Product Description

SC Transmission FCL Flexible Shaft Couplings for Reducer and Motor

Product Description

FCL Coupling/Shaft Coupling /Pin & Bush Coupling /FCL Flexible Coupling/NBK FCL Coupling is widely used for its compacts designing, easy installation, convenient maintenance, small and light weight.

As long as the relative displacement between shafts is kept within the specified tolerance, couplings will operate the best function and have a longer working life.

Thus it is greatly demanded in medium and minor power transmission systems driven by motors, such as speed reducers, hoists, compressors, conveyors, spinning and weaving machines and ball mills.

Product Parameters

| SIZE | D | D1 | d1 | L | C | n-M | kg | |||

| r/min | ||||||||||

| N.m | ||||||||||

| FCL90 | 4 | 4000 | 90 | 35.5 | 11 | 28 | 3 | 4-M8 | 1.7 | |

| FCL100 | 10 | 4000 | 100 | 40 | 11 | 35.5 | 3 | 4-M10 | 2.3 | |

| FCL112 | 16 | 4000 | 112 | 45 | 13 | 40 | 3 | 4-M10 | 2.8 | |

| FCL125 | 25 | 4000 | 125 | 65 | 50 | 13 | 45 | 3 | 4-M12 | 4 |

| FCL140 | 50 | 4000 | 140 | 71 | 63 | 13 | 50 | 3 | 6-M12 | 5.4 |

| FCL160 | 110 | 4000 | 160 | 80 | 15 | 56 | 3 | 8-M12 | 8 | |

| FCL180 | 157 | 3500 | 180 | 90 | 15 | 63 | 3 | 8-M12 | 10.5 | |

| FCL200 | 245 | 3200 | 200 | 100 | 21 | 71 | 4 | 8-M20 | 16.2 | |

| FCL224 | 392 | 2850 | 224 | 112 | 21 | 80 | 4 | 8-M20 | 21.3 | |

| FCL250 | 618 | 2550 | 250 | 125 | 25 | 90 | 4 | 8-M24 | 31.6 | |

| FCL280 | 980 | 2300 | 280 | 140 | 34 | 100 | 4 | 8-M24 | 44 | |

| FCL315 | 1568 | 2050 | 315 | 160 | 41 | 112 | 4 | 10-M24 | 57.7 | |

| FCL355 | 2450 | 1800 | 355 | 180 | 60 | 125 | 5 | 8-M30 | 89.5 | |

| FCL400 | 3920 | 1600 | 400 | 200 | 60 | 125 | 5 | 10-M30 | 113 | |

| FCL450 | 6174 | 1400 | 450 | 224 | 65 | 140 | 5 | 12-M30 | 145 | |

| FCL560 | 9800 | 1150 | 560 | 250 | 85 | 160 | 5 | 14-M30 | 229 | |

| FCL630 | 15680 | 1000 | 630 | 280 | 95 | 180 | 5 | 18-M30 | 296 | |

Company Profile

FAQ

Shipping

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What are the temperature and environmental limitations of flexible couplings?

Flexible couplings are designed to operate within certain temperature and environmental limitations to ensure optimal performance and longevity. The specific limitations may vary depending on the type and material of the coupling. Here are the general considerations:

- Temperature Range: The temperature range in which a flexible coupling can operate is crucial. High temperatures can affect the material properties, leading to reduced flexibility and potential failure. Low temperatures can cause the material to become brittle and lose its ability to accommodate misalignment. It’s essential to choose a coupling suitable for the intended temperature range of the application.

- Corrosive Environments: In environments with corrosive substances, such as acids, chemicals, or saltwater, it is essential to select a flexible coupling made of materials that are resistant to corrosion. Stainless steel and certain polymers are commonly used in such environments to prevent degradation and maintain the coupling’s integrity.

- Hygienic Environments: For applications in food processing, pharmaceuticals, or cleanrooms, hygienic design is critical. Flexible couplings used in these environments should be easy to clean, made of materials that are non-toxic and resistant to contamination, and free from crevices or pockets where debris can accumulate.

- Explosive or Hazardous Atmospheres: In environments where explosive or hazardous gases, vapors, or dust are present, flexible couplings with anti-static properties or explosion-proof certifications may be necessary to prevent the risk of ignition and ensure safety.

- Outdoor Applications: For outdoor installations, flexible couplings should be able to withstand exposure to weather conditions, UV radiation, and temperature fluctuations. Couplings with weather-resistant properties are suitable for such applications.

- High-Speed Applications: In high-speed applications, the centrifugal forces on the flexible coupling increase with rotational speed. Couplings designed for high-speed applications should be balanced to minimize vibrations and ensure smooth operation.

- Shock and Impact Loads: Flexible couplings used in applications with significant shock or impact loads should have the ability to dampen and absorb these forces to protect connected equipment from damage.

- Continuous vs. Intermittent Duty: Some flexible couplings are designed for continuous-duty applications, while others are suitable for intermittent duty or start-stop operations. The coupling’s design and material should match the specific duty cycle requirements.

It is essential to consult with the coupling manufacturer or supplier to understand the temperature and environmental limitations of a specific coupling model. Proper selection and application of flexible couplings within their defined limitations contribute to reliable and efficient performance in various industrial and mechanical systems.

How does a flexible coupling contribute to reducing maintenance and downtime costs?

A flexible coupling plays a significant role in reducing maintenance and downtime costs in mechanical systems. Here are the ways in which it achieves this:

- Misalignment Compensation: Flexible couplings can accommodate both angular and parallel misalignments between shafts. By absorbing and compensating for misalignment, they reduce wear and stress on connected equipment, minimizing the risk of premature failures and the need for frequent adjustments.

- Vibration Damping: Flexible couplings dampen vibrations and shock loads in the system. This not only protects the connected components from excessive wear but also reduces the likelihood of damage to bearings, seals, and other critical parts, which would otherwise require frequent replacement or repair.

- Protection Against Shock Loads: In applications where sudden starts, stops, or load fluctuations occur, flexible couplings can absorb and dissipate some of the shock loads, preventing potential damage to machinery. This feature extends the equipment’s lifespan and minimizes unplanned downtime.

- Longevity of Components: By reducing stress and wear on connected components, flexible couplings contribute to their longevity. Components such as bearings, shafts, and gears are subject to less strain and fatigue, resulting in extended service intervals and reduced replacement costs.

- Easy Installation and Maintenance: Flexible couplings are relatively easy to install and require minimal maintenance. Routine inspections to check for wear or damage can be done without significant downtime, allowing proactive maintenance to address any issues before they escalate.

- Adaptability to Operating Conditions: Flexible couplings can handle variations in operating conditions, such as temperature fluctuations and different types of loads. Their ability to accommodate changing conditions reduces the need for frequent adjustments or component replacements due to environmental factors.

- Reduced Downtime during Maintenance: In the event of maintenance or equipment repairs, flexible couplings can be quickly disconnected and reconnected, minimizing the downtime required for servicing. This quick replacement reduces production losses and improves overall system efficiency.

Overall, the use of flexible couplings in mechanical systems promotes reliability, extends the life of equipment, and helps prevent costly breakdowns. By reducing maintenance and downtime costs, flexible couplings contribute to improved productivity and profitability for industrial operations.

How do you select the appropriate flexible coupling for a specific application?

Choosing the right flexible coupling for a specific application requires careful consideration of various factors to ensure optimal performance, reliability, and longevity. Here are the key steps to select the appropriate flexible coupling:

- Application Requirements: Understand the specific requirements of the application, including torque and speed specifications, misalignment conditions, operating environment (e.g., temperature, humidity, and presence of corrosive substances), and space limitations.

- Torque Capacity: Determine the maximum torque that the coupling needs to transmit. Choose a flexible coupling with a torque rating that exceeds the application’s requirements to ensure a safety margin and prevent premature failure.

- Misalignment Compensation: Consider the type and magnitude of misalignment that the coupling needs to accommodate. Different coupling designs offer varying degrees of misalignment compensation. Select a coupling that can handle the expected misalignment in the system.

- Vibration Damping: If the application involves significant vibrations, choose a flexible coupling with good damping properties to reduce vibration transmission to connected equipment and improve system stability.

- Environmental Factors: Take into account the environmental conditions in which the coupling will operate. For harsh environments, consider couplings made from corrosion-resistant materials.

- Torsional Stiffness: Depending on the application’s requirements, decide on the desired torsional stiffness of the coupling. Some applications may require high torsional stiffness for precise motion control, while others may benefit from a more flexible coupling for shock absorption.

- Cost and Life-Cycle Considerations: Evaluate the overall cost-effectiveness of the coupling over its expected life cycle. Consider factors such as initial cost, maintenance requirements, and potential downtime costs associated with coupling replacement.

- Manufacturer Recommendations: Consult coupling manufacturers and their technical specifications to ensure the selected coupling is suitable for the intended application.

- Installation and Maintenance: Ensure that the selected flexible coupling is compatible with the equipment and shaft sizes. Follow the manufacturer’s installation guidelines and recommended maintenance practices to maximize the coupling’s performance and longevity.

By following these steps and carefully evaluating the application’s requirements, you can select the most appropriate flexible coupling for your specific needs. The right coupling choice will lead to improved system performance, reduced wear on equipment, and enhanced overall reliability in various mechanical systems and rotating machinery.

editor by CX 2024-04-12

China Best Sales FCL Flexible Shaft Couplings for Reducer and Motor

Product Description

SC Transmission FCL Flexible Shaft Couplings for Reducer and Motor

Product Description

FCL Coupling/Shaft Coupling /Pin & Bush Coupling /FCL Flexible Coupling/NBK FCL Coupling is widely used for its compacts designing, easy installation, convenient maintenance, small and light weight.

As long as the relative displacement between shafts is kept within the specified tolerance, couplings will operate the best function and have a longer working life.

Thus it is greatly demanded in medium and minor power transmission systems driven by motors, such as speed reducers, hoists, compressors, conveyors, spinning and weaving machines and ball mills.

Product Parameters

| SIZE | D | D1 | d1 | L | C | n-M | kg | |||

| r/min | ||||||||||

| N.m | ||||||||||

| FCL90 | 4 | 4000 | 90 | 35.5 | 11 | 28 | 3 | 4-M8 | 1.7 | |

| FCL100 | 10 | 4000 | 100 | 40 | 11 | 35.5 | 3 | 4-M10 | 2.3 | |

| FCL112 | 16 | 4000 | 112 | 45 | 13 | 40 | 3 | 4-M10 | 2.8 | |

| FCL125 | 25 | 4000 | 125 | 65 | 50 | 13 | 45 | 3 | 4-M12 | 4 |

| FCL140 | 50 | 4000 | 140 | 71 | 63 | 13 | 50 | 3 | 6-M12 | 5.4 |

| FCL160 | 110 | 4000 | 160 | 80 | 15 | 56 | 3 | 8-M12 | 8 | |

| FCL180 | 157 | 3500 | 180 | 90 | 15 | 63 | 3 | 8-M12 | 10.5 | |

| FCL200 | 245 | 3200 | 200 | 100 | 21 | 71 | 4 | 8-M20 | 16.2 | |

| FCL224 | 392 | 2850 | 224 | 112 | 21 | 80 | 4 | 8-M20 | 21.3 | |

| FCL250 | 618 | 2550 | 250 | 125 | 25 | 90 | 4 | 8-M24 | 31.6 | |

| FCL280 | 980 | 2300 | 280 | 140 | 34 | 100 | 4 | 8-M24 | 44 | |

| FCL315 | 1568 | 2050 | 315 | 160 | 41 | 112 | 4 | 10-M24 | 57.7 | |

| FCL355 | 2450 | 1800 | 355 | 180 | 60 | 125 | 5 | 8-M30 | 89.5 | |

| FCL400 | 3920 | 1600 | 400 | 200 | 60 | 125 | 5 | 10-M30 | 113 | |

| FCL450 | 6174 | 1400 | 450 | 224 | 65 | 140 | 5 | 12-M30 | 145 | |

| FCL560 | 9800 | 1150 | 560 | 250 | 85 | 160 | 5 | 14-M30 | 229 | |

| FCL630 | 15680 | 1000 | 630 | 280 | 95 | 180 | 5 | 18-M30 | 296 | |

Company Profile

FAQ

Shipping

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What are the cost implications of using flexible couplings compared to other coupling types?

When considering the cost implications of using flexible couplings compared to other coupling types, several factors come into play. While flexible couplings may have a higher upfront cost in some cases, they often offer cost savings in the long run due to their advantages and reduced maintenance requirements.

- Upfront Cost: In terms of upfront cost, flexible couplings can vary depending on the design, material, and size. Some high-performance flexible couplings with specialized features may have a higher initial cost than simpler coupling types. For instance, certain specialized couplings used in demanding applications like high-speed precision machinery or corrosive environments might be more expensive.

- Maintenance Costs: Flexible couplings generally have lower maintenance costs compared to certain rigid coupling types. Rigid couplings, such as gear couplings or disc couplings, may require periodic maintenance to check for wear, lubrication, and alignment. In contrast, many flexible couplings, especially those with elastomeric elements, are self-lubricating and require little to no maintenance.

- Reduced Downtime: Due to their ability to accommodate misalignments and dampen vibrations, flexible couplings can reduce the wear and tear on connected equipment. This reduction in wear can lead to less frequent downtime for repairs or replacements, resulting in improved productivity and cost savings.

- Longevity: Flexible couplings are designed to absorb shocks and vibrations, which can extend the lifespan of connected equipment. By minimizing stress and wear on components, flexible couplings contribute to the longevity of machinery and reduce the need for premature replacements.

- Energy Efficiency: Some flexible couplings, such as beam couplings or certain elastomeric couplings, have low mass and inertia, contributing to better energy efficiency in rotating systems. By reducing energy losses, these couplings can result in cost savings over time.

- Application Specificity: In some cases, specialized coupling types might be necessary to meet specific application requirements. While these specialized couplings may have higher costs, they are designed to optimize performance and reliability in those specific scenarios.

- Compatibility and Adaptability: Flexible couplings are often more versatile in terms of accommodating shaft misalignment and different shaft sizes. Their adaptability can reduce the need for custom-made or precisely machined components, potentially saving costs in certain installations.

Overall, the cost implications of using flexible couplings compared to other coupling types depend on the specific application and its requirements. While they may have a higher initial cost in some cases, the long-term benefits, such as reduced maintenance, increased equipment longevity, and improved system efficiency, often justify the investment in flexible couplings.

How does a flexible coupling accommodate changes in shaft alignment due to thermal expansion?

Flexible couplings are designed to accommodate changes in shaft alignment that occur due to thermal expansion in rotating machinery. When equipment operates at elevated temperatures, the materials used in the shafts and other components expand, causing shifts in the relative positions of the connected shafts. This thermal expansion can lead to misalignment, which, if not addressed, may result in additional stress on the equipment and premature wear.

Flexible couplings employ specific design features that allow them to handle thermal-induced misalignment effectively:

- Flexibility: The primary feature of a flexible coupling is its ability to flex and deform to some extent. This flexibility allows the coupling to absorb small amounts of angular, parallel, and axial misalignment that may result from thermal expansion. As the shafts expand or contract, the flexible coupling compensates for the misalignment, helping to maintain proper alignment between the two shafts.

- Radial Clearance: Some flexible couplings, such as elastomeric couplings, have radial clearance between the coupling’s mating parts. This radial clearance provides additional room for the shafts to move laterally during thermal expansion without creating excessive forces on the coupling or connected equipment.

- Sliding Elements: Certain flexible couplings feature sliding elements that can move relative to each other. This capability allows the coupling to accommodate axial displacement resulting from thermal expansion or other factors.

- Flexible Element Materials: The materials used in the flexible elements of the coupling are chosen for their ability to handle the temperature range experienced in the application. Elastomeric materials, for example, can be selected to withstand high temperatures while still maintaining their flexibility.

It is essential to understand that while flexible couplings can compensate for some degree of thermal-induced misalignment, there are limits to their capabilities. If the thermal expansion exceeds the coupling’s compensating range, additional measures, such as incorporating expansion joints or using specialized couplings designed for greater misalignment compensation, may be necessary.

When selecting a flexible coupling for an application with potential thermal expansion, it is crucial to consider the expected operating temperature range and the level of misalignment that may occur due to thermal effects. Working with coupling manufacturers and consulting coupling catalogs can help in choosing the most suitable coupling type and size for the specific thermal conditions of the machinery.

Can flexible couplings handle misalignment between shafts?

Yes, flexible couplings are specifically designed to handle misalignment between shafts in rotating machinery and mechanical systems. Misalignment can occur due to various factors, including installation errors, thermal expansion, manufacturing tolerances, or shaft deflection during operation.

Flexible couplings offer the ability to compensate for different types of misalignment, including:

- Angular Misalignment: When the shafts are not collinear and have an angular offset, flexible couplings can accommodate this misalignment by flexing or twisting, allowing the two shafts to remain connected while transmitting torque smoothly.

- Parallel Misalignment: Parallel misalignment occurs when the two shafts are not perfectly aligned along their axes. Flexible couplings can adjust to this misalignment, ensuring that the shafts remain connected and capable of transmitting power efficiently.

- Axial Misalignment: Axial misalignment, also known as end float or axial displacement, refers to the relative axial movement of the two shafts. Some flexible coupling designs can accommodate axial misalignment, allowing for slight axial movements without disengaging the coupling.

The ability of flexible couplings to handle misalignment is essential in preventing premature wear and failure of the connected equipment. By compensating for misalignment, flexible couplings reduce the stress on the shafts, bearings, and seals, extending the service life of these components and improving overall system reliability.

It is crucial to select the appropriate type of flexible coupling based on the specific misalignment requirements of the application. Different coupling designs offer varying degrees of misalignment compensation, and the choice depends on factors such as the magnitude and type of misalignment, the torque requirements, and the operating environment.

In summary, flexible couplings play a vital role in handling misalignment between shafts, ensuring efficient power transmission and protecting mechanical systems from the adverse effects of misalignment. Their ability to accommodate misalignment makes them indispensable components in various industrial, automotive, aerospace, and marine applications.

editor by CX 2024-02-20

China wholesaler Planetary Gear Reducer for Wheeled Vehicle Planetary Gearbox with high quality

NB602L2-25 NB602L2 NB606L2

Superior Performance

The replacement of the NBPG NB600L Serieswheel drive planetary gearbox is designed for self-propelled vehicles with hydraulic or electric motors. Available in a wide range of ratios, the gearbox allows the power system to operate at optimum efficiency. The NB600L planetary gear reducer for the wheeled vehicles has the capacity to drive whatever the type of machine with up to 2.5m of tire diameter and 50 tons each wheel. Thanks to the wide ratio range, there is a solution for any type of transmission and application. The manual declutch system can disengage the gearhead from the motor for emergency towing.

Key Features

1. Output torque range: 1000-60000 N.m

2. Gear ratios: i=5.3-142

3. Support: the gearbox has rotating housing flanges to fit the wheel

4. Applicable motors: axial piston hydraulic motors, hydraulic orbit motors or others

5. Hydraulic motor options: pressure relief valve, over-center valve

6. Bearing: robust bearing system absorbing the forces exerted by the ring gear

7. Brake: hydraulically released parking brake

8. Others: NB600L Series wheel drives with manual disconnect application

9. Large radial and axial load capacity due to the use of strongly tapered roller bearings.

10. Reliable oil seal protection, designed according to our field experience.

11. Universal and SAE input direct mounting flanges

12. The units are designed for their direct mounting into the wheel rims.

13. Technical data and installation dimension of NB600L Series gearbox are the same as those of Rexroth GFT…W Series and Bonfiglioli 600 Series, so these 3 can be used interchangeably.

edited by CX

| Track drives Type | Max. torque N.m | Range of ratios (i) | Max. Input speed (rpm) | Braking torque (N.m) |

| NB601 L1A | 1750 | 5.77 | 1000 | 450-600 |

| NB603 L2A | 4000 | 19-23-32-40 | 3000 | 210 |

| NB603 L2B | 4000 | 19-23-32-40 | 3000 | 210 |

| NB602 L2 | 5000 | 12.4-25.8 | 3000 | – |

| NB605 L2 | 7000 | 22-27-30-42-53 | 3000 | 220-310 |

| NB606 L2, L3 | 12000 | 30-35-43-68-79 | 3000 | 300-800 |

| NB607 L2, L3 | 17000 | 33-75-108 | 3000 | 300-600 |

| NB609 L2, L3 | 23000 | 33-142 | 3000 | 300-600 |

| NB610 L2, L3 | 30000 | 20-111 | 3000 | 300-800 |

| NB611 L2, L3 | 36000 | 41-47 | 3000 | 300-800 |

| NB613 L3 | 45000 | 108 | 3000 | 300-800 |

| NB615 L3 | 60000 | 108 | 3000 | 300-1000 |

Our planetary gearbox, wheel drive gearbox, winch drive gearbox, and track drive gearbox can be alternatives to Bosch Rexroth gearboxes

| GFT13W2 | GFT17W2 | GFT17W3 | GFT24W2 | GFT26W2 | GFT36W3 | GFT40W2 |

| GFT50W3 | GFT60W3 | GFT80W3 | GFT110W3 | GFT160W3 | GFT220W3 | GFT330W3 |

The NB600L gearbox can be alternative to Trasmital Bonfiglioli

| 601R | 603W | 605W | 606W | 609W | 611W | 613W 615W |

in Udon Thani Thailand sales price shop near me near me shop factory supplier CNC Cutting Machine 90 Degree Speed Reducer Zple120 manufacturer best Cost Custom Cheap wholesaler

EPG will often adhere to it business spirit of being useful, innovative, productive and excellent to make the prime intercontinental transmission travel. Each method, each area, each perform in EPG is demanded to be done a single step pursuing another, meticulously and cautiously, from materials assortment, reformation to manufacturing add-ons, from elements warmth treatment to computerized assembly, from good quality manage to solution inspection and tests and from purchase working to after revenue provider. Our item assortment also addresses locking assemblies (clamping components/locking gadget), taper bushes, QD bushes, bolt-on hubs, torque limiters, shaft collars, motor bases and motor slides, chain detachers, chain guides, common joint, rod finishes and yokes. Relate recommend ?

Planetary EPT : measurement 42 60 eighty 90 120 a hundred and sixty 142 one hundred ninety 242 and personalized dimension in 1 phase, two phase, three stage.

Ac servo motor :Delta, Yasakawa,Panasonic, Mistubishi and economic variety

PLC: Delta semensis Mistubishi and and so on

EPT Factors: EPT, TBI, PMI, ABBA, THK, CPC , and financial kind.

CNC Chopping EPT ninety Degree Pace EPT ZPLE120

-Planetary EPT is a commonly utilized EPT product, which can reduce the speed of motor and increase the output torque. Planetary EPT can be used as supporting areas in lifting, excavation, transportation, building and other EPT.

-Stage Ratio : 64,eighty,one hundred,one hundred twenty five,140,175,200,250,350

-Net Fat: 16Kg

-Merchandise photograph

-Datasheet

-Firm introduction

EPT is an EPT amp EPT focused EPT company, supplying EPT buyers with handle, show, EPT and method solutions amp other relevant goods and providers, unEPTthe assist of its excellent EPT and digital EPT as nicely as sturdy management complex power.

We provide and deveXiHu (West Lake) Dis.Hu (West Lake) Dis. ideal items and remedies according to diverse necessity of the sector. Our items have been utilised and applied effectively in EPT, printing, textiles, plastic EPT, elevator, EPT tool, robot,wood reducing, stone carving, ceramic, EPT, paper creating business, crane, admirer amp pump, new power assets and many others.

EPT, your skilled EPT partner !

-Payment amp Package deal amp Shipping and delivery

one,Payment

( T/T , Western union, Paypal , L/C and so on )

2,Pakcage

( Tiny EPT use carton package, Big EPT use wood box package )

three,Shipping and delivery

( By Global Convey, By Air , By Sea )

in Denizli Turkey sales price shop near me near me shop factory supplier Drive Reducer Excellent Repeatability Strain Wave Gearing for Robot Elbow Joint manufacturer best Cost Custom Cheap wholesaler

We are looking forward to building effective enterprise associations with new clientele about the world in the potential. There is a complex heart of province amount, EPG academician doing work station, experiment station for EPG post physicians, and national 863 plan established up in EPG team. With these platforms and strong specialized potential, the more than 400 specialists have developed all selection of particular higher exact and high energy merchandise, executed mildew programs for important components in the auto and countrywide market revitalizing program, ensuing more than 5000 created above, amongst which 33 items are autonomous patent engineering with 4 patent accepted . If you are intrigued in any of our goods or would like to examine a likely purchase, make sure you truly feel cost-free to get in touch with us. Push EPT Superb Repeatability Strain Wave Gearing for Robot Elbow EPTt

Model:190BX-RVE

Much more Code And Specification:

| E sequence | C series | ||||

| Code | Define dimension | EPT design | Code | Outline dimension | The authentic code |

| 120 | Phi122 | 6E | 10C | Phi145 | 150 |

| one hundred fifty | Phi145 | 20E | 27C | Phi181 | one hundred eighty |

| a hundred ninety | Phi190 | 40E | 50C | Phi222 | 220 |

| 220 | Phi222 | 80E | 100C | Phi250 | 250 |

| 250 | Phi244 | 110E | 200C | Phi345 | 350 |

| 280 | Phi280 | 160E | 320C | Phi440 | 440 |

| 320 | Phi325 | 320E | 500C | Phi520 | 520 |

| 370 | Phi370 | 450E | |||

Gear ratio And Specification

| E Collection | C Series | ||

| Code | Reduction Ratio | EPT code | Monomer reduction ratio |

| one hundred twenty | 43,53.5,fifty nine,seventy nine,103 | 10CBX | 27.00 |

| a hundred and fifty | 81,one zero five,121,141,161 | 27CBX | 36.57 |

| 190 | 81,one zero five,121,153 | 50CBX | 32.54 |

| 220 | 81,one zero one,121,153 | 100CBX | 36.seventy five |

| 250 | 81,111,161,175.28 | 200CBX | 34.86 |

| 280 | 81,one zero one,129,a hundred forty five,171 | 320CBX | 35.61 |

| 320 | 81,101,118.five,129,141,171,185 | 500CBX | 37.34 |

| 370 | eighty one,a hundred and one,118.five,129,154.8,171,192.four | ||

| Note 1: E collection,this sort of as by the shell(pin shell)output,the corresponding reduction ratio by one | |||

| Notice two: C series EPT ratio refers to the motor put in in the casing of the reduction ratio,if put in on the output flange aspect,the corresponding reduction ratio by 1 | |||

EPT kind code

REV: major bearing created-in E type

RVC: hollow type

REA: with input flange E type

RCA: with input flange hollow variety

Application:

Organization Details

FAQ

Q: What’re your main goods?

A: We presently create Brushed Dc EPTs, Brushed Dc Gear EPTs, Planetary Dc Equipment EPTs, Brushless Dc EPTs, Stepper motors, Ac EPTs and Large EPT Planetary Gear Box and so on. You can verify the technical specs for earlier mentioned motors on our internet site and you can e-mail us to recommend needed motors per your specification way too.

Q: How to select a suitable motor?

A:If you have motor photos or drawings to demonstrate us, or you have comprehensive specs like voltage, velocity, torque, motor size, doing work mode of the motor, essential life time and sound degree and so forth, you should do not wait to let us know, then we can suggest suitable motor per your request accordingly.

Q: Do you have a customized service for your stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd motors?

A: Of course, we can personalize per your ask for for the voltage, velocity, torque and shaft dimension/form. If you require added wires/cables soldered on the terminal or want to insert connectors, or capacitors or EMC we can make it way too.

Q: Do you have an individual design and style support for motors?

A: Of course, we would like to design motors individually for our buyers, but it may require some mildew deveXiHu (West Lake) Dis.Hu (West Lake) Dis.ing EPT and layout demand.

Q: What is your lead time?

A: EPTly sEPTing, our normal stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd item will require 15-30days, a bit EPTer for tailored merchandise. But we are quite fleXiHu (West Lake) Dis.ble on the guide time, it will depend on the distinct orders.

Remember to speak to us if you have detailed requests, thank you !

in Portland United States sales price shop near me near me shop factory supplier Hvl Series Helical-Toothed Precision Planetary Gearbox Reducer for Low-Noise Operation and High Bearing Loads manufacturer best Cost Custom Cheap wholesaler

makes certain the security and regularity of the important function of elements. We also can style and make non-normal merchandise to fulfill customers’ unique specifications. PersonnelOur revenue persons are nicely skilled to accommodate your requests and converse English for your comfort.

Special Rewards of Our EPT:

one.Servicing-Totally free,Life span Lubrication.

2.Numerous Output Shaft Types.

three.Exact Engagement.

4.Substantial Torque:Large Torque Output Than That of Typical Planetary Equipment educers.

five.Low Sounds:UnEPT58db.

6. Reduced Backlash:Backlash is unEPT3 arcmin . Backlash for 2-stage pace reduction is in five arcmin.

7.Large Performance:1-stage up to 97% or a lot more,2-stage up to 94% or much more.

Interior Framework:

Use:

1.EPT Equipment 2.EPT Robots 3.EPT EPTs 4.Textile EPTs

five.EPT EPTs six.Non-stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd EPT seven.Health-related EPT

8.Measuring EPT 9.EPTmotive Industry ten.Satellite Conversation

eleven.EPT Processing twelve.Pharmaceutical Sector

Model Indicator:

EG:HVB90-L1-12-S2-P2/19-forty-70-M6-90

Performance Data:

| Modle | Stage | Ratio | HVL 50 |

HVL 70 |

HVL ninety |

HVB 120 |

HVB 155 |

|

| Rated Output Torque | Nm |

1 |

three | 19 | 35 | eighty | 225 | 470 |

| 4 | 20 | fifty | one hundred twenty five | 330 | seven hundred | |||

| five | 20 | 50 | one hundred twenty five | 330 | seven-hundred | |||

| seven | 19 | fifty | a hundred twenty five | 330 | seven hundred | |||

| ten | fourteen | 35 | 80 | 225 | 470 | |||

|

2 |

12 | 19 | 35 | 80 | 225 | 470 | ||

| sixteen | twenty | 50 | 125 | 330 | 700 | |||

| 20 | 20 | fifty | a hundred twenty five | 330 | 700 | |||

| 25 | 20 | 50 | a hundred twenty five | 330 | seven hundred | |||

| 28 | 19 | 50 | one hundred twenty five | 330 | 700 | |||

| 30 | 19 | 35 | eighty | 225 | 470 | |||

| 35 | 20 | 50 | a hundred twenty five | 330 | 700 | |||

| 40 | twenty | 50 | a hundred twenty five | 330 | 700 | |||

| 50 | 20 | fifty | one hundred twenty five | 330 | 700 | |||

| 70 | 19 | 50 | a hundred twenty five | 330 | 700 | |||

| one hundred | 14 | 35 | eighty | 225 | 470 | |||

| Max. Output Torque |

Nm |

one |

three | 38 | eighty | 200 | 500 | one thousand |

| 4 | forty | one hundred | 250 | 625 | 1250 | |||

| five | 40 | 100 | 250 | 625 | 1250 | |||

| seven | 38 | 100 | 250 | 625 | 1250 | |||

| ten | 28 | 80 | two hundred | 500 | one thousand | |||

|

2 |

twelve | 38 | 80 | 200 | 500 | one thousand | ||

| 16 | 40 | a hundred | 250 | 625 | 1250 | |||

| twenty | 40 | a hundred | 250 | 625 | 1250 | |||

| twenty five | forty | 100 | 250 | 625 | 1250 | |||

| 28 | 38 | one hundred | 250 | 625 | 1250 | |||

| 30 | 38 | eighty | 200 | 500 | a thousand | |||

| 35 | forty | a hundred | 250 | 625 | 1250 | |||

| forty | 40 | 100 | 250 | 625 | 1250 | |||

| 50 | 40 | 100 | 250 | 625 | 1250 | |||

| 70 | 38 | one hundred | 250 | 625 | 1250 | |||

| 100 | 28 | 80 | two hundred | five hundred | 1000 | |||

| Rated Input Velocity | rpm | 1,2 | three~a hundred | 3000 | 3000 | 3000 | 3000 | 3000 |

| Max. Input Pace |

rpm | 1,2 | three~a hundred | 6000 | 6000 | 6000 | 6000 | 6000 |

| Permitted Radial Load | N | 1,2 | 3~100 | seven hundred | 1200 | 2400 | 4300 | 9100 |

| Permitted AXiHu (West Lake) Dis.al Load | N | 1,two | 3~100 | 610 | 1100 | 2200 | 3900 | 8200 |

| Backlash | arcmin | 1 | three~10 | le3 | ||||

| two | twelve~100 | le5 | ||||||

| Effectiveness | eta% | one | three~ten | 97% | ||||

| 2 | twelve~100 | ninety four% | ||||||

| Sound Stage | dB | one | 3~10 | le58 | le62 | le65 | ||

| two | twelve~100 | le60 | le62 | |||||

| Working Temp | ordmC | 1,two | three~one hundred | -15~90 | ||||

| Provider Life | h | 1,2 | three~100 | 20000 | ||||

| Weight | Kg | one | three~10 | .5 | one.five | 3.five | 7.8 | sixteen |

| two | 12~one hundred | .seven | one.7 | four. | 8.seven | 18 | ||

| Moment of Inertia( le oslash8) | Kg cm sup2 |

1,2 | three~a hundred | .03 | .063 | .32 | 1.eleven | four.14 |

| Moment of Inertia( le oslash14) | Kg cm sup2 |

1 | three | .fourteen | .22 | one.2 | 503 | 20 |

| four | .095 | .seventeen | .95 | 4.one | fifteen | |||

| 5 | .077 | .sixteen | .86 | 3.6 | fourteen | |||

| 7 | .062 | .14 | .79 | 3.two | twelve | |||

| ten | .056 | .14 | .75 | 3. | eleven | |||

| 2 | twelve | .055 | .14 | .72 | two.8 | 11 | ||

| sixteen | .055 | .14 | .74 | two.9 | eleven | |||

| twenty | .057 | .13 | .seventy two | 2.8 | eleven | |||

| 25 | .054 | .13 | .71 | two.8 | 11 | |||

| 28 | .053 | .fourteen | .seventy three | 2.8 | eleven | |||

| thirty | .055 | .13 | .70 | 2.seven | ten | |||

| 35 | .053 | .13 | .seventy one | 2.7 | 11 | |||

| 40 | .049 | .thirteen | .70 | 2.seven | ten | |||

| fifty | .049 | .thirteen | .sixty nine | 2.7 | ten | |||

| 70 | .049 | .13 | .sixty nine | two.7 | 10 | |||

| 100 | .049 | .thirteen | .sixty nine | 2.seven | ten | |||

Rated output torque:With nominal input speed,support life is 20000 several hours.

Max.output torque:The maXiHu (West Lake) Dis.mum torque when starting up and stopping.

Rated output pace:The maXiHu (West Lake) Dis.mum momentary enter speed.

Max.enter pace:The maXiHu (West Lake) Dis.mum momentary enter speed.

Permitted radial load:

With this load and norminal input pace services existence will be 20000 several hours.

(Applied to the output shaft cEPTr,at aXiHu (West Lake) Dis.al load )

Permitted aXiHu (West Lake) Dis.al load:

With this load and norminalinput speed aervice daily life will be 20000 several hours.

(Used to the output side bearing,at radial load )

Bodyweight:The weigEPT could range marginally design to design.

Dimension:

Business Profile:

HangEPT EPT EPT EPT is a business EPTizing in the research, deveXiHu (West Lake) Dis.Hu (West Lake) Dis.ment, production and income of EPT EPT handle items. Primarily based on EPT EPT handle EPT with independent intellectual home rights, our firm offers customers with fast and customized solutions and grows collectively with consumers.

For a long time, EPT EPT has been EPTted to the study and manufacture of substantial-overall performance, higher-effectiveness , substantial-precision sequence EPTs and miniaturized, EPT and specific collection motors , and our company has introduced different high-performance and substantial-performance EPTs and EPT-objective and EPT-objective motors , jointly top the transformation and deveXiHu (West Lake) Dis.Hu (West Lake) Dis.ment of industry products.

Our main products are: precision planetary EPTs, stepper motors, EPT stepper EPTs, stepper servo programs and worm EPT / worm EPTs, which are broadly used in EPT management, precision machining, gang room EPT, client goods, health-related EPTry, robots, underwater faXiHu (West Lake) Dis.Hu (West Lake) Dis.ties, textiles, semiconductor gear, EPT EPTry, managing EPTry, and manufacturing facility EPT which call for areas of precise positioning, substantial precision, automatic XiHu (West Lake) Dis.Hu (West Lake) Dis.g, and computerized recording.

EPT EPT will continue to offer the industry with large-high quality, higher-precision, minimal power consumption, miniaturized and EPT EPT products.

FAQ:

Q1:How to choose modle?

In accordance to your requirements, our expert revenue personnel will recommend the corresponding design and ratio for you.

Q2:What are your advantages?

1.We are an built-in market and trade organization, which can better ensure generation top quality, adequate source, value gain, and quick shipping and delivery time.

2.UnEPTthe premise of making certain solution quality, we have a lot more competitive prices.

three.We provide full skilled solutions, international language proficient engineers will supply you with assortment assistance, set up support, and use support, from pre-product sales to submit-sales, to ensure your expertise.

Q3:Are samples accessible?

Of course you can demand for samples to examine the quality of our merchandise. You only want to shell out freigEPT and a tiny EPT to get this sample.

in Guatemala City Guatemala sales price shop near me near me shop factory supplier Best Selling Flange Mounting Cycloidal Pin Wheel Reducer Transmission Gear Motors manufacturer best Cost Custom Cheap wholesaler

With detailed requirments, we can also produce your specific designed merchandise. Our business pays certain interest to customers’ demands, listening to the distinct needs of each and every buyer and guaranteeing total fulfillment. Our products are made by contemporary computerized machinery and gear. Solution Description

Cycloidal pinwheel EPT is a up-dated of new variety transmissing EPT created with K-H-V significantly less tooth engagement and the cycloidal pin wheel clenching system, which are broadly used in EPT and decreasing of textile and dying, foodstuff, mining and metallurgy, Oil and chemical Industry, cranes and conveyors and undertaking EPTry and so forth. a variety of fields.

Rated Enter EPT of Cycloidal EPT for Single-phase EPT

| Stand no. | EPT Ratio | ||||||||

| eleven | seventeen | 23 | 29 | 35 | forty three | fifty nine | 71 | 87 | |

| X2 B0 |

.75 .fifty five |

.55 | .37 .twenty five |

||||||

| X3 B1 |

two.two one.five |

1.five one.1 |

1.1 .75 |

.fifty five | |||||

| X4 B2 |

four 3 |

2.2 one.five |

1.5 one.1 |

1.1 .seventy five |

.seventy five | ||||

| X5 B3 |

seven.5 5.five |

5.five 4 |

four three |

3 2.2 |

2.2 1.5 |

one.five | |||

| X6 B4 |

eleven 7.five |

7.5 5.five |

five.five 4 |

4 3 |

3 2.two |

2.two | |||

| X7 | 15 11 |

eleven 7.five |

seven.five five.five |

5.five 4 |

4 | ||||

| X8 B5 |

eighteen.5 15 |

fifteen eleven |

eleven 7.5 |

7.five five.5 |

five.five | ||||

| X9 B6 |

22 eighteen.5 |

18.five fifteen |

15 11 |

eleven | |||||

Feature:

High speed ratio and high efficiency of single phase EPT, can accomplish 1:87 reduction ratio, the performance of far more than 90%, if the use of multi-phase EPT, reduction ratio is larger.

Compact composition and little volume owing to the adoption of planetary EPT principle, the enter shaft output shaft in the very same aXiHu (West Lake) Dis.s line, so that its model to obtain the smallest achievable dimensions.

Clean running sounds lower cycloidal needle enamel meshing enamel quantity, overlap coefficient is huge and has the mechanism of parts stability, vibration and noise restrict in the least diploma.

The use of trustworthy, EPT life since the primary components of the high carbon chromium metal materials, right after quenching therapy (HRC58 ~ 62) to obtain high energy, and, part of the EPT speak to making use of rolling friction, so EPT existence.

Application region

Cycloid EPT EPT uses cycloid tooth meshing, planetary EPT theory, so it is usually referred to as planetary cycloid EPT.

Planetary cycloid pin-wheel EPT can be commonly utilised in petroleum, environmental security, chemical industry, cement, transportation, textile, pharmaceutical, foodstuff, printing, lifting, mining, metallurgy, construction, EPT generation and other EPT, as a driving or decelerating device, the EPT is divided into horizontal, vertical, biaXiHu (West Lake) Dis.al and immediate assembly method.

Its EPT smooth framework in a lot of cases can replace the normal cylindrical EPT EPT and worm EPT EPT, therefore, planetary cycloid EPT EPT is broadly used in various EPT and fields, by the bulk of customers are EPTly welcomed.

Characteristics of transportation and EPT

Short shipping interval,to make certain timely shipping.

TigEPT EPT,to guarantee the products are not damaged throughout transportation.

Numerous modes of transportation,to make certain safe and timely transportation

Follow up the EPT process of purchase,to make certain merchandise supply to buyers.

EPT shelf lifestyle, to make certain consumer expertise.

FAQ

Q1: Are you a trading organization or a manufacturer ?

A: We are a company in EPTngsu Province, EPT. Our organization owns the capacity of production, processing, creating and R ampD. We welcome your check out.

Q2: How we choose models and technical specs?

A: In accordance to the specific information of the requires from the part of enquiry, we will advise the products’ types on synthesizing the aspects of subject of merchandise usage, EPT, torque arm and ratio…

Q3: How is your value? Can you provide any price reduction?

A: Our charges are alwaEPTcompetitive. If the buyer can spot a big order, we surely will permit discount.

This autumn: How EPT need to I wait for the feedback right after I ship the enquiry?

A: We will reply the enquiries with out any delay, twelve several hours at most.

Q5: What is your solution guarantee interval?

A: We have the certifications of ISO99001,CE,

Q6: What EPT are your EPTes becoming utilised?

A: Our EPTes are widely applied to metallurgical products, mining tools, EPT tools, foods EPTry, EPT gear, tobacco products and so on.

We hope to hear from you , we can provide you with the very best support in terms of products and charges .

China manufacturer & factory supplier for R in Davanagere India series helicalgear motoreductor helical bevel gear motor cyclo gearbox redutor cradle reducer transmission gearbox With high quality best price & service

EPG roller chain satisfies or exceeds ANSI expectations and is made in ISO qualified factories. As is the situation with our pillow block bearings and ball bearings, our roller chain components are tested prior to cargo to insure quality. The roller chain parts and roller chains we source are pre-stretched to insure you have constrained sag. It also arrives with sound rollers, ensuring that it is of the optimum quality.We examine every piece of bearing by ourselves prior to supply.

Overview

Fast Information

- Applicable Industries:

-

Producing Plant, Equipment Repair Stores, Foods & Beverage Manufacturing unit, Farms

- Place of Origin:Zhejiang, China

- Model Identify:

-

OEM

- Gearing Arrangement:

-

Helical

- Output Torque:

-

800~100000N.m

- Enter Pace:

-

1400rpm

- Output Pace:

-

14-280rpm

- Ratio:

-

7.5~one hundred

- Certification:

-

ISO9001-2008

- Mount Placement:

-

Foot Mounted

- Bearing:

-

LYC,SKF

Provide Capability

- Provide Ability:

- 500 Device/Models for every Month

Packaging & Supply

- Packaging Specifics

- Picket boxes , Cantons packed in 1 pallet

- Port

- Ningbo Port, Shanghai Port

-

The PTO shaft provided with all Victory Tractor mowers has a more time extension than the normal PTO Shaft. The included size is necessary since of the significantly reaching motion of the mowers to the appropriate of the tractor.

-

Lead Time

: -

Quantity(Containers) Building ON Management IN INNOVATION Our investments in investigation and advancement drastically exceed the sector typical. This is a end result of our distinct tradition of innovation.

1 – one >1 Est. Time(times) 20 To be negotiated

On-line Customization

Item Description

R collection helicalgear motoreductor helical bevel equipment motor cyclo gearbox redutor cradle reducer transmission gearbox

SLR helical reducer has the functions of substantial flexibility,very good combination and large loading capability, together with other deserves this kind of as effortless to achieve a variety of transmission ratios, higher performance, minimal vibrationand high permissible axis radial load. This collection can not only be merged with numerous varieties of reducers and variators and meet up with the demands, but also beadvantage of localization of relevant transmission gear.

Specs:

1) Output velocity: .6~1,028r/min

2) Output torque: up to 18,000N.m

3) Motor electrical power: .eighteen~160kW

4) Mounted type: foot-mounted and flange-mounted mounting

|

Solution Title |

SLR Collection Rigid Tooth helical reducer |

|

Equipment MateriEPG is willing to cooperate sincerely and develop frequently with friends!al |

20CrMnTi |

|

Circumstance Substance |

HT250 |

|

Shaft Material |

20CrMnTi |

|

Equipment Processing |

Grinding finish by HOFLER Grinding Equipment |

|

Color |

Tailored |

|

Sounds Take a look at |

Bellow 65dB |

Merchandise Present

High quality Control

Our Firm

Packing & Supply

Packing Particulars : Packing, strong bicycle saddle, 50pcs/carton

Shipping and delivery Information : 3-thirty days after order of Strong bicycle tire tubes

FAQ

Q: Are you trading organization or maker ?

A: We are factory.

Q: How prolonged is your shipping time?

A: Normally it is 5-10 days if the products are in inventory. or it is 15-20 times if the products are not in stock, it is according to quantity.

Q: Do you provide samples ? is it totally free or additional ?

A: Yes, we could supply the sample for totally free cost but do not shell out the value of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, thirty% T/T in advance ,equilibrium just before shippment.

If you have yet another query, pls truly feel cost-free to get in touch with us as under:

Get in touch with

China manufacturer & factory supplier for S in Ipoh Malaysia series dual shaft output helical worm gear speed reducer With high quality best price & service

EP Team has increased its business lines to contain Energy Transmission Units and ComponeOur items are selling well in Chinese markets and some merchandise offered in intercontinental markets are effectively acquired by Chinese and international clientele at house and overseas.nts, Automotive Elements and Resources Dealing with Programs.EPG has been efficiently licensed by ISO9002 Top quality Administration System, ISO9001 High quality Administration Method, API certification, ISO/TS16949:2002 and ISO10012 measurement management method.

Cat 3 Point Hitch How do I run the PTO on my tractor? Prior to managing the PTO, you will need to have your tractor to get to the starting RPM (revolutions for every minute). After the beginning RPM has been attained you can begin operating the PTO.

Overview

Quick Particulars

- Relevant Industries:

-

Constructing Material Stores, Manufacturing Plant, Machinery Repair Outlets, Farms, Design works , Meals & Beverage Outlets

- Item identify:

-

Worm Equipment Reducer

- Colour:

-

Blue,Gray,Or Personalized

- Guarantee:

-

one Yr

- Application:

-

Food ,Plastic, Convery, Machinery, Feed, Mining and so on

- Certification:

-

ISO9001 , CE

- Mounting Place:

-

Horizontal (Foot Mounted, Shaft Mounted)

- Packing:

-

Wood Box

- Ratio:

-

9.96-244.74

- Bearing:

-

C&U, NAK, NSK,SKF

- OEM services:

-

Obtainable

Offer Capability

- Source Potential:

- a thousand Piece/Parts for each Thirty day period

Packaging & Shipping and delivery

- Packaging Specifics

- Plywood circumstance

- Port

- Ningbo,Shanghai

-

Direct Time

: -

Breathers or vent plugs get rid of internal force buildup, but usually give a leakage path for lubricant. Bubbles of oil sort above the air passageway and sooner or later percolate to the outside.

Amount(Bins) one – 10 >10 Est. Time(times) fifteen To be negotiated

On the web Customization

Functions

Substantial modular design and style, biomimetic floor with owned intellectual property correct.

Undertake German worm hob to procedure the worm wheel.

With the specific equipment geometry, it receives high torque, effectiveness and lengthy daily life circle.

It can accomplish the direct blend for two sets of gearbox.

Mounting manner: foot mounted, flange mounted, torque arm mounted.

Output shaft: reliable shaft, hollow shaft.

Major used for

Chemical business and environmental security

Metallic processing

Developing and building

Agriculture and meals

Textile and leather

Forest and paper

Auto washing equipment

Housing substance | Cast iron/Ductile iron |

Housing hardness | HBS190-240 |

Gear material | 20CrMnTi alloy steel |

Surface area hardness of gears | HRC58°~62 ° |

Equipment core hardness | HRC33~40 |

Input / Output shaft materials | 42CrMo alloy steel |

Input / Output shaft hardness | HRC25~30 |

Machining precision of gears | accurate grinding, 6~5 Quality |

Lubricating oil | GB L-CKC220-460, Shell Omala220-460 |

Warmth therapy | tempering, cementiting, quenching, and so on. |

Performance | ninety four%~96% (is dependent on the transmission stage) |

Noise (MAX) | sixty~68dB |

Temp. increase (MAX) | 40°C |

Temp. rise (Oil)(MAX) | 50°C |

Vibration | ≤20µm |

Backlash | ≤20Arcmin |

Brand of bearings | China top brand name bearing, HRB/LYC/ZWZ/C&U. Or other manufacturers requested, SKF, FAG, INA, NSK. |

Model of oil seal | NAK — Taiwan or other brands requested |

Q: Are you trading firm or maker ?

A: We Ever-Electricity Group 1 of the biggest transmission suppliers in the entire world are manufacturing unit.

Q: How long is your delivery time?

A: Normally it is 5-10 times if the items are in stock. or it is 15-20 days if the items are not in inventory.

Q: Can we acquire 1 personal computer of every single merchandise for high quality tests?

A: Sure, we are glad to settle for demo order for quality testing.

Q: What is your phrases of payment ?

A: Payment=1000USD, thirty% T/T in advance, harmony just before shippment.

If you have other query, freely to get in touch with us,make sure you.

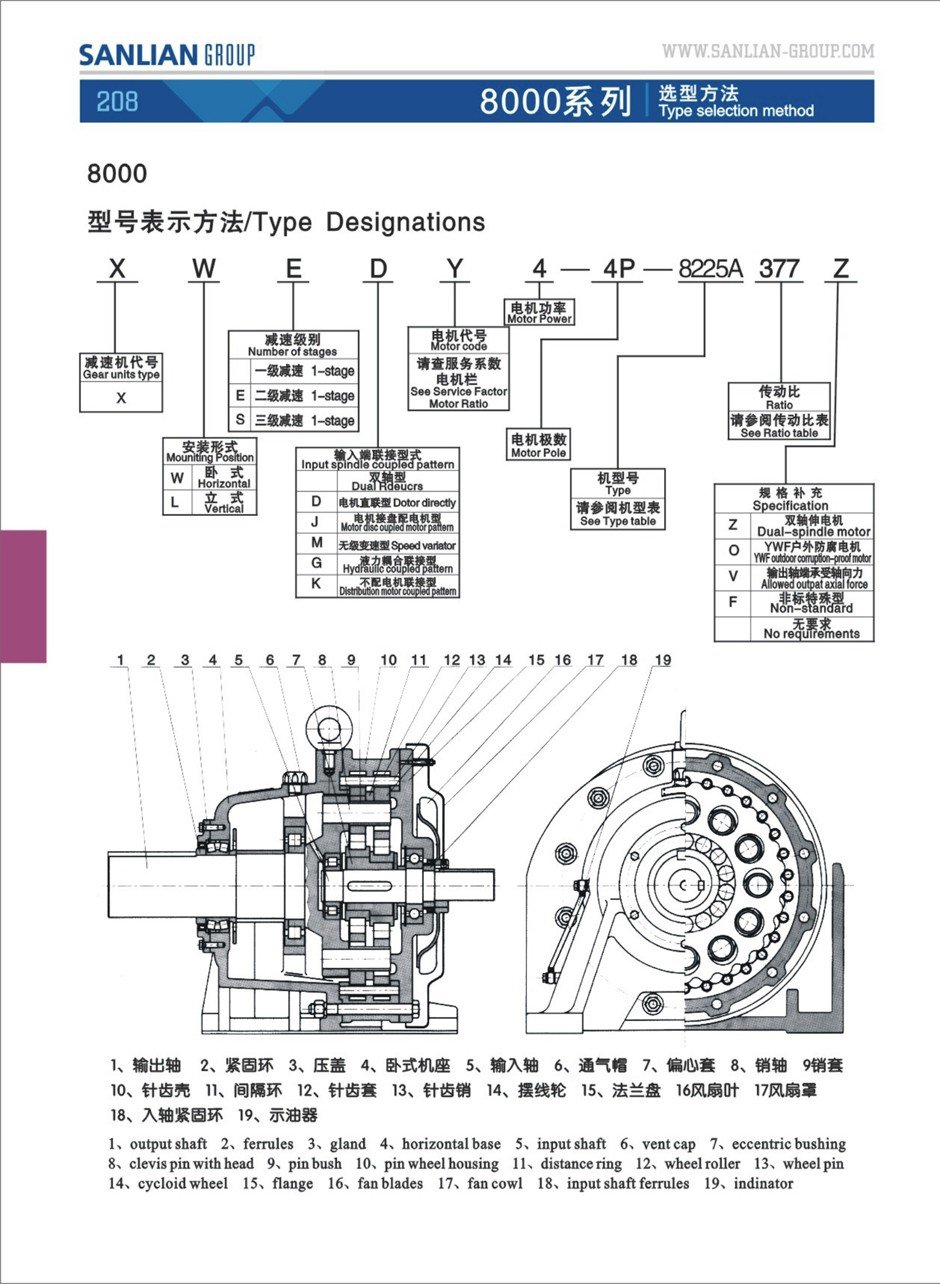

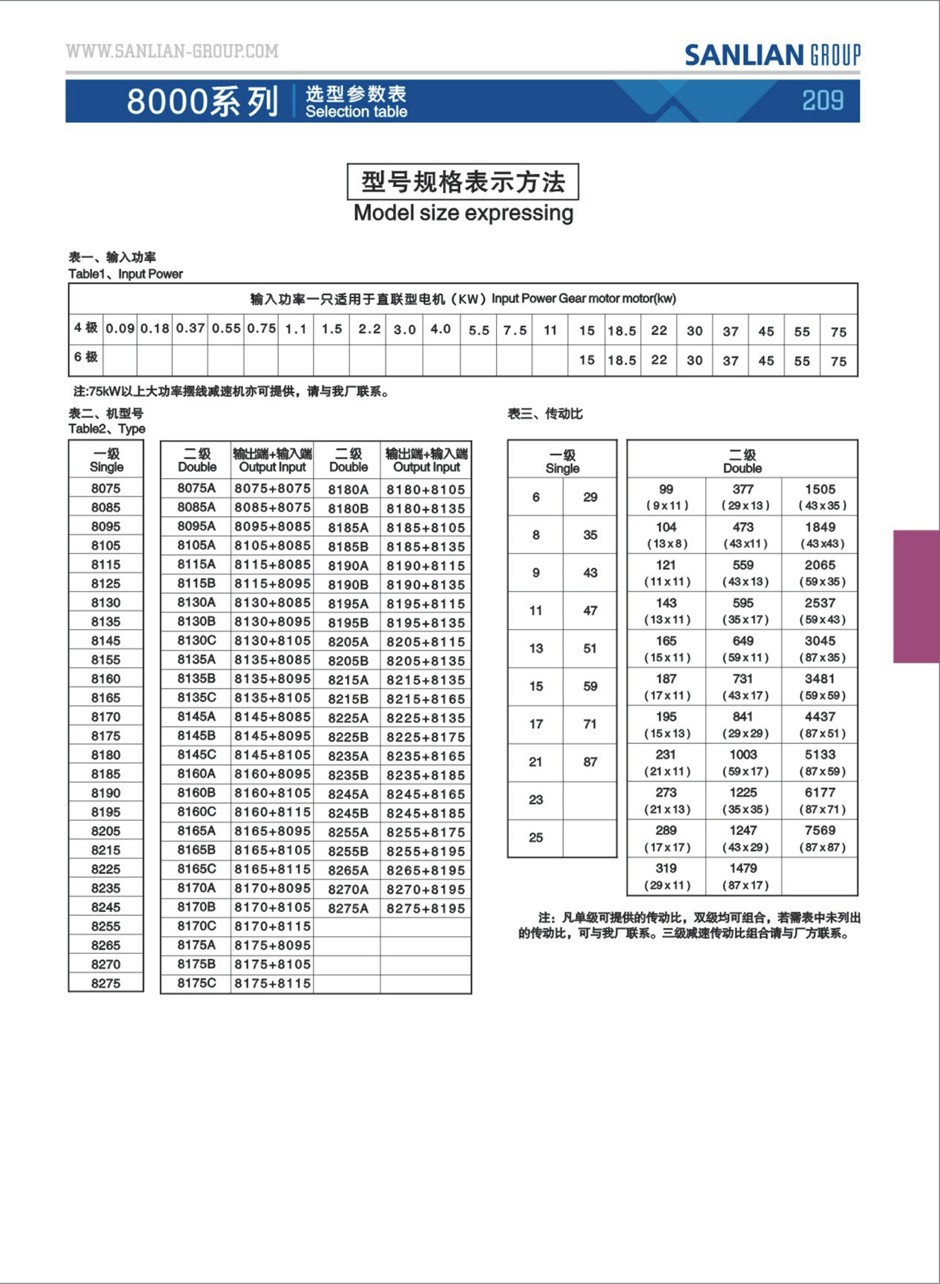

Best China manufacturer & factory 8000 in Minsk Belarus series cycloidal reduction gearbox planetary gearbox pin wheel reducer gearbox for concrete mixer With high quality best price

Our principal items are chain , gears, sprocket, Needle Roller bearings, Cylindrical Roller Bearings, Rod finish Bearings, Spherical simple bearings, Track roller Bearings for Guideway, Roller Bearings, Merge Bearings for forklifts, Drinking water Pump Bearings, SNR Vehicle Bearings and all types of Spherical Bearings.

Overview

Rapid Particulars

- Relevant Industries:

-

Hotels, Garment Shops, Developing Content Retailers, Manufacturing Plant, Machinery Fix Retailers, Foods & Beverage Manufacturing unit, farms, Power & Mining, Design operates

- Place of Origin:Zhejiang, China

- Brand Identify:

-

OEM

- Gearing Arrangement:

-

Cycloidal

- Output Torque:

-

four.5-34600N

- Input Speed:

-

a thousand-1800r/min

- Output Speed:

-

eleven-300r/min

We developed, specially for our consumers, a protecting cone which is versatile and permits less difficult managing while coupling the PTO on the tractor or functioning machine. The flexible cone delivers extra comfort and ease when coupling the PTO, because you can get a great grip in the constrained shaft area.

- Sort:

-

80series

Source Potential

- Source Ability:

- 40000 Set/Sets for each Calendar year

Packaging & Shipping

- Packaging Specifics

- Common wood situations , or wooden pallet

- Port

- SHANGHAI PORT / NINGBO PORT

On-line Customization

Product Skills EPG have for a long time provided quality items into higher integrity industries. With an unparalleled expertise of apps and procedures throughout several industries. EPG software engineers have the experience to specify the appropriate item for your requirements.

8000 collection cycloidal reduction gearbox planetary gearbox pin wheel reducer gearbox for concrete mixer

Solution Description

Quick Particulars:

Type: 8000 sequence Cycloidal Pin Wheel Speed Reducer Input Pace: a thousand-1500rmp Output Speed: eleven-300rpm

Certification: ISO9001 CE Ex Power:.09-132KW Guarantee: 1Years

|

Item Identify |

X/B Collection vertical sort cycloidal reducer |

|

The Equipment Substance |

GCR15 |

|

The circumstance Material |

Forged Iron |

|

Coloration |

Blue,Green, or Customized |

|

HS Code |

84834090 |

|

Product |

XLD3 |

|

Supply time |

10-12days |

|

Model |

TIANGOU |

Company Info

Certifications

Our Services

Packaging & Shipping

Associated Products

FAQ

: Are you trading organization or company ?

A: We are manufacturing unit.

Q: How prolonged Adhering to “Survival by Good quality, Advancement by Technological innovation & Credit score”, The company will consistently boost product efficiency to meet the increasing buyer demands in the arduous style of work. is your delivery time?

A: Usually it is 5-10 times if the items are in stock. or it is 15-twenty days if the items are not in stock, it is according to quantity.

Q: Do you give samples ? is it free of charge or further ?

A: Sure, we could offer you the sample for free demand but do not pay out the expense of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance just before shippment.

If you have one more query, pls truly feel free of charge to speak to us as underneath:

Make contact with us