

*Accurate automobile temperature manage, higher cooling & heating exchagne

*Hinged clamshell variety barrel opening, segmented liners for easy changing and value preserving

*Feeder simple assembly & disassembly, inner framework to keep away from agglomeration

*Configurable screw utilized for various powder formulation

*Screw and barrel adopt special materials like Cr12MoV, CPM, and many others., higher wearing resisting

*Really gearbox with low noise dB level

*Torque limiter to defend the travel train

*Low energy intake

five. Technical Parameters:

| Design | Potential (kg/h) | Screw Diameter (mm) | Screw Size | Screw Speed (r/min) | Major Motor (kw) | Feeder Motor (kw) | Heating Electrical power (kw) | General Proportions (mm) |

| SLJ-forty | eighty-220 | 40 | 16D | -five hundred | eleven/15/eighteen.five | .fifty five | four | 1800*600*1700 |

| SLJ-50 | a hundred and fifty-three hundred | 50 | 16D | -five hundred | 22/thirty | .seventy five | eight | 2600*seven-hundred*2000 |

| SLJ-fifty five | 300-four hundred | 55 | 16D | -500 | 30/37 | .75 | eight | 2700*900*2300 |

| SLJ-sixty | four hundred-600 | 60 | 16D | -five hundred | forty five | 1.one | 12 | 2750*a thousand*2350 |

| SLJ-75 | 600-800 | 75 | 16D | -500 | fifty five | one.five | 12 | 2900*1100*2400 |

| SLJ-eighty | 800-1200 | eighty | 16D | -500 | seventy five/ninety | 2.two | 20 | 3700*800*2800 |

six. Technical Parameters (Lab Sort):

| Model | Ability (kg/h) | Screw Diameter (mm) | Screw Size | Screw Pace (r/min) | Major Motor (kw) | Feeder Motor (kw) | Heating Electricity (kw) | Total Dimensions (mm) |

| TSX-20 | .2-ten | 22 | 16D | -600 | 2.2-four | .1 | 2 | 1600*three hundred*850 |

| SLJ-thirty | 1-thirty | thirty | 16D | -500 | 3-5.five | .18 | 3.two | 1430*550*1300 |

| SLJ-32 | forty-eighty | 32 | 16D | -five hundred | seven.5/eleven | .25 | three.two | 1600*500*1500 |

7. Firm:

Xihu (West Lake) Dis.sunshine is a leading manufacturer in China of Powder Coating Generation Equipments, i.e. Mixers, Extruders, Cooling Belt and Air Classifier Mill. We inherit thirty many years of ordeals in this ept and have exported to virtually thirty international locations and locations in the previous 10 a long time, and win commonly very good reputations.

We handed CE certification acceptance and ATEX explosion resistant check, and so forth. intercontinental specifications we do know how to meet the diversified and tailored made requests of our clients.

Our eternal business philosophy: consistant high quality, powerful communicatimechanical torque-restricting gadgets count on springs (with specific damaging rate qualities) that work in unison with a torque transmission program of balls interfacing two indents. In this set up, preset torque is retained inside an acceptable placing tolerance and makes certain that even beneath very dynamic drive conditions, the clutch disengages in the course of overload.on, dependable support.

eight. Why choosing us?

Our boss has worked in this ept for much more than thirteen many years.

Our vice GM has worked in this ept for more than twenty a long time.

Our technical supervisor has worked in this ept for more than 7 years.

Our production supervisor has worked in this ept for more than 8 years.

We have an superb staff. We are experienced, excellent, friendly and accountable, with a view to extended term cooperation.

The use of unique products manufacturer’s (OEM) component figures or emblems , e.g. CASE® and John Deere® are for reference needs only and for indicating solution use and compatibility. Our company and the detailed substitution parts contained herein are not sponsored, approved, or manufactured by the OEM.

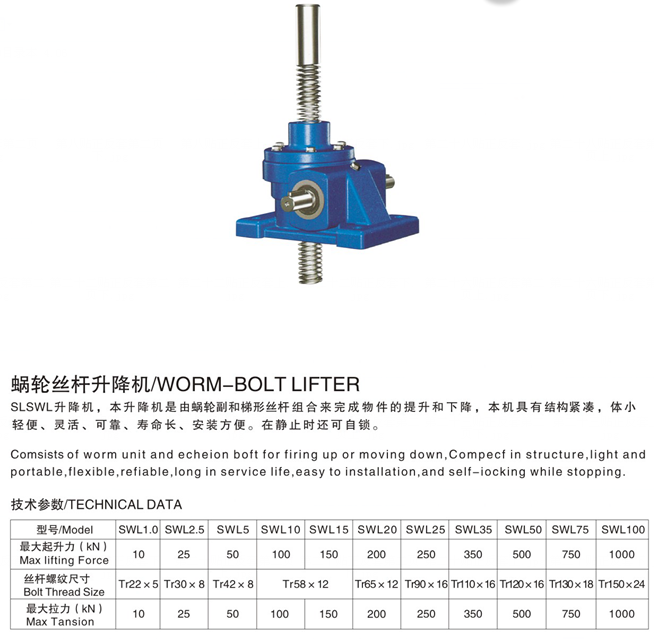

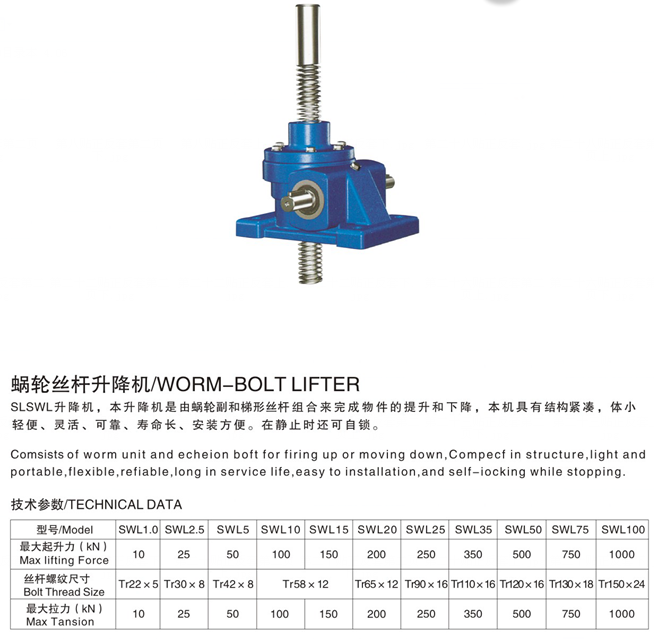

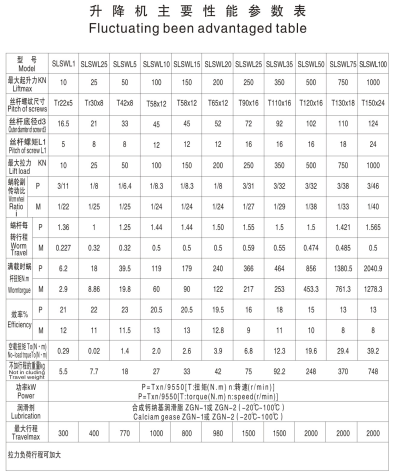

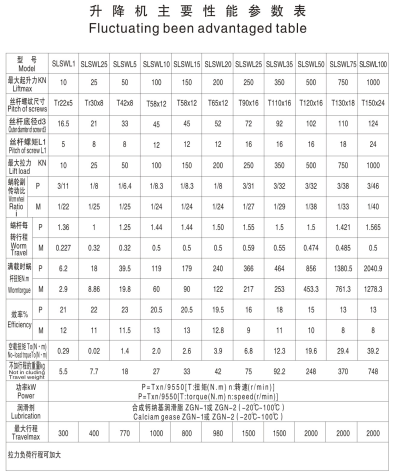

Best China manufacturer & factory SWL series worm mechanical types of screw jack lifter screw jack speed reducer power transmission With high quality best price

We are aiming to meet the demands of the clients around the world.. a specialized supplier of a full range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes…Under the guidance of managerial sense of “Serving agriculture, scoring a success through quality of products and honesty in business”, our products have been trusted by clients and have gained a larger share of market..

Maintenance Maintenance on these units is straight forward and like all moving parts these need their fair share of grease and should be greased regularly as these components work very hard and are subject to all that nature can provide for wear and tear. Good grease is essential here; put grease in until you see the old grease oozing out. Go easy on the “U” joints so you don’t blow the seals. Short bursts of a low pressured air grease gun or even better a hand pump gun will do the job and should be done based on hourly use. At least once a season the primary and secondary shafts should be separated. All debris and any rust should be cleaned off. Examine thoroughly for any signs of stress and apply a liberal amount of grease. In addition to this, both the PTO yoke holes need grease inside of them at least once a year along with the yoke lock pin.

Overview

Quick Details

- Applicable Industries:

-

Building Material Shops

- Gearing Arrangement:

-

worm

- Output Torque:

-

–

- Input Speed:

-

–

- Output Speed:

-

–

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Certification:

-

ISO9001-2008

- Lifting Capacity:

-

As request

- Lifting Height(mm):

-

As request

- Gear material:

-

Low carbon high alloy steel

- Heat treatment:

-

Carburising, quenching, gear grinding

- Diameter & Length of Screw:

-

Designed as request

- Bearing:

-

U&C

Supply Ability

- Supply Ability:

- 500 Unit/Units per Month

Packaging & Delivery

- Packaging Details

- Standard exporting package

- Port

- Ningbo Port, Shanghai Port

Online Customization

SWL series worm mechanical types of screw jack lifter screw jack speed reducer power transmission

Product Description

SWL worm mechanical types of screw jack lifter has the features of compacted structure, light and portable, flexible, reliable, long service life, easy to installation, and self-locking while stop.

| Certification | ISO9001-2008 |

| Lifting Capacity | As request |

| Lifting Height(mm) | As request |

| Overall Width(mm) | As request |

| Gear material | Low carbon high alloy steel |

| Heat treatment | Carburising, quenching, gear grinding |

| Diameter & Length of Screw | Designed as request |

| Bearing | C&U |

| gear precision grade | din 4 |

Company Information

Certifications

Our Services

Packaging & Shipping

RV025~RV150 Solid Shaft Input RV025~RV150 Features: 1. Quality aluminum alloy gear box, light weight and not rust 2. 2 optional worm wheel materials: Tin (Stannum) bronze or aluminum bronze alloy 3. Standard parts and very flexible for shaft configurations and motor flange interface 4. Several optional mounting options 5. Low noise, High efficiency in heat dissipation

Related Products

FAQ

: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

Contact us

Best China manufacturer & factory SLP series planetary speed reducer gearbox transmission mechanical speed variator jack screw actuator With high quality best price

Our technicians and engineers have 23 years of Experience in the Bearing Industry.

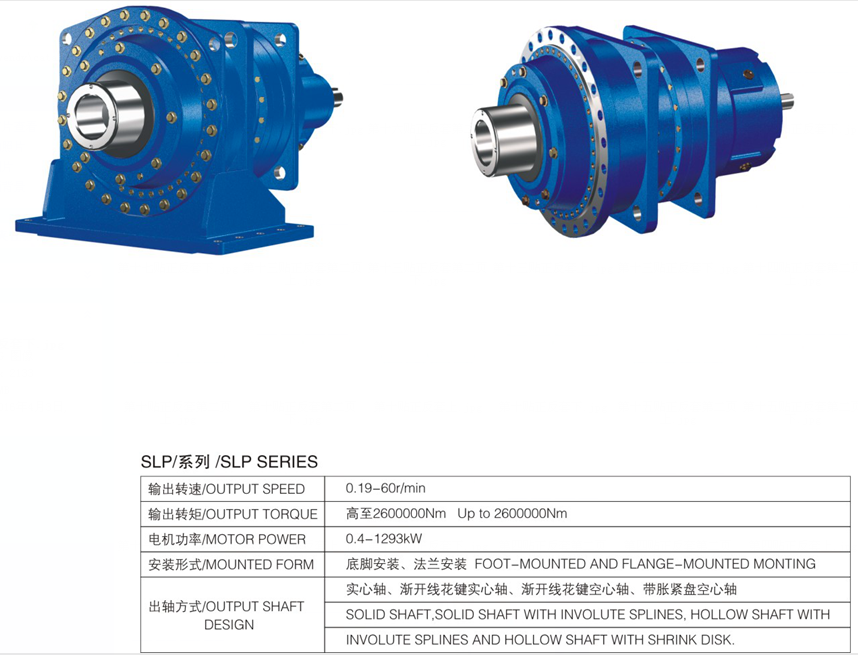

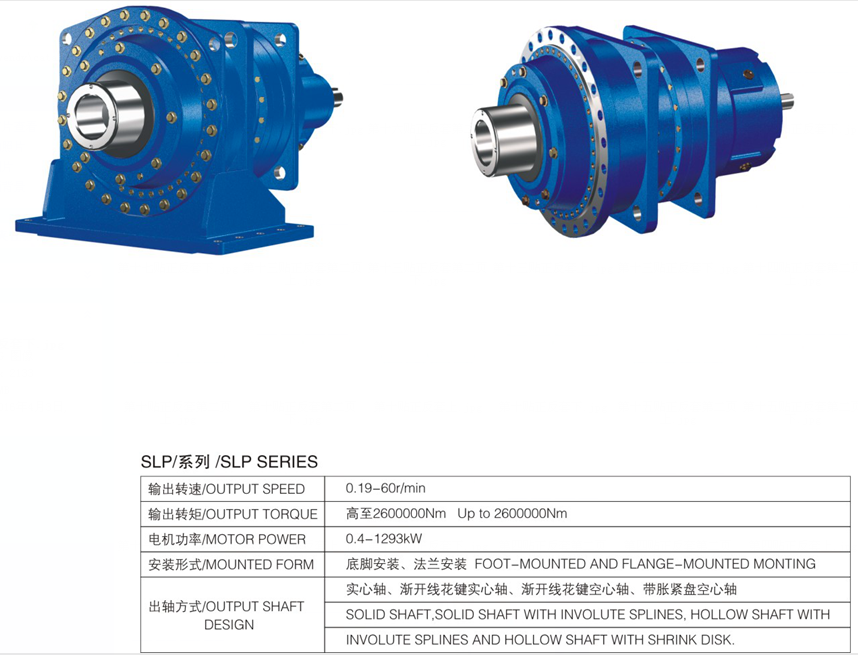

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, farms

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Gearing Arrangement:

-

Planetary

- Output Torque:

-

Up to 260000Nm

- Input Speed:

-

750-1500rpm

- Output Speed:

-

0.19-60rpm

- Certification:

-

ISO9001-2008

- Mount Position:

-

Foot Mounted

- Bearing:

-

C & U

- gear precision grade:

-

din 4

Supply Ability

-

Aside from gear ratio, the most important factor that determines efficiency is the contact pattern between worm and mating gears. Manufacturing the reducer housing, and worm and gear subassemblies creates a stack up of tolerances, so the position of the gear-toAT series with tri-lobe tube (triangular) The triangular tube shape is the most used, from lightweight to fairly heavy applications. In the case of applications with high sliding, the R version with Rilsan coating is also available. AL series with two-lobe tubes (lemon).oth centerline cannot be accurately predicted. Therefore, assemblers must manually measure and adjust the contact pattern by varying the position of shims behind the front and rear bearings on the output gear shaft. This is timeconsuming and costly, so most manufacturers use statistical analysis to predict shim quantity and location. This provides a reasonably centered contact pattern most of the time.

- Supply Ability:

- 500 Unit/Units per Month

Packaging & Delivery

- Packaging Details

- Standard wooden case

- Port

- Ningbo Port, Shanghai Port

Online Customization

Product Description

SLP series planetary speed reducer gearbox transmission mechanical speed variator jack screw actuator

Advantage:

SLP series planetary speed reducer has the features of light weight, small volume, high transmission ratio, high efficiency, smooth rotation, low noise and good applicability.

1) Output speed:0.19~60r/min

2) Outpu EPG is specialized in design, manufacturer and sales of agricultural machinery and farm implements, which has an independent import and export rights. t torque: up to 260,000N.m

3) Motor power: 0.4~1293kW

4) Mounted form: foot-mounted ,flange-mounted

Main application:

Mixers / Agitator,Roller presses,Conveyor drives,Shredders ,Filtration technology,Water treatment,Reactors,Travel drives,Feeder,Mill

Certifications

Trade Shows

Packaging & Shipping

Packing Details : Standard carton/Pallet/Standard wooden case

Delivery Details : 15-30 working days upon payment

Company Information

other series product

| Precision Planetary gearbox | Robot RV gearbox speed reducer |

| Custom made Non-standard Gearbox | UDL Series Variator |

| PYZ Series Helical Tooth Shaft Mounted Reducer | 8000 Series Cycloidal Reducer |

| SLT Series Spiral Bevel Gearbox | SLSWL Series Worm Screw Jack |

| SLP Series Planetary Reducer | SLH/SLB Series High Power Reducer |

| NMRV Series Worm Reducer | BKM Series Helical-hypoid Reducer |

| SLRC Series Helical Reducer | SLSMR Series Shaft Mounted Reducer |

| SLXG Series Shaft Mounted Reducer | X/B Series Cycloidal Reducer |

| SLR/SLF/SLK/SLS Series Helical Reducer |

Related Products

Contact

Gearbox China series 5 pto shaft in Mandalay Myanmar with Double Output Shaft Gearbox for Pto Speed Increase Industrial Gearbox Types Type Transmissions Screw Jacks with ce certificate top quality low price

We – EPG Team the biggest agricultural gearbox and pto factory in China with five different branches. For more specifics: Cellular/whatsapp/telegram/Kakao us at: 0086-13083988828

cheap pto shafts Under pto shaft friction clutch the 1967 mustang driveshaft direction tractor pto shaft mend of shaft tractor managerial pto shaft image feeling 2007 lincoln mkz travel shaft of 491003e951 “Serving e39 m5 driveshaft agriculture, tractor pto shaft with clutch scoring a good results by means of quality of items and honesty in organization”, our goods have been trustworthy by customers and have received a greater share of marketplace. Adhering to “Survival by High quality, Advancement by Engineering & Credit”, The business will constantly boost merchandise efficiency to fulfill the growing buyer needs in the demanding type of perform.

Lower value NMRV sequence worm gear utilised maritime gearbox for sale,cheap worm equipment box prices for textile equipment

Solution Description

NMRV Employed Maritime Gearbox

one. Mad of substantial-good quality aluminum alloy,mild weight and non-rusting

2. Massive output torque

three. Easy in managing and lower in sounds,can work extended time in dreadful problems.

4. Higher in radiating performance.

5. Very good-searching in visual appeal,resilient in service life and modest in volume.

6. Ideal for omnibearing installation.

| Design No.: | NMRV571, NMRV030, NMRV040, NMRV050, NMRV063, NMRV075, NMRV090, NMRV110, NMRV130, NMRV150 |

| Ratio: | five,7.5,ten,15,20,25,30,forty,50,60,eighty,100 |

| Color: | Blue(Ral5571)/Silver Gray (RAL9006) Or On Buyer Request |

| Content: | Housing: Measurement 25-one hundred ten Is Aluminum Alloy, Dimension one hundred ten-a hundred and fifty Is Cast-Iron |

| Worm Wheel: ZCuSn10Pb1 | |

| Worm:20Cr | |

| Pinion:Tin Bronze | |

| Output Shaft: Steel-forty five# | |

| Usages: | Industrial Equipment: Foodstuff Things, Ceramics, Chemical, Packing, Dyeing,Wooden operating, Glass. |

| IEC Flange: | IEC StHangZhourd Flange Or On Consumer Ask for |

Company Information

Top quality handle

Packing

Packing Details: StHangZhourd carton/Pallet/StHangZhourd wooden situation

Supply Detai EPT : fifteen-30 working times on payment

Our Certifications

Associated Solution

Precision Planetary gearbox

| Precision Planetary gearbox | Robotic RV gearbox velocity reducer |