Product Description

Stainless Steel Coupling Gear Rigid Roller Chain Fluid Tyre Grid Jaw Spider HRC Nm Motor Flange Gear Pump Rubber Spline Shaft Flexible Universal Joint Coupling

Product Description

Main products

Coupling refers to a device that connects 2 shafts or shafts and rotating parts, rotates together during the transmission of motion and power, and does not disengage under normal conditions. Sometimes it is also used as a safety device to prevent the connected parts from bearing excessive load, which plays the role of overload protection.

Couplings can be divided into rigid couplings and flexible couplings.

Rigid couplings do not have buffering property and the ability to compensate the relative displacement of 2 axes. It is required that the 2 axes be strictly aligned. However, such couplings are simple in structure, low in manufacturing cost, convenient in assembly and disassembly, and maintenance, which can ensure that the 2 axes are relatively neutral, have large transmission torque, and are widely used. Commonly used are flange coupling, sleeve coupling and jacket coupling.

Flexible coupling can also be divided into flexible coupling without elastic element and flexible coupling with elastic element. The former type only has the ability to compensate the relative displacement of 2 axes, but cannot cushion and reduce vibration. Common types include slider coupling, gear coupling, universal coupling and chain coupling; The latter type contains elastic elements. In addition to the ability to compensate the relative displacement of 2 axes, it also has the functions of buffering and vibration reduction. However, due to the strength of elastic elements, the transmitted torque is generally inferior to that of flexible couplings without elastic elements. Common types include elastic sleeve pin couplings, elastic pin couplings, quincunx couplings, tire type couplings, serpentine spring couplings, spring couplings, etc

Coupling performance

1) Mobility. The movability of the coupling refers to the ability to compensate the relative displacement of 2 rotating components. Factors such as manufacturing and installation errors between connected components, temperature changes during operation and deformation under load all put CHINAMFG requirements for mobility. The movable performance compensates or alleviates the additional load between shafts, bearings, couplings and other components caused by the relative displacement between rotating components.

(2) Buffering. For the occasions where the load is often started or the working load changes, the coupling shall be equipped with elastic elements that play the role of cushioning and vibration reduction to protect the prime mover and the working machine from little or no damage.

(3) Safe, reliable, with sufficient strength and service life.

(4) Simple structure, easy to assemble, disassemble and maintain.

How to select the appropriate coupling type

The following items should be considered when selecting the coupling type.

1. The size and nature of the required transmission torque, the requirements for buffering and damping functions, and whether resonance may occur.

2. The relative displacement of the axes of the 2 shafts is caused by manufacturing and assembly errors, shaft load and thermal expansion deformation, and relative movement between components.

3. Permissible overall dimensions and installation methods, and necessary operating space for assembly, adjustment and maintenance. For large couplings, they should be able to be disassembled without axial movement of the shaft.

In addition, the working environment, service life, lubrication, sealing, economy and other conditions should also be considered, and a suitable coupling type should be selected by referring to the characteristics of various couplings.

If you cannot determine the type, you can contact our professional engineer

Related products

Company Profile

Our Equipments

Main production equipment:

Large lathe, surface grinder, milling machine, gear shaper, spline milling machine, horizontal broaching machine, gear hobbing machine, shaper, slotting machine, bench drilling machine, radial drilling machine, boring machine, band sawing machine, horizontal lathe, end milling machine, crankshaft grinder, CNC milling machine, casting equipment, etc.

Inspection equipment:

Dynamic balance tester, high-speed intelligent carbon and sulfur analyzer, Blochon optical hardness tester, Leeb hardness tester, magnetic yoke flaw detector, special detection, modular fixture (self-made), etc.

Machining equipments

Heat equipment

Our Factory

Application – Photos from our partner customers

Company Profile

Our leading products are mechanical transmission basic parts – couplings, mainly including universal couplings, drum gear couplings, elastic couplings and other 3 categories of more than 30 series of varieties. It is widely used in metallurgical steel rolling, wind power, hydropower, mining, engineering machinery, petrochemical, lifting, paper making, rubber, rail transit, shipbuilding and marine engineering and other industries.

Our factory takes the basic parts of national standards as the benchmark, has more than 40 years of coupling production experience, takes “scientific management, pioneering and innovation, ensuring quality and customer satisfaction” as the quality policy, and aims to continuously provide users with satisfactory products and services. The production is guided by reasonable process, and the ISO9001:2015 quality management system standard is strictly implemented. We adhere to the principle of continuous improvement and innovation of coupling products. In recent years, it has successfully developed 10 national patent products such as SWF cross shaft universal coupling, among which the double cross shaft universal joint has won the national invention patent, SWF cross shaft universal coupling has won the new product award of China’s general mechanical parts coupling industry and the ZHangZhoug Province new product science and technology project.

Our factory has strong technical force, excellent process equipment, complete professional production equipment, perfect detection means, excellent after-sales service, various products and complete specifications. At the same time, we can provide the design and manufacturing of special non-standard products according to the needs of users. Our products sell well at home and abroad, and are trusted by the majority of users. We sincerely welcome friends from all walks of life at home and abroad to visit and negotiate for common development.p

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What are the torque and speed ratings for different sizes of flexible couplings?

The torque and speed ratings of flexible couplings can vary depending on their size, design, and material. Manufacturers typically provide specifications for each specific coupling model to ensure it is suitable for the intended application. Below are some general considerations regarding torque and speed ratings for different sizes of flexible couplings:

Torque Ratings:

The torque rating of a flexible coupling is the maximum amount of torque it can reliably transmit without experiencing excessive deformation or failure. It is essential to choose a coupling with a torque rating that exceeds the torque requirements of the application to ensure proper operation and avoid premature wear. Torque ratings are typically specified in Nm (Newton-meters) or lb-ft (pound-feet).

The torque capacity of a flexible coupling can increase with its size and design. Larger couplings, which have more substantial components and a larger flexible element, often have higher torque ratings compared to smaller couplings. Additionally, couplings with a more robust design, such as metallic couplings, generally have higher torque capacities compared to elastomeric couplings.

Speed Ratings:

The speed rating of a flexible coupling is the maximum rotational speed it can withstand while maintaining its structural integrity and performance. It is critical to select a coupling with a speed rating suitable for the application’s operating speed to avoid excessive wear and potential coupling failure. Speed ratings are typically specified in revolutions per minute (RPM).

Like torque ratings, the speed rating of a flexible coupling can be influenced by its size, design, and material. Larger couplings with more robust construction can often handle higher rotational speeds compared to smaller couplings. Metallic couplings, with their stiffer and more precise design, can also have higher speed ratings compared to elastomeric couplings.

Consulting Manufacturer Specifications:

To determine the torque and speed ratings for specific sizes of flexible couplings, it is essential to consult the manufacturer’s product specifications or technical datasheets. These documents provide detailed information about the coupling’s capabilities, including torque and speed ratings for each available size and model.

Application Considerations:

When selecting a flexible coupling, it is crucial to consider the torque and speed requirements of the specific application. Factors such as the power transmitted, the rotational speed of the machinery, and any transient or shock loads should be taken into account to ensure the selected coupling can handle the demands of the system.

Summary:

The torque and speed ratings of flexible couplings can vary based on their size, design, and material. Manufacturers provide specific torque and speed ratings for each coupling model to ensure their suitability for different applications. Consulting manufacturer specifications and considering the application’s requirements are vital in selecting the right flexible coupling that can handle the torque and speed demands of the mechanical system.

What are the differences between single and double flexible coupling designs?

Single and double flexible couplings are two common designs used for power transmission in various mechanical systems. Here are the main differences between the two:

- Design: The primary difference lies in their configuration. A single flexible coupling consists of one flexible element connecting two shafts, while a double flexible coupling, also known as a two-piece flexible coupling, uses two flexible elements with an intermediate shaft in between. The double flexible coupling resembles two single couplings connected in series.

- Torsional Flexibility: Single flexible couplings typically provide greater torsional flexibility than double flexible couplings. The presence of an intermediate shaft in the double coupling design adds some rigidity and reduces the overall torsional flexibility of the system.

- Compensation of Misalignment: Both single and double flexible couplings can compensate for angular and parallel misalignment between shafts. However, due to its additional flexible element, the double flexible coupling may have slightly better misalignment compensation capabilities.

- Length and Space: Single flexible couplings are generally shorter in length compared to double flexible couplings. The double flexible coupling’s design requires additional space to accommodate the intermediate shaft, making it longer than the single coupling.

- Shaft Separation: Single flexible couplings connect the two shafts directly without any intermediate components, while the double flexible coupling separates the shafts using an intermediate shaft. This shaft separation in the double design can be advantageous in certain applications.

- Stiffness: The double flexible coupling tends to be slightly stiffer than the single flexible coupling due to the presence of the intermediate shaft, which may affect its ability to absorb vibrations and shock loads.

- Application: Single flexible couplings are commonly used in various applications, including pumps, compressors, fans, and general power transmission systems. Double flexible couplings are often preferred in applications where a higher level of torsional stiffness is required, such as certain industrial machinery.

Both single and double flexible coupling designs have their advantages and are suitable for different types of machinery and power transmission requirements. The choice between the two depends on factors such as the specific application, the level of misalignment compensation needed, the available space, and the desired torsional flexibility for the system.

Can flexible couplings be used for both motor-to-shaft and shaft-to-shaft connections?

Yes, flexible couplings can be used for both motor-to-shaft and shaft-to-shaft connections in various applications. The versatility of flexible couplings allows them to adapt to different types of connections and meet the specific requirements of the system.

Motor-to-Shaft Connections:

When connecting a motor to a shaft, a flexible coupling serves as an intermediary component that joins the motor shaft and the driven shaft. Flexible couplings are commonly used in motor-driven systems to accommodate misalignment between the motor and the driven load. In motor applications, flexible couplings help reduce stress and wear on the motor bearings, thus extending the motor’s life and enhancing overall system reliability. They also act as vibration dampeners, minimizing vibrations transmitted from the motor to the driven shaft, and subsequently to connected equipment, ensuring smoother operation.

Shaft-to-Shaft Connections:

In many mechanical systems, such as those in the manufacturing, automation, and power transmission industries, shaft-to-shaft connections are required. A flexible coupling can bridge the gap between two shafts and transmit torque while accommodating misalignment. This type of coupling is commonly used to connect shafts that are not perfectly aligned due to factors like manufacturing tolerances, thermal expansion, or foundation settling. By allowing for misalignment, the flexible coupling protects the connected components from excessive stresses and ensures efficient power transmission.

Versatility and Advantages:

The ability of flexible couplings to handle both motor-to-shaft and shaft-to-shaft connections makes them versatile solutions for a wide range of industrial applications. Some of the advantages of using flexible couplings in these connections include:

- Minimizing stress and wear on connected components, such as bearings and seals.

- Compensating for misalignment, ensuring smooth power transmission.

- Damping vibrations and shock loads, reducing the risk of mechanical failures.

- Protecting equipment from excessive forces, enhancing system reliability.

- Simplifying installation and alignment procedures, reducing downtime.

- Improving overall system performance and operational efficiency.

Applications:

Flexible couplings find applications in a wide range of industries, including manufacturing, material handling, automotive, aerospace, robotics, and more. Whether connecting a motor to a shaft or joining two shafts directly, flexible couplings play a crucial role in enhancing the reliability and efficiency of rotating machinery and mechanical systems.

In conclusion, flexible couplings can effectively serve as connectors for both motor-to-shaft and shaft-to-shaft connections, providing essential misalignment compensation and protection for connected equipment in various industrial applications.

editor by CX 2024-04-22

China high quality Stainless Steel Coupling Gear Rigid Roller Chain Fluid Tyre Grid Jaw Spider HRC Nm Motor Flange Gear Pump Rubber Spline Shaft Flexible Universal Joint Coupling

Product Description

Stainless Steel Coupling Gear Rigid Roller Chain Fluid Tyre Grid Jaw Spider HRC Nm Motor Flange Gear Pump Rubber Spline Shaft Flexible Universal Joint Coupling

Product Description

Main products

Coupling refers to a device that connects 2 shafts or shafts and rotating parts, rotates together during the transmission of motion and power, and does not disengage under normal conditions. Sometimes it is also used as a safety device to prevent the connected parts from bearing excessive load, which plays the role of overload protection.

Couplings can be divided into rigid couplings and flexible couplings.

Rigid couplings do not have buffering property and the ability to compensate the relative displacement of 2 axes. It is required that the 2 axes be strictly aligned. However, such couplings are simple in structure, low in manufacturing cost, convenient in assembly and disassembly, and maintenance, which can ensure that the 2 axes are relatively neutral, have large transmission torque, and are widely used. Commonly used are flange coupling, sleeve coupling and jacket coupling.

Flexible coupling can also be divided into flexible coupling without elastic element and flexible coupling with elastic element. The former type only has the ability to compensate the relative displacement of 2 axes, but cannot cushion and reduce vibration. Common types include slider coupling, gear coupling, universal coupling and chain coupling; The latter type contains elastic elements. In addition to the ability to compensate the relative displacement of 2 axes, it also has the functions of buffering and vibration reduction. However, due to the strength of elastic elements, the transmitted torque is generally inferior to that of flexible couplings without elastic elements. Common types include elastic sleeve pin couplings, elastic pin couplings, quincunx couplings, tire type couplings, serpentine spring couplings, spring couplings, etc

Coupling performance

1) Mobility. The movability of the coupling refers to the ability to compensate the relative displacement of 2 rotating components. Factors such as manufacturing and installation errors between connected components, temperature changes during operation and deformation under load all put CHINAMFG requirements for mobility. The movable performance compensates or alleviates the additional load between shafts, bearings, couplings and other components caused by the relative displacement between rotating components.

(2) Buffering. For the occasions where the load is often started or the working load changes, the coupling shall be equipped with elastic elements that play the role of cushioning and vibration reduction to protect the prime mover and the working machine from little or no damage.

(3) Safe, reliable, with sufficient strength and service life.

(4) Simple structure, easy to assemble, disassemble and maintain.

How to select the appropriate coupling type

The following items should be considered when selecting the coupling type.

1. The size and nature of the required transmission torque, the requirements for buffering and damping functions, and whether resonance may occur.

2. The relative displacement of the axes of the 2 shafts is caused by manufacturing and assembly errors, shaft load and thermal expansion deformation, and relative movement between components.

3. Permissible overall dimensions and installation methods, and necessary operating space for assembly, adjustment and maintenance. For large couplings, they should be able to be disassembled without axial movement of the shaft.

In addition, the working environment, service life, lubrication, sealing, economy and other conditions should also be considered, and a suitable coupling type should be selected by referring to the characteristics of various couplings.

If you cannot determine the type, you can contact our professional engineer

Related products

Company Profile

Our Equipments

Main production equipment:

Large lathe, surface grinder, milling machine, gear shaper, spline milling machine, horizontal broaching machine, gear hobbing machine, shaper, slotting machine, bench drilling machine, radial drilling machine, boring machine, band sawing machine, horizontal lathe, end milling machine, crankshaft grinder, CNC milling machine, casting equipment, etc.

Inspection equipment:

Dynamic balance tester, high-speed intelligent carbon and sulfur analyzer, Blochon optical hardness tester, Leeb hardness tester, magnetic yoke flaw detector, special detection, modular fixture (self-made), etc.

Machining equipments

Heat equipment

Our Factory

Application – Photos from our partner customers

Company Profile

Our leading products are mechanical transmission basic parts – couplings, mainly including universal couplings, drum gear couplings, elastic couplings and other 3 categories of more than 30 series of varieties. It is widely used in metallurgical steel rolling, wind power, hydropower, mining, engineering machinery, petrochemical, lifting, paper making, rubber, rail transit, shipbuilding and marine engineering and other industries.

Our factory takes the basic parts of national standards as the benchmark, has more than 40 years of coupling production experience, takes “scientific management, pioneering and innovation, ensuring quality and customer satisfaction” as the quality policy, and aims to continuously provide users with satisfactory products and services. The production is guided by reasonable process, and the ISO9001:2015 quality management system standard is strictly implemented. We adhere to the principle of continuous improvement and innovation of coupling products. In recent years, it has successfully developed 10 national patent products such as SWF cross shaft universal coupling, among which the double cross shaft universal joint has won the national invention patent, SWF cross shaft universal coupling has won the new product award of China’s general mechanical parts coupling industry and the ZHangZhoug Province new product science and technology project.

Our factory has strong technical force, excellent process equipment, complete professional production equipment, perfect detection means, excellent after-sales service, various products and complete specifications. At the same time, we can provide the design and manufacturing of special non-standard products according to the needs of users. Our products sell well at home and abroad, and are trusted by the majority of users. We sincerely welcome friends from all walks of life at home and abroad to visit and negotiate for common development.p

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can flexible couplings be used in servo motor and stepper motor applications?

Yes, flexible couplings are commonly used in both servo motor and stepper motor applications. They play a crucial role in connecting the motor shaft to the driven load while compensating for misalignments and providing other essential benefits:

- Servo Motor Applications: Servo motors require precise motion control and high responsiveness. Flexible couplings are well-suited for servo motor applications because they offer the following advantages:

- Misalignment Compensation: Servo motors are sensitive to misalignments, which can lead to decreased performance and increased wear. Flexible couplings can accommodate angular, parallel, and axial misalignments, ensuring that the motor and driven load remain properly aligned during operation.

- Vibration Damping: Flexible couplings help reduce vibrations, which is crucial for servo motor applications that require smooth and precise motion. By absorbing and dissipating vibrations, flexible couplings contribute to the overall stability and accuracy of the system.

- Backlash Minimization: Some flexible couplings have minimal to no backlash, making them suitable for high-precision servo motor applications where any play or clearance between components could affect performance.

- High Torque Capacity: Servo motors often require high torque transmission capabilities. Flexible couplings are available in various designs and materials, allowing for the selection of couplings with appropriate torque ratings for specific servo motor applications.

- Stepper Motor Applications: Stepper motors are commonly used in open-loop control systems where precise positioning is necessary. Flexible couplings are used in stepper motor applications due to the following reasons:

- Misalignment Tolerance: Stepper motors can experience misalignments, especially in dynamic applications. Flexible couplings can handle misalignments without introducing significant backlash or affecting the stepper motor’s accuracy.

- Cost-Effectiveness: Flexible couplings are often more cost-effective than other types of couplings, making them a practical choice for stepper motor applications, especially in cases where precision requirements are not as stringent as in servo motor systems.

- Shock Load Absorption: Some stepper motor applications involve abrupt starts and stops, leading to shock loads. Flexible couplings can absorb these shocks and protect the motor and driven load from damage.

- Simplicity: Flexible couplings are simple in design and easy to install, making them a popular choice in various stepper motor applications.

Overall, flexible couplings offer valuable benefits in both servo motor and stepper motor applications. They help improve system performance, reduce wear on components, and enhance the overall reliability of the motion control systems they are employed in.

What are the key considerations for selecting a flexible coupling for high-speed applications?

When selecting a flexible coupling for high-speed applications, several critical considerations should be taken into account to ensure optimal performance and reliability:

- Material and Design: Choose a flexible coupling made from high-quality materials that can withstand the high rotational speeds without experiencing excessive wear or fatigue. Consider designs that are specifically engineered for high-speed applications, ensuring they have the required torsional stiffness and damping characteristics.

- Balance: Imbalance at high speeds can lead to vibration and reduce the lifespan of the coupling and connected components. Look for precision-balanced flexible couplings that minimize vibration and avoid any potential resonance issues at operating speeds.

- Torsional Stiffness: In high-speed applications, torsional stiffness is crucial to maintaining accurate rotational timing and preventing torque losses. Choose a flexible coupling with adequate torsional stiffness to minimize angular deflection under load.

- Dynamic Balancing: Dynamic balancing is essential for flexible couplings used in high-speed applications. A dynamically balanced coupling reduces vibrations caused by rotational imbalances, increasing the smoothness and stability of the system.

- Temperature Resistance: High-speed operations can generate significant heat, so select a flexible coupling that can withstand the elevated temperatures without compromising its mechanical properties or causing premature failure.

- Alignment and Runout Tolerance: Accurate alignment of the coupling with the shafts is crucial to prevent additional stress and vibration. Consider couplings with high runout tolerance and ease of alignment to facilitate proper installation.

- Service Life and Maintenance: Evaluate the expected service life of the flexible coupling in high-speed applications. Low-maintenance couplings are desirable to reduce downtime and maintenance costs.

- Application Specifics: Consider the specific requirements of the high-speed application, such as the magnitude of torque, axial movement, and the presence of shock loads. Choose a coupling that can handle these specific demands while maintaining performance at high speeds.

- Compliance with Standards: Ensure that the selected flexible coupling complies with relevant industry standards and specifications, especially those related to high-speed performance and safety.

By carefully considering these key factors, engineers can choose a flexible coupling that meets the demands of high-speed applications, delivering reliable and efficient power transmission while minimizing the risk of premature wear, vibration, and downtime.

Can flexible couplings be used in both horizontal and vertical shaft arrangements?

Yes, flexible couplings can be used in both horizontal and vertical shaft arrangements. The design of flexible couplings allows them to accommodate misalignment and compensate for angular, parallel, and axial displacements between the shafts, making them suitable for various shaft orientations.

Horizontal Shaft Arrangements:

In horizontal shaft arrangements, where the shafts are parallel to the ground or horizontal plane, flexible couplings are commonly used to connect two rotating shafts. These couplings help transmit torque from one shaft to another while accommodating any misalignment that may occur during operation. Horizontal shaft arrangements are common in applications such as pumps, compressors, conveyors, and industrial machinery.

Vertical Shaft Arrangements:

In vertical shaft arrangements, where the shafts are perpendicular to the ground or vertical plane, flexible couplings are also applicable. Vertical shafts often require couplings that can handle the additional weight and forces resulting from gravity. Flexible couplings designed for vertical applications can support the weight of the rotating equipment while allowing for some axial movement to accommodate thermal expansion or other displacements. Vertical shaft arrangements are commonly found in applications such as pumps, gearboxes, turbines, and some marine propulsion systems.

Considerations for Vertical Shaft Arrangements:

When using flexible couplings in vertical shaft arrangements, there are a few additional considerations to keep in mind:

- Thrust Load: Vertical shafts can generate thrust loads, especially in upward or downward direction. The flexible coupling should be selected based on its capacity to handle both radial and axial loads to accommodate these forces.

- Lubrication: Some vertical couplings may require additional lubrication to ensure smooth operation and reduce wear, particularly if they are exposed to high axial loads or extended vertical shafts.

- Support and Bearing: Proper support and bearing arrangements for the vertical shaft are essential to prevent excessive shaft deflection and ensure the flexible coupling functions correctly.

Overall, flexible couplings are versatile and adaptable to various shaft orientations, providing efficient power transmission and misalignment compensation. Whether in horizontal or vertical arrangements, using the appropriate flexible coupling design and considering the specific application requirements will help ensure reliable and efficient operation.

editor by CX 2024-04-16

China high quality Stainless Steel Coupling Gear Rigid Roller Chain Fluid Tyre Grid Jaw Spider HRC Nm Motor Flange Gear Pump Rubber Spline Shaft Flexible Universal Joint Coupling

Product Description

Stainless Steel Coupling Gear Rigid Roller Chain Fluid Tyre Grid Jaw Spider HRC Nm Motor Flange Gear Pump Rubber Spline Shaft Flexible Universal Joint Coupling

Product Description

Main products

Coupling refers to a device that connects 2 shafts or shafts and rotating parts, rotates together during the transmission of motion and power, and does not disengage under normal conditions. Sometimes it is also used as a safety device to prevent the connected parts from bearing excessive load, which plays the role of overload protection.

Couplings can be divided into rigid couplings and flexible couplings.

Rigid couplings do not have buffering property and the ability to compensate the relative displacement of 2 axes. It is required that the 2 axes be strictly aligned. However, such couplings are simple in structure, low in manufacturing cost, convenient in assembly and disassembly, and maintenance, which can ensure that the 2 axes are relatively neutral, have large transmission torque, and are widely used. Commonly used are flange coupling, sleeve coupling and jacket coupling.

Flexible coupling can also be divided into flexible coupling without elastic element and flexible coupling with elastic element. The former type only has the ability to compensate the relative displacement of 2 axes, but cannot cushion and reduce vibration. Common types include slider coupling, gear coupling, universal coupling and chain coupling; The latter type contains elastic elements. In addition to the ability to compensate the relative displacement of 2 axes, it also has the functions of buffering and vibration reduction. However, due to the strength of elastic elements, the transmitted torque is generally inferior to that of flexible couplings without elastic elements. Common types include elastic sleeve pin couplings, elastic pin couplings, quincunx couplings, tire type couplings, serpentine spring couplings, spring couplings, etc

Coupling performance

1) Mobility. The movability of the coupling refers to the ability to compensate the relative displacement of 2 rotating components. Factors such as manufacturing and installation errors between connected components, temperature changes during operation and deformation under load all put CHINAMFG requirements for mobility. The movable performance compensates or alleviates the additional load between shafts, bearings, couplings and other components caused by the relative displacement between rotating components.

(2) Buffering. For the occasions where the load is often started or the working load changes, the coupling shall be equipped with elastic elements that play the role of cushioning and vibration reduction to protect the prime mover and the working machine from little or no damage.

(3) Safe, reliable, with sufficient strength and service life.

(4) Simple structure, easy to assemble, disassemble and maintain.

How to select the appropriate coupling type

The following items should be considered when selecting the coupling type.

1. The size and nature of the required transmission torque, the requirements for buffering and damping functions, and whether resonance may occur.

2. The relative displacement of the axes of the 2 shafts is caused by manufacturing and assembly errors, shaft load and thermal expansion deformation, and relative movement between components.

3. Permissible overall dimensions and installation methods, and necessary operating space for assembly, adjustment and maintenance. For large couplings, they should be able to be disassembled without axial movement of the shaft.

In addition, the working environment, service life, lubrication, sealing, economy and other conditions should also be considered, and a suitable coupling type should be selected by referring to the characteristics of various couplings.

If you cannot determine the type, you can contact our professional engineer

Related products

Company Profile

Our Equipments

Main production equipment:

Large lathe, surface grinder, milling machine, gear shaper, spline milling machine, horizontal broaching machine, gear hobbing machine, shaper, slotting machine, bench drilling machine, radial drilling machine, boring machine, band sawing machine, horizontal lathe, end milling machine, crankshaft grinder, CNC milling machine, casting equipment, etc.

Inspection equipment:

Dynamic balance tester, high-speed intelligent carbon and sulfur analyzer, Blochon optical hardness tester, Leeb hardness tester, magnetic yoke flaw detector, special detection, modular fixture (self-made), etc.

Machining equipments

Heat equipment

Our Factory

Application – Photos from our partner customers

Company Profile

Our leading products are mechanical transmission basic parts – couplings, mainly including universal couplings, drum gear couplings, elastic couplings and other 3 categories of more than 30 series of varieties. It is widely used in metallurgical steel rolling, wind power, hydropower, mining, engineering machinery, petrochemical, lifting, paper making, rubber, rail transit, shipbuilding and marine engineering and other industries.

Our factory takes the basic parts of national standards as the benchmark, has more than 40 years of coupling production experience, takes “scientific management, pioneering and innovation, ensuring quality and customer satisfaction” as the quality policy, and aims to continuously provide users with satisfactory products and services. The production is guided by reasonable process, and the ISO9001:2015 quality management system standard is strictly implemented. We adhere to the principle of continuous improvement and innovation of coupling products. In recent years, it has successfully developed 10 national patent products such as SWF cross shaft universal coupling, among which the double cross shaft universal joint has won the national invention patent, SWF cross shaft universal coupling has won the new product award of China’s general mechanical parts coupling industry and the ZHangZhoug Province new product science and technology project.

Our factory has strong technical force, excellent process equipment, complete professional production equipment, perfect detection means, excellent after-sales service, various products and complete specifications. At the same time, we can provide the design and manufacturing of special non-standard products according to the needs of users. Our products sell well at home and abroad, and are trusted by the majority of users. We sincerely welcome friends from all walks of life at home and abroad to visit and negotiate for common development.p

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can flexible couplings be used in applications with high shock and impact loads?

Yes, flexible couplings can be used in applications with high shock and impact loads. In fact, they are specifically designed to absorb and dampen shock loads, making them well-suited for such challenging environments. Here’s how flexible couplings handle high shock and impact loads:

- Material Flexibility: Flexible couplings are made from materials with high elasticity and flexibility, such as elastomers (rubber-like materials) or metal alloys. When a shock load is applied, these materials can deform temporarily, absorbing the impact energy and preventing it from transmitting to the connected equipment.

- Vibration Damping: Shock loads often generate vibrations that can be harmful to the equipment. Flexible couplings with vibration-damping properties can further mitigate the effects of shock loads by absorbing and dissipating the vibration energy, reducing the stress on the machinery.

- Design Features: Some flexible couplings are specifically engineered with features to handle high shock loads. These may include reinforced structures, enhanced damping characteristics, or additional support to withstand the sudden forces generated by impacts.

- Load Distribution: Flexible couplings help distribute the shock load more evenly across the flexible elements or components, preventing localized stress concentrations that could lead to component failure.

- Resilience: The flexibility and resilience of the coupling material allow it to return to its original shape after the shock load has dissipated. This ability to recover from deformation ensures that the coupling can continue to accommodate misalignment and transmit torque effectively.

- Protection of Connected Equipment: By absorbing shock loads, flexible couplings protect the connected equipment from sudden and severe impacts, reducing the risk of damage or premature failure of critical components.

Applications with high shock and impact loads can be found in various industries, including mining, construction, material handling, and heavy machinery. Flexible couplings provide an essential role in maintaining the reliability and longevity of the equipment in these demanding environments.

When selecting a flexible coupling for an application with high shock and impact loads, it is crucial to consider the specific requirements and operating conditions. Consulting with the coupling manufacturer or a qualified engineer can ensure the proper coupling is chosen to meet the unique challenges of the application.

What are the differences between single and double flexible coupling designs?

Single and double flexible couplings are two common designs used for power transmission in various mechanical systems. Here are the main differences between the two:

- Design: The primary difference lies in their configuration. A single flexible coupling consists of one flexible element connecting two shafts, while a double flexible coupling, also known as a two-piece flexible coupling, uses two flexible elements with an intermediate shaft in between. The double flexible coupling resembles two single couplings connected in series.

- Torsional Flexibility: Single flexible couplings typically provide greater torsional flexibility than double flexible couplings. The presence of an intermediate shaft in the double coupling design adds some rigidity and reduces the overall torsional flexibility of the system.

- Compensation of Misalignment: Both single and double flexible couplings can compensate for angular and parallel misalignment between shafts. However, due to its additional flexible element, the double flexible coupling may have slightly better misalignment compensation capabilities.

- Length and Space: Single flexible couplings are generally shorter in length compared to double flexible couplings. The double flexible coupling’s design requires additional space to accommodate the intermediate shaft, making it longer than the single coupling.

- Shaft Separation: Single flexible couplings connect the two shafts directly without any intermediate components, while the double flexible coupling separates the shafts using an intermediate shaft. This shaft separation in the double design can be advantageous in certain applications.

- Stiffness: The double flexible coupling tends to be slightly stiffer than the single flexible coupling due to the presence of the intermediate shaft, which may affect its ability to absorb vibrations and shock loads.

- Application: Single flexible couplings are commonly used in various applications, including pumps, compressors, fans, and general power transmission systems. Double flexible couplings are often preferred in applications where a higher level of torsional stiffness is required, such as certain industrial machinery.

Both single and double flexible coupling designs have their advantages and are suitable for different types of machinery and power transmission requirements. The choice between the two depends on factors such as the specific application, the level of misalignment compensation needed, the available space, and the desired torsional flexibility for the system.

What industries commonly use flexible couplings for power transmission?

Flexible couplings are widely used in various industries for power transmission and motion control applications. Their ability to accommodate misalignment, dampen vibrations, and protect equipment from shock loads makes them valuable components in many industrial processes. Here are some of the industries that commonly utilize flexible couplings:

- Manufacturing: Flexible couplings are extensively used in manufacturing industries such as automotive, aerospace, electronics, and consumer goods production. They play a critical role in transmitting power between motors and various machinery, including conveyor systems, robots, and assembly lines.

- Oil and Gas: In the oil and gas industry, flexible couplings are used in pumps, compressors, turbines, and generators. They help transfer power in offshore platforms, refineries, pipelines, and drilling operations while compensating for the dynamic nature of these applications.

- Power Generation: Power plants, both conventional and renewable, rely on flexible couplings to transmit power from turbines and generators to electrical generators. They are used in coal-fired, natural gas, nuclear, hydroelectric, and wind power plants.

- Mining: In mining operations, flexible couplings are employed in various equipment, including conveyor systems, crushers, and large industrial pumps. They are designed to withstand the heavy loads and harsh conditions commonly found in mining environments.

- Marine: Flexible couplings are essential in marine propulsion systems, connecting engines to propellers or water jets. They also find use in shipboard machinery, auxiliary systems, and offshore applications.

- Pulp and Paper: The pulp and paper industry relies on flexible couplings in machinery used for wood processing, pulp production, papermaking, and printing processes.

- Chemical and Petrochemical: In chemical plants and petrochemical refineries, flexible couplings are utilized in pumps, mixers, agitators, and other rotating equipment to ensure efficient power transmission and protect sensitive machinery.

- Construction: The construction industry employs flexible couplings in various equipment, such as concrete pumps, cranes, excavators, and drilling machines.

- Water and Wastewater: Flexible couplings are used in water treatment plants, wastewater facilities, and irrigation systems to transfer power between motors and pumps.

- Agriculture: In agricultural machinery, flexible couplings are utilized in tractors, harvesters, and irrigation systems, enabling efficient power transmission and operation.

The versatility and adaptability of flexible couplings make them indispensable components in a wide range of industries, contributing to increased equipment reliability, reduced downtime, and improved overall system performance.

editor by CX 2024-03-06

China wholesaler Planetary Gear Reducer for Wheeled Vehicle Planetary Gearbox with high quality

NB602L2-25 NB602L2 NB606L2

Superior Performance

The replacement of the NBPG NB600L Serieswheel drive planetary gearbox is designed for self-propelled vehicles with hydraulic or electric motors. Available in a wide range of ratios, the gearbox allows the power system to operate at optimum efficiency. The NB600L planetary gear reducer for the wheeled vehicles has the capacity to drive whatever the type of machine with up to 2.5m of tire diameter and 50 tons each wheel. Thanks to the wide ratio range, there is a solution for any type of transmission and application. The manual declutch system can disengage the gearhead from the motor for emergency towing.

Key Features

1. Output torque range: 1000-60000 N.m

2. Gear ratios: i=5.3-142

3. Support: the gearbox has rotating housing flanges to fit the wheel

4. Applicable motors: axial piston hydraulic motors, hydraulic orbit motors or others

5. Hydraulic motor options: pressure relief valve, over-center valve

6. Bearing: robust bearing system absorbing the forces exerted by the ring gear

7. Brake: hydraulically released parking brake

8. Others: NB600L Series wheel drives with manual disconnect application

9. Large radial and axial load capacity due to the use of strongly tapered roller bearings.

10. Reliable oil seal protection, designed according to our field experience.

11. Universal and SAE input direct mounting flanges

12. The units are designed for their direct mounting into the wheel rims.

13. Technical data and installation dimension of NB600L Series gearbox are the same as those of Rexroth GFT…W Series and Bonfiglioli 600 Series, so these 3 can be used interchangeably.

edited by CX

| Track drives Type | Max. torque N.m | Range of ratios (i) | Max. Input speed (rpm) | Braking torque (N.m) |

| NB601 L1A | 1750 | 5.77 | 1000 | 450-600 |

| NB603 L2A | 4000 | 19-23-32-40 | 3000 | 210 |

| NB603 L2B | 4000 | 19-23-32-40 | 3000 | 210 |

| NB602 L2 | 5000 | 12.4-25.8 | 3000 | – |

| NB605 L2 | 7000 | 22-27-30-42-53 | 3000 | 220-310 |

| NB606 L2, L3 | 12000 | 30-35-43-68-79 | 3000 | 300-800 |

| NB607 L2, L3 | 17000 | 33-75-108 | 3000 | 300-600 |

| NB609 L2, L3 | 23000 | 33-142 | 3000 | 300-600 |

| NB610 L2, L3 | 30000 | 20-111 | 3000 | 300-800 |

| NB611 L2, L3 | 36000 | 41-47 | 3000 | 300-800 |

| NB613 L3 | 45000 | 108 | 3000 | 300-800 |

| NB615 L3 | 60000 | 108 | 3000 | 300-1000 |

Our planetary gearbox, wheel drive gearbox, winch drive gearbox, and track drive gearbox can be alternatives to Bosch Rexroth gearboxes

| GFT13W2 | GFT17W2 | GFT17W3 | GFT24W2 | GFT26W2 | GFT36W3 | GFT40W2 |

| GFT50W3 | GFT60W3 | GFT80W3 | GFT110W3 | GFT160W3 | GFT220W3 | GFT330W3 |

The NB600L gearbox can be alternative to Trasmital Bonfiglioli

| 601R | 603W | 605W | 606W | 609W | 611W | 613W 615W |

China manufacturer & factory supplier for R in Davanagere India series helicalgear motoreductor helical bevel gear motor cyclo gearbox redutor cradle reducer transmission gearbox With high quality best price & service

EPG roller chain satisfies or exceeds ANSI expectations and is made in ISO qualified factories. As is the situation with our pillow block bearings and ball bearings, our roller chain components are tested prior to cargo to insure quality. The roller chain parts and roller chains we source are pre-stretched to insure you have constrained sag. It also arrives with sound rollers, ensuring that it is of the optimum quality.We examine every piece of bearing by ourselves prior to supply.

Overview

Fast Information

- Applicable Industries:

-

Producing Plant, Equipment Repair Stores, Foods & Beverage Manufacturing unit, Farms

- Place of Origin:Zhejiang, China

- Model Identify:

-

OEM

- Gearing Arrangement:

-

Helical

- Output Torque:

-

800~100000N.m

- Enter Pace:

-

1400rpm

- Output Pace:

-

14-280rpm

- Ratio:

-

7.5~one hundred

- Certification:

-

ISO9001-2008

- Mount Placement:

-

Foot Mounted

- Bearing:

-

LYC,SKF

Provide Capability

- Provide Ability:

- 500 Device/Models for every Month

Packaging & Supply

- Packaging Specifics

- Picket boxes , Cantons packed in 1 pallet

- Port

- Ningbo Port, Shanghai Port

-

The PTO shaft provided with all Victory Tractor mowers has a more time extension than the normal PTO Shaft. The included size is necessary since of the significantly reaching motion of the mowers to the appropriate of the tractor.

-

Lead Time

: -

Quantity(Containers) Building ON Management IN INNOVATION Our investments in investigation and advancement drastically exceed the sector typical. This is a end result of our distinct tradition of innovation.

1 – one >1 Est. Time(times) 20 To be negotiated

On-line Customization

Item Description

R collection helicalgear motoreductor helical bevel equipment motor cyclo gearbox redutor cradle reducer transmission gearbox

SLR helical reducer has the functions of substantial flexibility,very good combination and large loading capability, together with other deserves this kind of as effortless to achieve a variety of transmission ratios, higher performance, minimal vibrationand high permissible axis radial load. This collection can not only be merged with numerous varieties of reducers and variators and meet up with the demands, but also beadvantage of localization of relevant transmission gear.

Specs:

1) Output velocity: .6~1,028r/min

2) Output torque: up to 18,000N.m

3) Motor electrical power: .eighteen~160kW

4) Mounted type: foot-mounted and flange-mounted mounting

|

Solution Title |

SLR Collection Rigid Tooth helical reducer |

|

Equipment MateriEPG is willing to cooperate sincerely and develop frequently with friends!al |

20CrMnTi |

|

Circumstance Substance |

HT250 |

|

Shaft Material |

20CrMnTi |

|

Equipment Processing |

Grinding finish by HOFLER Grinding Equipment |

|

Color |

Tailored |

|

Sounds Take a look at |

Bellow 65dB |

Merchandise Present

High quality Control

Our Firm

Packing & Supply

Packing Particulars : Packing, strong bicycle saddle, 50pcs/carton

Shipping and delivery Information : 3-thirty days after order of Strong bicycle tire tubes

FAQ

Q: Are you trading organization or maker ?

A: We are factory.

Q: How prolonged is your shipping time?

A: Normally it is 5-10 days if the products are in inventory. or it is 15-20 times if the products are not in stock, it is according to quantity.

Q: Do you provide samples ? is it totally free or additional ?

A: Yes, we could supply the sample for totally free cost but do not shell out the value of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, thirty% T/T in advance ,equilibrium just before shippment.

If you have yet another query, pls truly feel cost-free to get in touch with us as under:

Get in touch with

China manufacturer & factory supplier for S in Ipoh Malaysia series dual shaft output helical worm gear speed reducer With high quality best price & service

EP Team has increased its business lines to contain Energy Transmission Units and ComponeOur items are selling well in Chinese markets and some merchandise offered in intercontinental markets are effectively acquired by Chinese and international clientele at house and overseas.nts, Automotive Elements and Resources Dealing with Programs.EPG has been efficiently licensed by ISO9002 Top quality Administration System, ISO9001 High quality Administration Method, API certification, ISO/TS16949:2002 and ISO10012 measurement management method.

Cat 3 Point Hitch How do I run the PTO on my tractor? Prior to managing the PTO, you will need to have your tractor to get to the starting RPM (revolutions for every minute). After the beginning RPM has been attained you can begin operating the PTO.

Overview

Quick Particulars

- Relevant Industries:

-

Constructing Material Stores, Manufacturing Plant, Machinery Repair Outlets, Farms, Design works , Meals & Beverage Outlets

- Item identify:

-

Worm Equipment Reducer

- Colour:

-

Blue,Gray,Or Personalized

- Guarantee:

-

one Yr

- Application:

-

Food ,Plastic, Convery, Machinery, Feed, Mining and so on

- Certification:

-

ISO9001 , CE

- Mounting Place:

-

Horizontal (Foot Mounted, Shaft Mounted)

- Packing:

-

Wood Box

- Ratio:

-

9.96-244.74

- Bearing:

-

C&U, NAK, NSK,SKF

- OEM services:

-

Obtainable

Offer Capability

- Source Potential:

- a thousand Piece/Parts for each Thirty day period

Packaging & Shipping and delivery

- Packaging Specifics

- Plywood circumstance

- Port

- Ningbo,Shanghai

-

Direct Time

: -

Breathers or vent plugs get rid of internal force buildup, but usually give a leakage path for lubricant. Bubbles of oil sort above the air passageway and sooner or later percolate to the outside.

Amount(Bins) one – 10 >10 Est. Time(times) fifteen To be negotiated

On the web Customization

Functions

Substantial modular design and style, biomimetic floor with owned intellectual property correct.

Undertake German worm hob to procedure the worm wheel.

With the specific equipment geometry, it receives high torque, effectiveness and lengthy daily life circle.

It can accomplish the direct blend for two sets of gearbox.

Mounting manner: foot mounted, flange mounted, torque arm mounted.

Output shaft: reliable shaft, hollow shaft.

Major used for

Chemical business and environmental security

Metallic processing

Developing and building

Agriculture and meals

Textile and leather

Forest and paper

Auto washing equipment

Housing substance | Cast iron/Ductile iron |

Housing hardness | HBS190-240 |

Gear material | 20CrMnTi alloy steel |

Surface area hardness of gears | HRC58°~62 ° |

Equipment core hardness | HRC33~40 |

Input / Output shaft materials | 42CrMo alloy steel |

Input / Output shaft hardness | HRC25~30 |

Machining precision of gears | accurate grinding, 6~5 Quality |

Lubricating oil | GB L-CKC220-460, Shell Omala220-460 |

Warmth therapy | tempering, cementiting, quenching, and so on. |

Performance | ninety four%~96% (is dependent on the transmission stage) |

Noise (MAX) | sixty~68dB |

Temp. increase (MAX) | 40°C |

Temp. rise (Oil)(MAX) | 50°C |

Vibration | ≤20µm |

Backlash | ≤20Arcmin |

Brand of bearings | China top brand name bearing, HRB/LYC/ZWZ/C&U. Or other manufacturers requested, SKF, FAG, INA, NSK. |

Model of oil seal | NAK — Taiwan or other brands requested |

Q: Are you trading firm or maker ?

A: We Ever-Electricity Group 1 of the biggest transmission suppliers in the entire world are manufacturing unit.

Q: How long is your delivery time?

A: Normally it is 5-10 times if the items are in stock. or it is 15-20 days if the items are not in inventory.

Q: Can we acquire 1 personal computer of every single merchandise for high quality tests?

A: Sure, we are glad to settle for demo order for quality testing.

Q: What is your phrases of payment ?

A: Payment=1000USD, thirty% T/T in advance, harmony just before shippment.

If you have other query, freely to get in touch with us,make sure you.

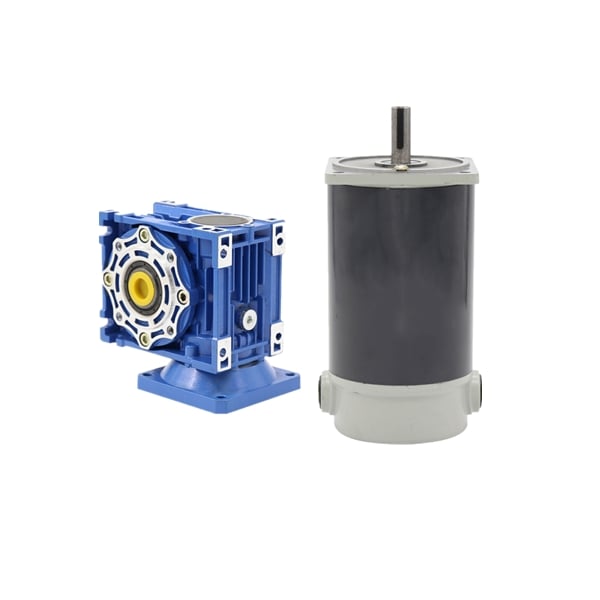

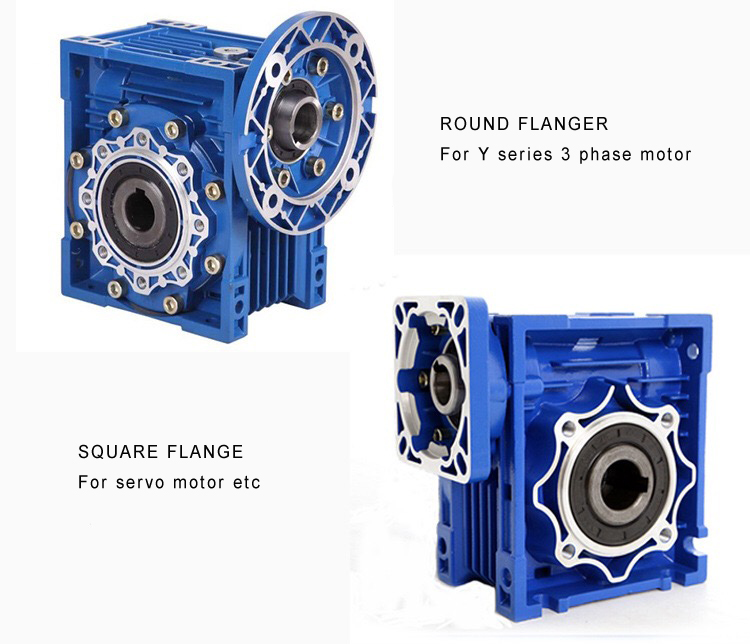

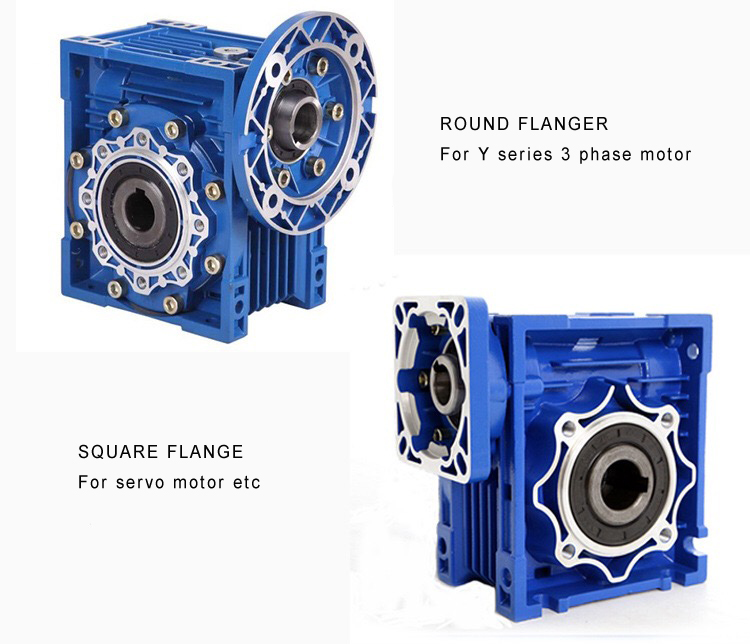

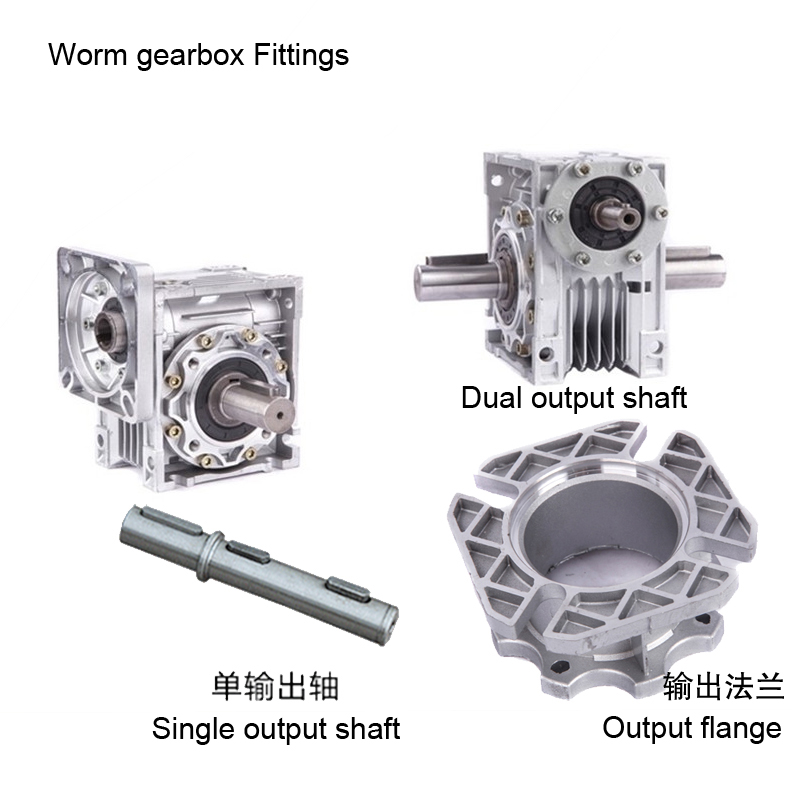

China manufacturer & factory supplier for NMRV030 in Pekan Baru Indonesia gearbox reduction ratio with DC 12V 24V 22rpm worm gear motor 1 2HP power With high quality best price & service

industrial elements like roller chains. Roller chains are offered in normal, nickel plated & stainless metal components in pitch dia. ranging from 1/4 in. to 3 in. Sorts contain leaf chains in lacing configurations ranging from 2 x 2 to 8 x 8. Leaf chains are accessible in pitch sizes ranging from 1/2 in. to 2 in., pin dia. ranging from .156 in. to .687 in. & tensile strengths ranging from 4,000 lbs. to 156,000 lbs. Applications contain agricultural, conveyors, drilling, electronics assembly, foodstuff processing, fork raise vans, hoists, packaging & textile equipment.Quality and credit history are the bases that make a corporation alive. a specialised supplier of a entire range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Fast Specifics

- Relevant Industries:

-

Manufacturing Plant

- Product NO:

-

SYF

- Color:

-

Blue

- Item identify:

-

Worm Gear Screw Jack

- Materials:

-

Aluminium Alloy

- Application:

-

Device Tool

- Bearing:

-

NSK

- Certificate:

-

ISO9001

- Ratio:

-

5-100

- Mounting Placement:

-

Flange Mounted

- Enter Sort:

-

IEC Flange

Packaging & Delivery

-

Guide Time

: -

Quantity(Luggage) one – three 4 – five >5 Est. Time(times) six ten To be negotiated

On-line Customization

Mounting Dimension

The items are broadly used in the creating equipments of all varieties of industries inside and exterior China. They are the best options for presently contemporary services of mechanical reducing push management to comprehend large twisting length, big gear ratio, small sound, higher effectiveness and balance.

|

Design: |

NMRV025, 030, 040, 050, 063, 075, 090, 110, a hundred thirty, 150 |

|

Ratio: |

1:5,7.5,10,15,twenty,25,thirty,forty,fifty,60,80,a hundred |

|

Colour: |

Blue, Silver Or On Customer Ask for |

|

Sound: |

lower noise (<50DB) |

|

Advantage: |

Successful and secure functioning |

|

Materials: |

Housing: Die-Forged Aluminum Alloy |

|

Worm Equipment-Bronze 9-4# |

|

|

Worm-20CrMnTi with carburizing and quenching, surface harness is 56-62HRC |

|

|

Shaft-chromium metal-forty five# |

|

|

Packing: |

Carton and Wooden Circumstance |

|

Bearing: |

C&U Bearing |

|

Seal: |

NAK SKF |

|

Certification: |

ISO9001,CE,3C,OEM |

|

Warranty: |

twelve months |

|

Input Power: |

.06kw, .09kw, .12kw, .18kw, .25kw, .37kw, .55kw, .75kw, 1.1kw, 1.5kw, 2.2kw, 3kw, 4kw, 5.5kw, 7.5kw, 11kw, 15kw |

|

Usages: |

Industrial Device: Foodstuff Stuff, Ceramics,CHEMICAL,Packing,Dyeing, Woodworking,Glass. |

|

IEC Flange: |

56B5, 56B14, 63B5, 63B14, 71B5, 71B14, 80B5, 80B14, 90B5, 90B14, 100B5, 100B14, 112B5, 112B14, 132B5, 160B5 |

|

Lubricant: |

Synthetic & Mineral |

Merchandise Deseription

Single Action Worm Equipment Reducer.

The reducer which product is twenty five~ninety manufactured of Aluminum alloy die-casting box,very good hunting in look,compact in framework,rust proofing on surface area and modest volume to conserve mounting area.

The reducer model of a hundred and ten~150 is created of solid iron which casted with Aluminum mould.It`s good looking and strong, and can be used by means of the setting of multi-azimuth.

Good radiating characterstic prospects risk-free and reliability,and high efficiency for utilizing.

The powerful ability of loading ensure steady transmission,make significantly less vibration and sound.

Varies of connecting framework for energy input and torque output meet up with distinct demand-meritsthe design of box define and the set of foot hole with great versality is apt to several varieties of mounting.

The NMRV worm gearbox is new generation of products by our manufacturing unit on the basis of perfecting WJ collection merchandise with compromise of advanced technological innovation the two at house and overseas.It truly is apprearance adopts innovative square box framework.It is outer human body is created of substantial top quality aluminium alloy die casting into forming.It is tiny in quantity,light-weight bodyweight,high in radiating efficiency,huge in output torque,sleek in working and reduced sounds.It really is suitbalOur business has solid economic toughness, builds up a technician staff contingent with high top quality, possesses the manufacturing assembly line of technicalization in China and ideal technique examining on merchandise high quality and runs marketing networks through the region. e for all positions.

Approach for model picked

Make sure you realize the pursuing at 1st in get to delect the modelRV025~RV150 Strong Shaft Input RV025~RV150 Characteristics: 1. High quality aluminum alloy gear box, mild fat and not rust 2. 2 optional worm wheel supplies: Tin (Stannum) bronze or aluminum bronze alloy 3. Standard areas and very versatile for shaft configurations and motor flange interface 4. Many optional mounting possibilities 5. Reduced noise, Higher effectiveness in heat dissipation of RV speed reducer effectively.

– Loading issue

– Velocity scope or ratio in application

– Doing work condition and surroundings

– Installation area

Company profile

HangZhou EPT Group – one particular of the greatest gearbox manufacturer in China – Electromechanical Facilities Co. Ltd

HangZhou EPT Team – 1 of the most significant gearbox manufacturer in China – Electromechanical Equipment Co., Ltd.is a present company integrating growth, design, creation and income,Main promoting goods consist of reducer motor,h2o pump,design machinery and areas,bearings,hardware and electrical equipment,plastic merchandise,Labour security equipment.Our firm always follow the operation principle which contains men and women-oriented, innovation as the soul,be well prepared for hazard in instances of peace, unremitting……

Software spot

Certifications

Detailed Photographs

Packing & Delivery

|

Packaging |

||

|

Measurement |

500 (L) * 500 (W) * 400 (D) |

|

|

Fat |

1.2 T |

|

|

Packaging Details |

The regular package deal is wood box(Measurement: L*W*H). If export to european nations,the wooden box will be fumigated.If container is also tigher,we will use pe film for packing or pack it in accordance to clients unique request. |

|

|

Packaging |

||

|

Dimension |

500 (L) * five hundred (W) * 400 (D) |

|

|

Weight |

1.2 T |

|

|

Packaging Information |

The regular deal is picket box(Measurement: L*W*H). If export to european international locations,the wood box will be fumigated.If container is way too tigher,we will use pe film for packing or pack it in accordance to buyers unique ask for. |

|

FAQ

Q1: Are you investing firm or company ?

A: We are a company in ZheJiang China.welcome to our manufacturing unit to have a pay a visit to.

Q2: How we pick versions and specs?

A:You can electronic mail us the series name & code (for illustration: WJ series worm gearbox) as properly as need details, this kind of as motor power, output pace or ratio, support element or your application…as significantly knowledge as achievable. If you can source some photographs or drawings, it is greater.

Q3: How is your price? Can you offer any low cost?

A: We will give the best value we can foundation on your wants and the portions.

Q4: How lengthy must I wait around for the opinions after I send out the enquiry?

A: In 12 hrs.

Q5: What is your solution guarantee period?

A:We offer you one year guarantee given that the vessel departure date remaining China.

Q6: What industries are your gearboxes becoming employed?

A:Our gearboxes are widely applied to metallurgical tools, mining products, automation gear, foods machinery, packaging products, tobacco equipment and so on.

Make contact with us

Cellular: +86-13083988828 we chat # or 0086-571-88220971 (WeChat)

E-mail:hzptcorp (a) gmail.com

Fox:+86-571-88220972

Add:No.789 ShenHua Road, , XiHu District, HangZhou, ZheJiang, China

HangZhou EPT Upkeep Upkeep on these units is straight forward and like all relocating areas these need to have their reasonable share of grease and ought to be greased routinely as these factors work quite tough and are subject matter to all that mother nature can supply for dress in and tear. Excellent grease is vital here place grease in until you see the previous grease oozing out. Go effortless on the “U” joints so you do not blow the seals. Short bursts of a low pressured air grease gun or even greater a hand pump gun will do the occupation and need to be accomplished based on hourly use. At minimum once a year the main and secondary shafts must be separated. All particles and any rust should be cleaned off. Examine totally for any symptoms of stress and apply a liberal quantity of grease. In addition to this, equally the PTO yoke holes need grease inside of of them at least once a 12 months alongside with the yoke lock pin.Group – one of the greatest gearbox manufacturer in China – Electromechanical Amenities Co. Ltd.

China made in China – replacement parts – in Nashville United States Supplier High Precision Metal Spur Gear with ce certificate top quality low price

We – EPG Team the bigge EPT Chain and agricultural gearbox manufacturing facility in China with 5 distinct branches. For much more information: Cellular/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Solution specification

one.Substance:C forty five# metal ,stainless steel or EPT necessary supplies.

two.Gears can be made in accordance the customer’s drawings

3.Warmth treatment: Hardening and Tempering, Large Frequency Quenching, Carburizing Quenching and so on according the demands..

four. Inspection: All things are checked and analyzed thoroughly in the course of every single operating process and right after generation will be reinspected.

About us

HangZhou EPT Sprocket Co., Ltd. is a professional producer of a variety of sprocket wheels, stainless steel sprocket wheels, non-normal sprocket wheels, large pitch sprocket wheels, coupling sprocket wheels, spur gears, timing belt wheels, gear racks, umbrella Gear, worm gear, shaft, sleeve and EPT transmission elements producers. And according to consumer drawings, samples, dimensions processing personalized production. The organization integrates layout R & D, manufacturing and sales. In accordance with rigorous production, inspection and good quality expectations, the business has established a complete high quality technique, generation approach and perfect quality management. The firm’s sprocket products are of substantial quality, security and toughness.

The firm now has 80 sets of various large-precision CNC lathes, equipment hobbing machines, equipment shapers, tempering furnaces, quenching gear, gantry planers, universal milling, sawing devices, vertical broaching devices, hydraulic devices and EPT processing tools, with an annual generation capability of 2 million items . Carburizing and quenching, nitriding, quenching and EPT heat therapy, surface area blackening, galvanizing, electrophoresis, and so forth. At the same time, it also has high-precision screening gear such as: Rockwell hardness tester, Vickers hardness tester, metallographic microscope, impression measuring instrument, Magnetic particle flaw detectors, etc. The products created are widely used in metallurgy, steel, chemical, textile, agricultural equipment, 3-dimensional garages, packaging equipment, chemical equipment, pharmaceutical machinery, industrial and mining equipment and EPT industries. The item indicators meet the needs of importing similar items and are exported to Hong Kong and ZheJiang , Southea EPT Asia, Europe, The usa, the Middle Ea EPT and EPT regions, and are deeply dependable and praised by clients.

FAQ

Q: Are you trading organization or maker ?

A: We are manufacturing unit.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the merchandise are in stock. or it is fifteen-twenty days if the goods are not in inventory, it is according to quantity.

Q: Do you supply samples ? is it totally free or further ?

A: Sure, we could offer the sample for totally free charge but do not pay the co EPT of freight.

Q: What is your phrases of payment ?

A: Payment 30%TT in advance. 70% T/T prior to shippment.

Q:What`s the MOQ of your items?

A:1 established,we can also offer with the sample purchase. and the huge-quantity.

The use of unique tools manufacturer’s (OEM) part figures or logos , e.g. CASE® and John Deere® are for reference functions only and for indicating product use and compatibility. Our organization and the outlined alternative areas contained herein are not sponsored, accepted, or manufactured by the OEM.

Hotsale near me made in China – replacement parts – in San Jose del Monte Philippines High Precision Transmission Gear Timing Pulley with Keyway with top quality

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears manufacturing facility in China with 5 different branches. For more particulars: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

hotsale High precision Transmission equipment timing pulley with Keyway

Merchandise Description:

Transmission Straight Tooth Spur Gear with Keyway

Pulley Styles Variety:

Main Characteristics:

Spur Gear

one. Produce strictly in accordance with ANSI or DIN normal dimension

2. Substance: SCM 415 steel

three. Bore: Completed bore

4. Precision quality: DIN 5 to DIN 7

5. Floor treatment method: Carburizing and Quenching

six. Module: From 1 to four

seven. Tooth: From Z15 to Z70

| Product name | Spur Gear |

| Materials Available | Stainless Steel, Carbon Steel, Brass, Bronze, Iron, Aluminum Alloy etc |

| BORE | Completed bore, Pilot Bore, Unique ask for |

| Processing Method | Molding, Shaving, Hobbing, Drilling, Tapping, Reaming, Guide Chamfering, Grinding etc |

| Strain Angle | 20 Diploma |

| Hardness | 55- 60HRC |

| Dimensions | Buyer Drawings & ISO standard |

| Package deal | Wooden Circumstance/Container and pallet, or manufactured-to-order |

| Certificate | ISO9001:2008 |

EPT Sorts

| Kind | Module | Materials | Surface area remedy | Precision quality | Tooth Variety |

| MSGA,MSGB | one~four | SCM415 | Carburizing and Quenching | N5 | eighteen~100 |

| SSGS | 1.5~three | S45C | Tempering, tooth floor high quenching hardening | N7 | 10~13 |

| SSG | .5~six | S45C | Tooth floor high quenching hardening | N7 | thirty~80 |

| SSS | .5~3 | S45C | Tempering | N8 | ten~thirteen |

| SS | .5~ten | S45C | – | N8 | fifteen~a hundred and twenty |

| SSA | one~five | S45C | – | N8 | twenty~one hundred |

| SSY | .8, 1 | S45C | – | N8 | twenty~one hundred twenty |

| SSAY | 1 | S45C | – | N8 | |

| BSS | .5~one | Brass C3604 | – | N8 | 15~sixty |

| SUS, SUSA | one~four | SUS303 | – | N8 | 15~120 |

Pulley Generation Workshop and Application:

| Programs | Toy, Automotive, instrument, electrical products, house appliances, home furniture, mechanical gear,day-to-day residing products, digital sporting activities tools, , sanitation machinery, market/ hotel tools supplies, and so on. |

Our Business:

HangZhou Hefa Equipment EPT Co.,L EPT proven in 2009, is a specialist manufacture engaged in growth, generation, product sales and provider of timing pulley, precise spur gears, helical gears, bevel gear, worm& worm equipment and so on. We found in HangZhou with hassle-free transposition excite. Hefa Equipment EPT focused to rigorous high quality control and thoughtful buyer services. Our seasoned staffs are usually offered to discuss your specifications, and fulfill your fulfillment.

Manufacturing procedure: Molding Chopping, Gear Hobbing, Gear Milling, Equipment Shaping, Equipment Broaching,Gear Shaving, Gear Grinding and Equipment Lapping.

Inspection:

Hefa Equipment EPT dedicated to rigid good quality manage.” Focus and Skilled on the Growth of EPT Area” this is Hefa Gear EPT focus on. Function step by phase, Hefa usually offer success solution in exact conveyor discipline. Offering be EPT cost, super support and typical supply are always our priorities.

Packaging, Inventory and Supply:

| Packaging | Polyethylene bag or oil paper for each product Pile on carton or as customer’s desire |

| Delivery of Samples | By DHL, Fedex, UPS, TNT, EMS |

| Direct time | ten-fifteen operating times as typical, 30days in hectic year, it will based on the thorough order amount. |

FAQ:

| Major Marketplaces? | North America, South The us, EPT Europe , We EPT Europe , North Europe, South Europe, Asia |

| How to purchase? | * You send out us drawing or sample |

| * We carry by way of task assessment | |

| * We give you our style for your confirmation | |

| * We make the sample and deliver it to you after you verified our design and style | |

| * You confirm the sample then location an order and pay us thirty% deposit | |

| * We start off producing | |

| * When the items is completed, you shell out us the harmony right after you confirmed pictures or tracking figures. | |

| * Trade is carried out, thank you!! |

If you are interested in our items, please notify us which supplies, sort, width, length u want.

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears factory in China with 5 various branches. For more details: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828 The use of unique tools manufacturer’s (OEM) element numbers or trademarks , e.g. CASE® and John Deere® are for reference reasons only and for indicating merchandise use and compatibility. Our organization and the shown substitute elements contained herein are not sponsored, accredited, or created by the OEM.

Best China manufacturer & factory factory in Riga Latvia manufacturer for High quality pinion ring gear wheel rack With high quality best price

EPG has been effectively licensed by ISO9002 High quality Administration System, ISO9001 Quality Management Method, API certificate, ISO/TS16949:2002 and ISO10012 measurement management program.

Overview

Quick Specifics

- Applicable Industries:

-

ManufacturSlip Clutch PTO Shaft for Compact Tractor Tillers NEW SLIPCLUTCH PTO SHAFT FOR COMPACT TRACTOR TILLERS ROTO TILLERS BUSHHOG RHINO KINGKUTTER,CARONI,MASCHIO,JOHN DEERE, MOST Designs a few distinct kinds of PTO in operation: a non shear, shear pin and slip clutch — the final becoming the most high-priced. Put into action end of non shear (r) and shear kind (l) Non shear: this is a solid yoke to yoke established up and utilised with the expectation that specific gear will not experience any sudden stops. I determine that the finishing mower does not require a shear set up as the blades will slip to a degree getting belt pushed and my other mower, the flail mower, is really forgiving in its layout.ing Plant

- Merchandise Search phrases:

-

pinion ring gear,pinion equipment wheel,pinion equipment rack

Supply Potential

- Supply Capacity:

- 5000 Piece/Parts per Month

Packaging & Delivery

- Packaging Details