Product Description

Product Description

Product Parameters

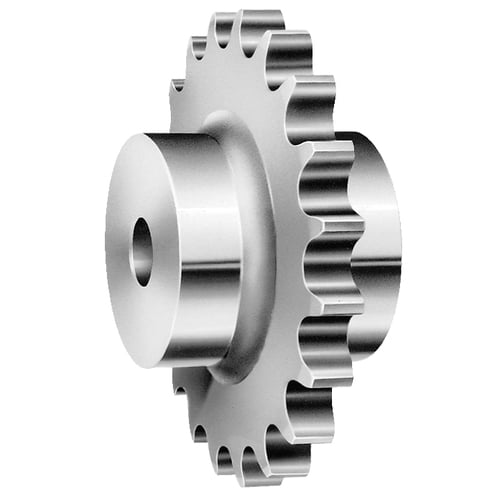

| product | Kc Series Steel Casting Flexible Sprocket Roller Chain Coupling for test benches |

| material | stainless steel , iron , aluminum ,bronze ,carbon steel ,brass etc . |

| size | ISO standard ,customer requirements |

| kind | expansion sleeve Z1/Z2/Z3/Z4/Z5/Z6/Z7/Z8/Z9/Z10/Z11/Z12/Z13/Z14/Z18/Z19 |

| BORE | Finished bore, Pilot Bore, Special request |

| surface treatment | Carburizing and Quenching,Tempering ,Tooth suface high quenching Hardening,Tempering |

| Processing Method | Molding, Shaving, Hobbing, Drilling, Tapping, Reaming, Manual Chamfering, Grinding etc |

| Heat Treatment | Quenching & Tempering, Carburizing & Quenching, High-frequency Hardening, Carbonitriding…… |

| Package | Wooden Case/Container and pallet, or made-to-order |

| Certificate | ISO9001 ,SGS |

| Machining Process | Gear Hobbing, Gear Milling, Gear Shaping, Gear Broaching, Gear Shaving, Gear Grinding and Gear Lapping |

| Applications | Toy, Automotive, instrument, electrical equipment, household appliances, furniture, mechanical equipment,daily living equipment, electronic sports equipment, , sanitation machinery, market/ hotel equipment supplies, etc. |

| Testing Equipment | Rockwell hardness tester 500RA, Double mesh instrument HD-200B & 3102,Gear measurement center instrument CNC3906T and other High precision detection equipments |

workshop & equipment

Production process

Certifications

Our Advantages

1 . Prioritized Quality

2 .Integrity-based Management

3 .Service Orientation

4 .150+ advanced equipment

5 .10000+ square meter factory area

6 .200+ outstanding employees

7 .90% employees have more than 10 year- working experience in our factory

8 .36 technical staff

9 .certificate ISO 9001 , SGS

10 . Customization support

11 .Excellent after-sales service

shipping

sample orders delivery time:

10-15 working days as usual

15-20 working days in busy season

large order leading time :

20-30 working days as usual

30-40 working days in busy season

FAQ

1. why should you buy products from us not from other suppliers?

We are a 32 year-experience manufacturer on making the gear, specializing in manufacturing varieties of gears, such as helical gear ,bevel gear ,spur gear and grinding gear, gear shaft, timing pulley, rack, , timing pulley and other transmission parts . There are 150+ advanced equipment ,200+ excellent employees ,and 36 technical staff . what’s more ,we have got ISO9001 and SGS certificate .

2 .Do you accept small order?

If your order bearings are our standard size, we accept even 1pcs.

3 .How long is the delivery?

A: Small orders usually takes 10-15 working days,big order usually 20-35 days, depending on orders quantity and whether are standard size.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

How do flexible couplings handle shaft misalignment in rotating equipment?

Flexible couplings are designed to handle shaft misalignment in rotating equipment, providing several key features that allow them to accommodate misalignment effectively. Here’s how they work:

- Angular Misalignment: Flexible couplings can handle angular misalignment, which occurs when the axes of the connected shafts are not perfectly aligned. The coupling’s flexible elements allow for slight angular deviation, ensuring that the torque can still be transmitted smoothly between the shafts.

- Parallel Misalignment: Parallel misalignment occurs when the connected shafts are not perfectly in line but run parallel to each other. Flexible couplings can compensate for this misalignment by utilizing their ability to flex or slide, allowing the shafts to remain connected while maintaining rotational integrity.

- Axial Misalignment: Axial misalignment refers to the situation where the connected shafts have a slight axial displacement. Some flexible couplings have specific designs to handle axial misalignment, allowing for limited movement along the axial direction without compromising the connection between the shafts.

- Double Flexing: Certain types of flexible couplings, such as the double-flexing couplings, can accommodate both angular and parallel misalignments simultaneously. These couplings use two sets of flexible elements to achieve this capability, providing a higher degree of misalignment compensation.

Overall, the flexibility of the coupling’s material and design allows it to bend, flex, or slide in response to the misalignment, reducing the stress on the connected equipment and ensuring smooth power transmission. By accommodating misalignment, flexible couplings help prevent premature wear, reduce vibration, and extend the service life of the rotating equipment.

How does a flexible coupling handle torsional vibrations in rotating machinery?

A flexible coupling is designed to handle torsional vibrations in rotating machinery by providing a degree of flexibility and damping. Torsional vibrations are oscillations that occur in the drivetrain due to torque variations, sudden load changes, or other transient events. These vibrations can lead to resonance, excessive stress, and premature failure of components.

Flexible couplings mitigate torsional vibrations through the following mechanisms:

- Torsional Compliance: Flexible couplings have an element, such as an elastomeric insert, that can deform or twist to absorb torsional shocks. When the drivetrain experiences torsional vibrations, the flexible element flexes, effectively isolating and dampening the vibrations before they propagate further.

- Damping: Many flexible couplings have inherent damping properties, especially those with elastomeric components. Damping dissipates the energy of the torsional vibrations, reducing their amplitude and preventing resonance from occurring.

- Tuned Design: Some flexible couplings are specifically designed with specific torsional characteristics to match the drivetrain’s requirements. By tuning the coupling’s stiffness and damping properties, engineers can ensure optimal torsional vibration control.

- Torsional Stiffness: While flexible couplings provide flexibility to absorb vibrations, they also offer a degree of torsional stiffness to maintain the torque transmission efficiency between the shafts.

It is important to select the appropriate flexible coupling based on the specific torsional characteristics and requirements of the rotating machinery. Different applications may demand different types of couplings with varying levels of flexibility and damping. High-performance flexible couplings can effectively minimize torsional vibrations, protecting the drivetrain and connected equipment from excessive stress and potential damage.

Additionally, proper alignment of the flexible coupling during installation is crucial to ensure its optimal performance in mitigating torsional vibrations. Misalignment can introduce additional stresses and exacerbate torsional issues in the system. Regular inspection and maintenance of the flexible coupling will help identify any signs of wear or damage that may affect its ability to handle torsional vibrations effectively.

Can flexible couplings be used for both motor-to-shaft and shaft-to-shaft connections?

Yes, flexible couplings can be used for both motor-to-shaft and shaft-to-shaft connections in various applications. The versatility of flexible couplings allows them to adapt to different types of connections and meet the specific requirements of the system.

Motor-to-Shaft Connections:

When connecting a motor to a shaft, a flexible coupling serves as an intermediary component that joins the motor shaft and the driven shaft. Flexible couplings are commonly used in motor-driven systems to accommodate misalignment between the motor and the driven load. In motor applications, flexible couplings help reduce stress and wear on the motor bearings, thus extending the motor’s life and enhancing overall system reliability. They also act as vibration dampeners, minimizing vibrations transmitted from the motor to the driven shaft, and subsequently to connected equipment, ensuring smoother operation.

Shaft-to-Shaft Connections:

In many mechanical systems, such as those in the manufacturing, automation, and power transmission industries, shaft-to-shaft connections are required. A flexible coupling can bridge the gap between two shafts and transmit torque while accommodating misalignment. This type of coupling is commonly used to connect shafts that are not perfectly aligned due to factors like manufacturing tolerances, thermal expansion, or foundation settling. By allowing for misalignment, the flexible coupling protects the connected components from excessive stresses and ensures efficient power transmission.

Versatility and Advantages:

The ability of flexible couplings to handle both motor-to-shaft and shaft-to-shaft connections makes them versatile solutions for a wide range of industrial applications. Some of the advantages of using flexible couplings in these connections include:

- Minimizing stress and wear on connected components, such as bearings and seals.

- Compensating for misalignment, ensuring smooth power transmission.

- Damping vibrations and shock loads, reducing the risk of mechanical failures.

- Protecting equipment from excessive forces, enhancing system reliability.

- Simplifying installation and alignment procedures, reducing downtime.

- Improving overall system performance and operational efficiency.

Applications:

Flexible couplings find applications in a wide range of industries, including manufacturing, material handling, automotive, aerospace, robotics, and more. Whether connecting a motor to a shaft or joining two shafts directly, flexible couplings play a crucial role in enhancing the reliability and efficiency of rotating machinery and mechanical systems.

In conclusion, flexible couplings can effectively serve as connectors for both motor-to-shaft and shaft-to-shaft connections, providing essential misalignment compensation and protection for connected equipment in various industrial applications.

editor by CX 2024-03-01

China Standard Kc Series Steel Casting Flexible Sprocket Roller Chain Coupling for Mining Machinery

Product Description

Product Description

Product Parameters

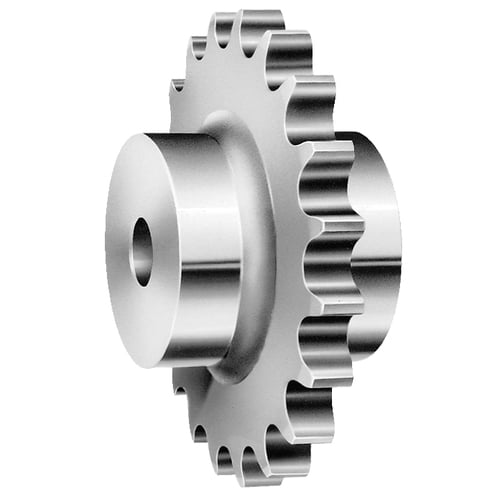

| product | Kc Series Steel Casting Flexible Sprocket Roller Chain Coupling for test benches |

| material | stainless steel , iron , aluminum ,bronze ,carbon steel ,brass etc . |

| size | ISO standard ,customer requirements |

| kind | expansion sleeve Z1/Z2/Z3/Z4/Z5/Z6/Z7/Z8/Z9/Z10/Z11/Z12/Z13/Z14/Z18/Z19 |

| BORE | Finished bore, Pilot Bore, Special request |

| surface treatment | Carburizing and Quenching,Tempering ,Tooth suface high quenching Hardening,Tempering |

| Processing Method | Molding, Shaving, Hobbing, Drilling, Tapping, Reaming, Manual Chamfering, Grinding etc |

| Heat Treatment | Quenching & Tempering, Carburizing & Quenching, High-frequency Hardening, Carbonitriding…… |

| Package | Wooden Case/Container and pallet, or made-to-order |

| Certificate | ISO9001 ,SGS |

| Machining Process | Gear Hobbing, Gear Milling, Gear Shaping, Gear Broaching, Gear Shaving, Gear Grinding and Gear Lapping |

| Applications | Toy, Automotive, instrument, electrical equipment, household appliances, furniture, mechanical equipment,daily living equipment, electronic sports equipment, , sanitation machinery, market/ hotel equipment supplies, etc. |

| Testing Equipment | Rockwell hardness tester 500RA, Double mesh instrument HD-200B & 3102,Gear measurement center instrument CNC3906T and other High precision detection equipments |

workshop & equipment

Production process

Certifications

Our Advantages

1 . Prioritized Quality

2 .Integrity-based Management

3 .Service Orientation

4 .150+ advanced equipment

5 .10000+ square meter factory area

6 .200+ outstanding employees

7 .90% employees have more than 10 year- working experience in our factory

8 .36 technical staff

9 .certificate ISO 9001 , SGS

10 . Customization support

11 .Excellent after-sales service

shipping

sample orders delivery time:

10-15 working days as usual

15-20 working days in busy season

large order leading time :

20-30 working days as usual

30-40 working days in busy season

FAQ

1. why should you buy products from us not from other suppliers?

We are a 32 year-experience manufacturer on making the gear, specializing in manufacturing varieties of gears, such as helical gear ,bevel gear ,spur gear and grinding gear, gear shaft, timing pulley, rack, , timing pulley and other transmission parts . There are 150+ advanced equipment ,200+ excellent employees ,and 36 technical staff . what’s more ,we have got ISO9001 and SGS certificate .

2 .Do you accept small order?

If your order bearings are our standard size, we accept even 1pcs.

3 .How long is the delivery?

A: Small orders usually takes 10-15 working days,big order usually 20-35 days, depending on orders quantity and whether are standard size.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What are the key features to look for when purchasing a flexible coupling?

When purchasing a flexible coupling, several key features should be considered to ensure it meets the specific requirements of the application and provides reliable performance. The following are the key features to look for:

- 1. Type of Coupling: There are different types of flexible couplings available, such as jaw couplings, beam couplings, bellows couplings, disc couplings, and more. Each type has its advantages and limitations, so choosing the right type depends on factors like misalignment compensation needed, torque capacity, and application requirements.

- 2. Material: The material of the coupling is crucial for its durability and performance. Common materials include stainless steel, aluminum, steel, and various elastomers. Select a material that can withstand the environmental conditions, loads, and temperature ranges of the application.

- 3. Size and Dimensions: Ensure that the coupling’s size and dimensions match the shaft sizes and available space in the system. Oversized or undersized couplings may lead to inefficiencies, misalignment, and reduced performance.

- 4. Torque Rating: Consider the maximum torque the coupling can handle to ensure it can transmit the required power without failure or damage.

- 5. Speed Rating: Check the coupling’s maximum rotational speed capability to ensure it can handle the desired operating speed without issues.

- 6. Misalignment Compensation: Different couplings offer varying degrees of misalignment compensation, such as angular, parallel, and axial misalignment. Choose a coupling that can accommodate the expected misalignments in the system.

- 7. Backlash: For precision applications, consider couplings with minimal or zero-backlash to prevent motion inaccuracies and ensure precise positioning.

- 8. Operating Environment: Assess the environmental conditions, including temperature, humidity, dust, and chemical exposure, and select a coupling with suitable resistance to these factors.

- 9. Maintenance: Decide whether maintenance-free couplings or those requiring periodic lubrication align better with the application’s requirements and maintenance schedule.

- 10. Electrical Isolation: If required, choose couplings with electrical isolation features to prevent current flow between connected shafts.

- 11. Dynamic Behavior: Evaluate the coupling’s dynamic performance, including resonance and damping characteristics, to ensure smooth operation under various loads and speeds.

- 12. Application Compatibility: Verify that the selected coupling is suitable for the specific application, such as pumps, compressors, robotics, automation, or other industrial processes.

Summary: When purchasing a flexible coupling, consider factors such as the type of coupling, material, size, torque rating, speed rating, misalignment compensation, backlash, operating environment, maintenance, electrical isolation, dynamic behavior, and application compatibility. Careful consideration of these features will ensure that the coupling meets the demands of the application, provides reliable performance, and contributes to the overall efficiency of the mechanical system.

What are the maintenance intervals and practices for extending the life of a flexible coupling?

Proper maintenance of a flexible coupling is essential to ensure its longevity and reliable performance. The maintenance intervals and practices for flexible couplings may vary depending on the coupling type, application, and operating conditions. Here are some general maintenance guidelines to extend the life of a flexible coupling:

- Regular Inspection: Conduct visual inspections of the coupling regularly to check for signs of wear, damage, or misalignment. Look for cracks, tears, corrosion, or any other visible issues.

- Lubrication: Some flexible couplings may require periodic lubrication to reduce friction and wear. Refer to the manufacturer’s guidelines for the appropriate lubrication type and schedule.

- Alignment Checks: Ensure that the connected shafts remain properly aligned. Misalignment can lead to premature wear and failure of the coupling and other components.

- Torque Monitoring: Monitor the torque levels in the system and ensure they are within the coupling’s rated capacity. Excessive torque can overload the coupling and cause damage.

- Temperature and Environmental Considerations: Ensure that the operating temperatures and environmental conditions are within the coupling’s specified limits. Extreme temperatures, aggressive chemicals, or corrosive environments can impact the coupling’s performance.

- Inspection After Shock Loads: If the system experiences shock loads or unexpected impacts, inspect the coupling for any signs of damage immediately.

- Replace Damaged or Worn Couplings: If any damage or wear is detected during inspections, replace the flexible coupling promptly to avoid potential failures.

- Periodic Re-Tightening: For certain coupling designs, periodic re-tightening of fasteners may be necessary to maintain proper clamping force.

- Follow Manufacturer’s Guidelines: Always follow the maintenance instructions provided by the coupling manufacturer. They can provide specific recommendations based on the coupling model and application.

It is crucial to develop a maintenance plan specific to the application and coupling type. Regularly scheduled maintenance, adherence to recommended practices, and proactive inspection can help identify issues early and prevent costly breakdowns. Additionally, record-keeping of maintenance activities can provide valuable data on the coupling’s performance and aid in future maintenance decisions.

What are the advantages of using flexible couplings in mechanical systems?

Flexible couplings offer several advantages in mechanical systems, making them essential components in various applications. Here are the key advantages of using flexible couplings:

- Misalignment Compensation: One of the primary advantages of flexible couplings is their ability to compensate for shaft misalignment. In mechanical systems, misalignment can occur due to various factors such as installation errors, thermal expansion, or shaft deflection. Flexible couplings can accommodate angular, parallel, and axial misalignment, ensuring smooth power transmission and reducing stress on the connected equipment and shafts.

- Vibration Damping: Flexible couplings act as damping elements, absorbing and dissipating vibrations and shocks generated during operation. This feature helps to reduce noise, protect the equipment from excessive wear, and enhance overall system reliability and performance.

- Torsional Flexibility: Flexible couplings provide torsional flexibility, allowing them to handle slight angular and axial deflections. This capability protects the equipment from sudden torque fluctuations, shock loads, and torque spikes, ensuring smoother operation and preventing damage to the machinery.

- Overload Protection: In case of sudden overloads or torque spikes, flexible couplings can absorb and distribute the excess torque, protecting the connected equipment and drivetrain from damage. This overload protection feature prevents unexpected failures and reduces downtime in critical applications.

- Reduce Wear and Maintenance: By compensating for misalignment and damping vibrations, flexible couplings help reduce wear on the connected equipment, bearings, and seals. This results in extended component life and reduced maintenance requirements, leading to cost savings and improved system reliability.

- Compensation for Thermal Expansion: In systems exposed to temperature variations, flexible couplings can compensate for thermal expansion and contraction, maintaining proper alignment and preventing binding or excessive stress on the equipment during temperature changes.

- Electric Isolation: Some types of flexible couplings, such as disc couplings, offer electrical isolation between shafts. This feature is beneficial in applications where galvanic corrosion or electrical interference between connected components needs to be minimized.

- Space and Weight Savings: Flexible couplings often have compact designs and low inertia, which is advantageous in applications with space constraints and where minimizing weight is crucial for performance and efficiency.

- Cost-Effectiveness: Flexible couplings are generally cost-effective solutions for power transmission and motion control, especially when compared to more complex and expensive coupling types. Their relatively simple design and ease of installation contribute to cost savings.

In summary, flexible couplings play a vital role in mechanical systems by providing misalignment compensation, vibration damping, overload protection, and torsional flexibility. These advantages lead to improved system performance, reduced wear and maintenance, and enhanced equipment reliability, making flexible couplings a preferred choice in various industrial, automotive, marine, and aerospace applications.

editor by CX 2024-02-15

Chain made in China – replacement parts – in Naples Italy Sprocket 125 Oregon Rim Kasete 7 Speed ANSI Standard Catalog Motorcycle 8 Speed Freewheel Cassete Kit Hero Splendor Bike Kobelco Adjustable D5 Bulldoze with ce certificate top quality low price

We – EPG Group the bigge EPT Chain and agricultural gearbox manufacturing facility in China with 5 diverse branches. For more information: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Chain sprocket a hundred twenty five oregon rim kasete 7 speed ansi common catalog motorcycle 8 velocity freewheel cassete kit hero splendor bike kobelco adjustable d5 bulldoze

Manufacturer of Sprocket, Chain sprockets, wheel and sprocket, push sprocket, sprocket wheel, taper lock sprocket, gear sprocket, idle sprocket, motorbike sprocket and stainless metal sprocket, can interchange and exchange with martin measurement sprocket, jt measurement sprockets, did size chain sprocket and so on.

The use of original tools manufacturer’s (OEM) component numbers or trademarks , e.g. CASE® and John Deere® are for reference needs only and for indicating merchandise use and compatibility. Our organization and the detailed substitution parts contained herein are not sponsored, approved, or produced by the OEM.

Best made in China – replacement parts – Chain & sprocket manufacturer : Industrial for replacement of Diamond 80 roller chain in Bukavu Democratic Republic of the Congo 120-1 Standard Roller Chain with ce certificate top quality low price

We – EPG Team the biggest Chain and agricultural gearbox manufacturing unit in China with 5 distinct branches. For a lot more particulars: Cell/whatsapp/telegram/Kakao us at: 0086-13083988828

We examine each and every piece of bearing by ourselves ahead of supply.roller The team is focused on making all variety of regular roller chains and sprockets, gears & gearboxes, these kinds of as conveyor chain & sprockets , stainless metal chain, agricultural chain and has not just bought its items all over china, but also offered a lot more than sixty five% goods to oversees, which includes Europe, The united states, South-east Asia, and it also has set up storage logistics in places like Europe. chains. Conveyor chains, engineered chains, silent chains, and tabletop chains are also available. Other electrical power transmission merchandise contain pillow blocks, conveyor idlers, conveyor pulleys, push shafts, equipment racks, gear reducers, gears, overrunning clutches, motor bases, pulleys, screw conveyors, shaft couplings, sheaves, pace reducers, sprockets, tapered bushings, tensioners, torque limiters, and universal joints. Providers this kind of as bearing reconditioning and repair, ball screw fix, customized deal machining, gearbox restore and overrunning clutch restore providers are available. Roller chains can be utilized in conveyor and equipment production, industrial processing, equipment rebuilding, waste h2o, sand and gravel, device and die, metal, metals and scrap processing industrial purposes. Manufacturer & distributor of roller & wire rope conclude chains. Kinds of chains contain alloy, high tensile transport, higher examination & proof coil chains. Purposes include log chains, cargo lashings, pipe line handing, tailgates, guard rails & switch chains.

ZHangZhoug EPT Chain Co.,Ltd. As the skilled Forklift leaf chaincompany . EPT Chain would like to make very appropriate solutions to all the valued consumers at home and overseas.”

Our business owns far more than 100 sets of advanced and professional manufacturing equipments, EPT and demanding QC program is implemented in each and every approach from substance buying to concluded items packaging. Also, we have handed the ISO9001: 2015 Good quality Management Program Certification.

We feel “Quality is the existence of the business,Delivery is the assure to the custmoers”.And we sincerely hopes to establish get-win organization with abroad and domestic consumers

| ISO Chain No | ANSI No | Pitch | Internal Plate Width | Roller Diameter | Plate Specifics | Pin Detials | Tensile Strength | Typical Tensile Energy | Gross Weight | ||||

| Thickness | Width | diameter | Size | Connection duration | |||||||||

| P(mm) | b1(mm) | d1(mm) | mm | mm | mm | L(mm) | Lc(mm) | Kn | Kn | kg/m | |||

| 04C-1 | 25R-one | six.35 | three.eighteen | three.three | .eighty/.80 | 6.00 | two.31 | 7.9 | eight.four | 3.5 | 4.6 | .fifteen | |

| 06C-1 | 35R-1 | 9.525 | four.seventy seven | five.08 | one.thirty/1.thirty | 9.00 | 3.58 | 12.four | thirteen.17 | 7.9 | 10.eight | .33 | |

| 083-one | 415-one | twelve.seven | 4.seventy six | seven.77 | 1.30/1.00 | nine.70 | three.6 | 11 | twelve.4 | 11.six | 12.6 | .32 | |

| 084-1 | 415H-1 | 12.seven | 4.seventy six | seven.77 | one.fifty/1.fifty | 12.00 | 3.96 | 13.1 | fourteen.five | 15.six | 16.1 | .fifty five | |

| 085-1 | 41R-1 | twelve.7 | six.25 | 7.77 | one.twenty five/1.25 | nine.91 | three.fifty eight | 13.75 | 15 | 6.seven | seven.6 | .forty one | |

| 08A-one | 40R-one | twelve.seven | 7.eighty five | 7.ninety two | one.fifty/1.fifty | twelve.00 | 3.ninety six | 16.six | 17.eight | 14.1 | seventeen.five | .sixty two | |

| 10A-1 | 50R-one | 15.875 | 9.four | 10.16 | two.00/2.00 | 15.09 | five.08 | 20.seven | 22.two | 22.2 | 29.4 | 1.02 | |

| 12A-one | 60R-one | 19.05 | twelve.57 | eleven.91 | two.forty/2.40 | 18.00 | five.94 | 25.nine | 27.7 | 31.8 | 41.5 | one.five | |

| 16A-one | 80R-1 | twenty five.4 | fifteen.75 | 15.88 | three.twenty/3.twenty | 24.00 | seven.ninety two | 32.7 | 35 | 56.7 | sixty nine.4 | two.six | |

| 20A-1 | 100R-1 | 31.75 | eighteen.nine | 19.05 | 4.00/4.00 | 30.00 | 9.fifty three | forty.four | forty four.seven | 88.five | 109.two | 3.ninety one | |

| 24A-1 | 120R-one | 38.1 | twenty five.22 | 22.23 | four.80/4.eighty | 35.70 | eleven.1 | fifty.3 | fifty four.three | 127 | 156.three | 5.62 | |

| 28A-one | 140R-1 | 44.forty five | twenty five.22 | 25.4 | five.60/5.60 | forty one.00 | 12.7 | fifty four.four | fifty nine | 172.4 | 212 | seven.five | |

| 32A-one | 160R-one | fifty.eight | 31.fifty five | 28.58 | 6.forty/6.forty | forty seven.80 | fourteen.27 | sixty four.8 | 69.6 | 226.8 | 278.nine | ten.1 | |

| 40A-1 | 200R-one | 63.five | 37.eighty five | 39.68 | 8.00/8.00 | 60.00 | 19.eighty five | 80.three | 87.two | 353.8 | 431.6 | 16.15 | |

| 48A-one | 240R-one | 76.two | forty seven.35 | 47.63 | 9.50/9.fifty | 72.39 | 23.81 | 95.5 | 103 | 510.3 | 622.5 | 23.two | |

EPT Chain has set up a complete set of quality administration system which is provided with superior inspection and te EPT tools. EPT has been effectively accredited by ISO9002 Quality Management Program, ISO9001 Good quality Administration Technique, API certification, ISO/TS16949:2002 and ISO10012 measurement management program. Entire use has been manufactured of all kinds of advanced techniques and technologies to get to excelsior producing.

Wonderful attention has been paid out on environmental protection and power preserving. The product well shows environmental safety and energy conserving. In 2015, EPT took the direct in gaining ISO14001 environment administration certification and thereafter passed the inspection of clean creation and recycling economic system, successful the title of “ZHangZhoug Eco-friendly Organization”.

“We are often serving our clients with our be EPT merchandise.” EPT will often adhere to it company spirit of being sensible, modern, effective and superb to make the best international chain travel.

Mandy

CEO.

ZHangZhoug EPT Chain Co.,Ltd.

Deal with: #8th Shangbo Street,HangZhou Industrial zone,ZHangZhoug,China

The use of unique products manufacturer’s (OEM) element figures or logos , e.g. CASE® and John Deere® are for reference purposes only and for indicating merchandise use and compatibility. Our business and the outlined replacement components contained herein are not sponsored, accepted, or produced by the OEM.

Standard made in China – replacement parts – in Boston United States Duplex Hub Sprocket 12b-1 for Motorcycle with ce certificate top quality low price

We – EPG Team the bigge EPT Chain and agricultural gearbox factory in China with 5 different branches. For far more information: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Solution specification

one.Material:C 45# metal ,stainless steel or EPT required materials.

2.Sprockets can be produced in accordance the customer’s drawings

3.Warmth treatment: Hardening and Tempering, High Frequency Quenching, Carburizing Quenching and so on in accordance the specifications..

four. Inspection: All products are checked and analyzed thoroughly throughout each operating process and soon after production will be reinspected.

About us

HangZhou EPT Sprocket Co., Ltd. is a specialist maker of numerous sprocket wheels, stainless steel sprocket wheels, non-standard sprocket wheels, huge pitch sprocket wheels, coupling sprocket wheels, spur gears, timing belt wheels, gear racks, umbrella Gear, worm equipment, shaft, sleeve and EPT transmission parts makers. And in accordance to consumer drawings, samples, dimension processing personalized generation. The organization integrates style R & D, production and income. In accordance with strict creation, inspection and high quality standards, the organization has proven a complete high quality technique, production process and ideal high quality handle. The firm’s sprocket products are of large good quality, balance and sturdiness.

The company now has eighty sets of a variety of large-precision CNC lathes, gear hobbing machines, equipment shapers, tempering furnaces, quenching tools, gantry planers, universal milling, sawing equipment, vertical broaching devices, hydraulic equipment and EPT processing tools, with an once-a-year creation ability of 2 million items . Carburizing and quenching, nitriding, quenching and EPT heat treatment, surface area blackening, galvanizing, electrophoresis, and so forth. At the identical time, it also has substantial-precision tests products such as: Rockwell hardness tester, Vickers hardness tester, metallographic microscope, picture measuring instrument, Magnetic particle flaw detectors, etc. The items produced are broadly utilized in metallurgy, metal, chemical, textile, agricultural machinery, 3-dimensional garages, packaging equipment, chemical equipment, pharmaceutical machinery, industrial and mining machinery and EPT industries. The solution indicators fulfill the demands of importing related products and are exported to Hong Kong and ZheJiang , Southea EPT Asia, Europe, The usa, the Middle Ea EPT and EPT locations, and are deeply trustworthy and praised by buyers.

FAQ

Q: Are you investing organization or maker ?

A: We are factory.

Q: How lengthy is your shipping and delivery time?

A: Normally it is 5-10 days if the products are in inventory. or it is fifteen-twenty days if the products are not in stock, it is according to quantity.

Q: Do you provide samples ? is it cost-free or added ?

A: Yes, we could supply the sample for cost-free demand but do not shell out the co EPT of freight.

Q: What is your phrases of payment ?

A: Payment 30%TT in advance. 70% T/T just before shippment.

Q:What`s the MOQ of your products?

A:1 established,we can also deal with the sample buy. and the huge-amount.

The use of first products manufacturer’s (OEM) part numbers or logos , e.g. CASE® and John Deere® are for reference purposes only and for indicating item use and compatibility. Our organization and the shown substitution components contained herein are not sponsored, accepted, or created by the OEM.

Best China manufacturer & factory China manufacturer High frequency quenching standard roller chain sprocket With high quality best price

Due to our wide product range and rich experiences in this industry, we are confident to provide our customers flexible and diversified services.

Overview

Quick Details

- Applicable Industries:

-

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, farms, Energy & Mining

- Product name:

-

Roller Chain Sprocket

- Application:

-

Transmission Machine

- Color:

-

Nature

- Processing:

-

Hobbing

- Packing:

-

Carton

- Type:

-

TypeA/TypeB/TypeC

- Heat treatment:

-

High frequency quenching

- Quality:

-

Top High

- Standard or Nonstandard:

-

Standard

- MOQ:

-

5

Supply Ability

- Supply Ability:

- 5000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- plastic bags +cartons+wodden case

- Port

- TIANJIN PORT/SHANGHAI PORT/QINGDAO PORT

-

Lead Time

: -

Quantity(Bags) 1 – 100 101 – 300 >300 Est. Time(days) 7 15 To be negotiated

Online Customization

EPG offer widest range of gearbox and speed reducers, conveyor chains and transmission parts like gear, sprocket, racks, pulley, shaves and taper bushes etc for various applications

Sprocket

|

product name |

sprocket |

||||||

|

Standard |

ANSI,DIN,ISO |

||||||

|

Surface treatment |

Zinc Plating, Chrome plated, Black oxide Treatment, Spray Paint, Mirror Finish, Sand-blasting and so on. |

||||||

|

Heat treatment |

Hardening and Tempering, High Frequency Quenching, Carburizing Quenching and so on. |

||||||

|

Material |

C45,stainless steel,POM,A3,plastic and so on |

||||||

|

Sprocket type |

Type A sprockets :Plate (without Hub) |

||||||

|

Type B sprockets:One side with hub |

|||||||

|

Type C sprockets: Double side with hub |

|||||||

|

Finished bore sprockets:With the inner hole ,keyway and screw |

|||||||

|

Sprocket size |

ANSI: 25/35/41/40/50/60/80/100/120/140/160/180/200/240 |

||||||

|

DIN/ISO:04C/06C/085/08A/10A/12A/16A/20A/24A/28A/32A/36A/40A/48A |

|||||||

|

DIN/ISO:04B/05B/06B/08B/10B/12B/16B/20B/24B/28B/32B/40B/48B/56B/64B/72B |

|||||||

Different type sprocket

Single direction FREE WHEEL (RA) Single direction PAWL torque limiter (SW) Disc torque limiter clutch with spring (FFT)

simplex A

simplex B

simplex C

duplex A

duplex B

duplex C

triplex A

triplex B

triplex C

Processing

Application

Sprocket catalogue

Packing & Delivery

Payment

Main product

roller chain

sprocket

gear

timing belt pulley

timing belt

gear rack

taper bush

liner rEPG major production is of farming 15-500 horsepower tractor supporting machinery, mechanical cultivation, harvesting machinery and accessories. ail and block

motor sprocket

Company Profile

HangZhou EPG – The biggest transmission parts manufacuturer in China Electrical Equipment Co.,Ltd was founded in HangZhou in 2008 and is a professional manufacturer and exporter that is concerned with the design, development and production.With detailed requirments, we can also develop your special designed product. Our product range includes all kinds of helical gear, spur gear, bevel gear, gear rack, worm gear, sprockets,chains, bearings.Keeping in mind that good service is the key to cooperating with clients, we strive to meet high quality standards, offer competitive prices and ensurWhen drive systems with high precision, reliability and extensive functionality are required to fit in small spaces, EPG supplies the necessary technology – either as standard solutions or individualized designs.e prompt delivery. In this way, our products have continued to gain market acceptance and customers satisfaction over the past few years. We are aiming to meet the demands of the clients around the world..If you are interested in any of our products or would like to discuss a potential order, please feel free to contact us. We are looking forward to developing successful business relationships with new clients around the world in the future.