Product Description

Product Description

Product Parameters

| product | Star Elastic with Enlarged Shaft Hole Flexible Coupling for Machine tools |

| material | stainless steel , iron , aluminum ,bronze ,carbon steel ,brass etc . |

| size | ISO standard ,customer requirements |

| BORE | Finished bore, Pilot Bore, Special request |

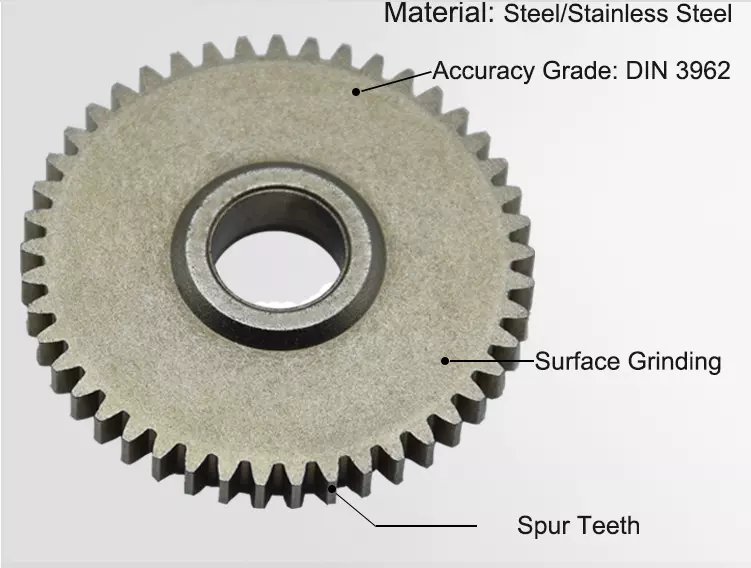

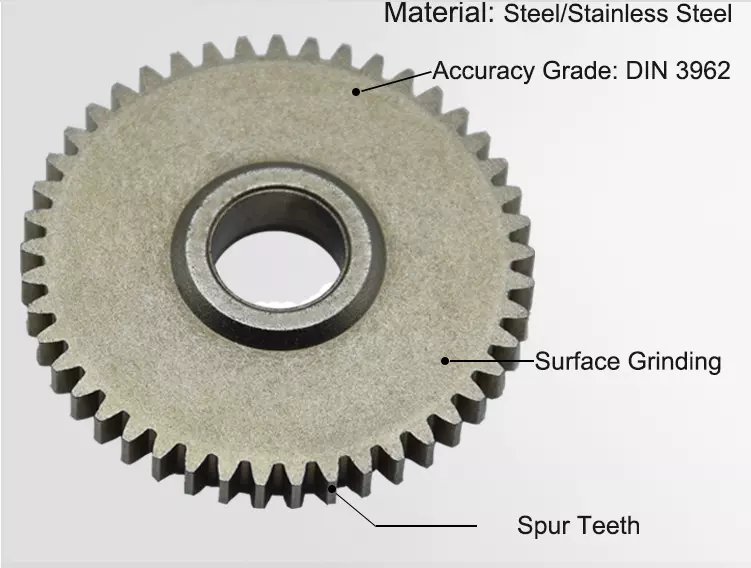

| surface treatment | Carburizing and Quenching,Tempering ,Tooth suface high quenching Hardening,Tempering |

| Processing Method | Molding, Shaving, Hobbing, Drilling, Tapping, Reaming, Manual Chamfering, Grinding etc |

| Heat Treatment | Quenching & Tempering, Carburizing & Quenching, High-frequency Hardening, Carbonitriding…… |

| Package | Wooden Case/Container and pallet, or made-to-order |

| Certificate | ISO9001 ,SGS |

| Machining Process | Gear Hobbing, Gear Milling, Gear Shaping, Gear Broaching, Gear Shaving, Gear Grinding and Gear Lapping |

| Applications | Toy, Automotive, instrument, electrical equipment, household appliances, furniture, mechanical equipment,daily living equipment, electronic sports equipment, , sanitation machinery, market/ hotel equipment supplies, etc. |

| Testing Equipment | Rockwell hardness tester 500RA, Double mesh instrument HD-200B & 3102,Gear measurement center instrument CNC3906T and other High precision detection equipments |

workshop & equipment

Production process

Certifications

Our Advantages

1 . Prioritized Quality

2 .Integrity-based Management

3 .Service Orientation

4 .150+ advanced equipment

5 .10000+ square meter factory area

6 .200+ outstanding employees

7 .90% employees have more than 10 year- working experience in our factory

8 .36 technical staff

9 .certificate ISO 9001 , SGS

10 . Customization support

11 .Excellent after-sales service

shipping

sample orders delivery time:

10-15 working days as usual

15-20 working days in busy season

large order leading time :

20-30 working days as usual

30-40 working days in busy season

FAQ

1. why should you buy products from us not from other suppliers?

We are a 32 year-experience manufacturer on making the gear, specializing in manufacturing varieties of gears, such as helical gear ,bevel gear ,spur gear and grinding gear, gear shaft, timing pulley, rack, , timing pulley and other transmission parts . There are 150+ advanced equipment ,200+ excellent employees ,and 36 technical staff . what’s more ,we have got ISO9001 and SGS certificate .

2 .Do you accept small order?

If your order bearings are our standard size, we accept even 1pcs.

3 .How long is the delivery?

A: Small orders usually takes 10-15 working days,big order usually 20-35 days, depending on orders quantity and whether are standard size.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

How do flexible couplings handle shaft misalignment in rotating equipment?

Flexible couplings are designed to handle shaft misalignment in rotating equipment, providing several key features that allow them to accommodate misalignment effectively. Here’s how they work:

- Angular Misalignment: Flexible couplings can handle angular misalignment, which occurs when the axes of the connected shafts are not perfectly aligned. The coupling’s flexible elements allow for slight angular deviation, ensuring that the torque can still be transmitted smoothly between the shafts.

- Parallel Misalignment: Parallel misalignment occurs when the connected shafts are not perfectly in line but run parallel to each other. Flexible couplings can compensate for this misalignment by utilizing their ability to flex or slide, allowing the shafts to remain connected while maintaining rotational integrity.

- Axial Misalignment: Axial misalignment refers to the situation where the connected shafts have a slight axial displacement. Some flexible couplings have specific designs to handle axial misalignment, allowing for limited movement along the axial direction without compromising the connection between the shafts.

- Double Flexing: Certain types of flexible couplings, such as the double-flexing couplings, can accommodate both angular and parallel misalignments simultaneously. These couplings use two sets of flexible elements to achieve this capability, providing a higher degree of misalignment compensation.

Overall, the flexibility of the coupling’s material and design allows it to bend, flex, or slide in response to the misalignment, reducing the stress on the connected equipment and ensuring smooth power transmission. By accommodating misalignment, flexible couplings help prevent premature wear, reduce vibration, and extend the service life of the rotating equipment.

How does a flexible coupling handle misalignment in large rotating equipment?

Flexible couplings are designed to accommodate various types of misalignment in large rotating equipment, ensuring smooth and efficient power transmission while minimizing stress on connected components. Here’s how flexible couplings handle different types of misalignment:

- Angular Misalignment: Angular misalignment occurs when the axes of the two connected shafts are not collinear and form an angle. Flexible couplings can handle angular misalignment by allowing the coupling elements to flex and move slightly, thus accommodating the angle between the shafts. The flexible elements, often made of elastomeric materials or metallic membranes, can bend and twist to compensate for angular misalignment, ensuring that the coupling remains engaged and transfers torque effectively.

- Parallel Misalignment: Parallel misalignment, also known as offset misalignment, happens when the two shafts are not perfectly aligned along their axes, resulting in a lateral shift. Flexible couplings can handle parallel misalignment through their ability to move radially, allowing the flexible elements to adjust and take up the offset. This capability prevents excessive side loads on the shafts and bearings, reducing wear and increasing the lifespan of the equipment.

- Axial Misalignment: Axial misalignment occurs when there is a linear displacement of one shaft relative to the other, either toward or away from the other shaft. Some flexible couplings, such as certain types of flexible disc couplings, can accommodate a limited amount of axial misalignment. However, for large axial movement, other types of couplings or special designs may be required.

The flexibility of the coupling elements allows them to act as a buffer between the shafts, dampening shocks, vibrations, and torsional forces caused by misalignment or other dynamic loads. This helps protect the connected equipment from damage and enhances the overall performance and reliability of the rotating system.

In large rotating equipment, where misalignment is more common due to thermal expansion, foundation settling, or other factors, flexible couplings play a critical role in maintaining smooth operation and reducing stress on the machinery. However, it is essential to choose the appropriate type of flexible coupling based on the specific requirements of the application and to regularly inspect and maintain the coupling to ensure optimal performance and longevity.

What are the maintenance requirements for flexible couplings?

Maintenance of flexible couplings is essential to ensure their reliable and efficient performance over their service life. Proper maintenance helps prevent premature wear, reduces the risk of unexpected failures, and extends the lifespan of the couplings. Here are some key maintenance requirements for flexible couplings:

- Regular Inspection: Perform regular visual inspections of the flexible couplings to check for signs of wear, damage, or misalignment. Look for cracks, tears, or any other visible issues in the coupling components.

- Lubrication: Some flexible couplings, especially those with moving parts or sliding surfaces, may require periodic lubrication. Follow the manufacturer’s recommendations regarding the type and frequency of lubrication to ensure smooth operation.

- Alignment Checks: Misalignment is a common cause of coupling failure. Regularly check the alignment of the connected shafts and adjust as necessary. Proper alignment reduces stress on the coupling and improves power transmission efficiency.

- Torque Monitoring: Monitoring the torque transmitted through the coupling can help detect any abnormal or excessive loads. If the coupling is subjected to loads beyond its rated capacity, it may lead to premature failure.

- Environmental Protection: If the couplings are exposed to harsh environmental conditions, take measures to protect them from dust, dirt, moisture, and corrosive substances. Consider using protective covers or seals to shield the couplings from potential contaminants.

- Temperature Considerations: Ensure that the operating temperature of the flexible coupling is within its designed range. Excessive heat can accelerate wear, while extremely low temperatures may affect the flexibility of certain coupling materials.

- Replace Worn or Damaged Parts: If any components of the flexible coupling show signs of wear or damage, replace them promptly with genuine replacement parts from the manufacturer.

- Manufacturer’s Guidelines: Follow the maintenance guidelines provided by the coupling manufacturer. They often include specific maintenance intervals and procedures tailored to the coupling’s design and materials.

- Training and Expertise: Ensure that maintenance personnel have the necessary training and expertise to inspect and maintain the flexible couplings properly. Improper maintenance practices can lead to further issues and compromise the coupling’s performance.

By adhering to these maintenance requirements, you can maximize the service life of the flexible couplings and minimize the risk of unexpected downtime or costly repairs. Regular maintenance helps maintain the efficiency and reliability of the coupling in various industrial, automotive, and machinery applications.

editor by CX 2024-03-18

China Roller chain and sprocket manufacturer Automatic system plast roller chain guide in Thiruvananthapuram India Wallpaper Heat Shrink Wrapping Machine Packaging Machine with ce certificate top quality low price

We – EPG Group the biggest Chain and agricultural gearbox manufacturing facility in China with 5 distinct branches.

we source chromed bar and tubes for hydualic and pheumatic cylinders, pto shaft, agricultural gearboxes etc. EPG The new merchandise contain a sequence of high-tech and high quality chains and sprockets and gears, these kinds of as chains and gearboxes for agricultural machineries, metallurgical chains, escalator action-chains, high-speed tooth chains, timing chains, self-lubrication chains, amid which have kind high velocity tooth chain for automobile branch dynamic box and aerial chains fill in the blanks of chain in China. is a major provider of high quality, expense-successful energy transmission elements. As our solution lines keep on to expand to meet our customer’s demands, our dedication to personalized buyer service and on-time delivery continues to be 2nd to none. We support a nationwide base of Industrial Distributors, and Authentic Products Manufacturers as effectively as Agricultural Gear Makers and Wholesalers. Located in Memphis, TN we are at the center of 1 of the biggest distribution hubs in the region and with our extensive inventory levels and unrestricted delivery possibilities, we are capable to offer our buyers with precise on-time deliveries. Description:

Gorgeous equipment, Secure top quality, Safety,strength preserving, patented goods, domestic initiative, software to the POF PVC PP film thermal shrink packaging influence is perfect.

Characteristics:

one.Look and knot design and style in accordance with national stHangZhourds, the fuselage utilizes fingerprint resistant sheet manufacturing right after spray remedy.

2.Management panel using programming system, 12V DC input , button swap , digital show.

3. Transmission utilizing 24v DC Motor speed management using variable frequency technology -9 file adjustment.

4.The conveyor belt can be used wire mesh belt, chain roller, Teflon mesh belt 3.

five.Heating using 600W 220V far infrared quartz heating tube.

6.Temperature manage using high precision intelligent temperature handle method . up and down temperature independent regulation.

seven.Sizzling air circulation employing 220V 60W 2200 to the extended axis motor with wind wheel.

8.The bracket can be disassembled , and the peak of the bracket can be altered.

| L SEALER | FQL 450 A | SHRINK TUNNEL | BSN 4571C |

| VOLTAGE | 220/fifty-60HZ | VOLTAGE | 380v fifty-60HZ |

| Electrical power | one.35KW | Energy | 9KW |

| AIR Force: | five-seven | TUNNEL Dimensions(L*W*H) | 1200*400x200mm |

| Ability | fifteen-30bags/min | Solution Dimension(W*H) | 350x150mm |

| Product MAX SIZE L+H(H<150mm) | <500mm | EPT Pace | -15m/min |

| Item MAX Size W+H(H<150mm) | < 400mm | Substance | CHAIN, TEFLON |

| SEALING Size | 550*450mm | CONVEYING LOAD | 20kg max |

| Device Dimension (L*W*H) | 1650*800*1450mm | Equipment Size (L*W*H) | 1600x560x660mm |

| Weight | 300KG | Weight | 80kg |

| Application: | POF.PE, | Software: | PE.POF |

The use of first tools manufacturer’s (OEM) portion numbers or emblems , e.g. CASE® and John Deere® are for reference purposes only and for indicating solution use and compatibility. Our organization and the shown substitution areas contained herein are not sponsored, approved, or manufactured by the OEM.

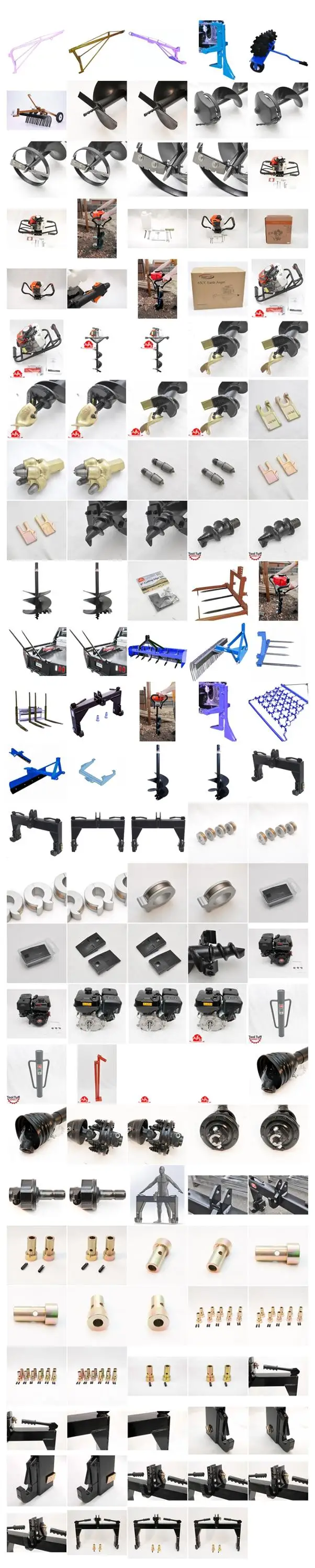

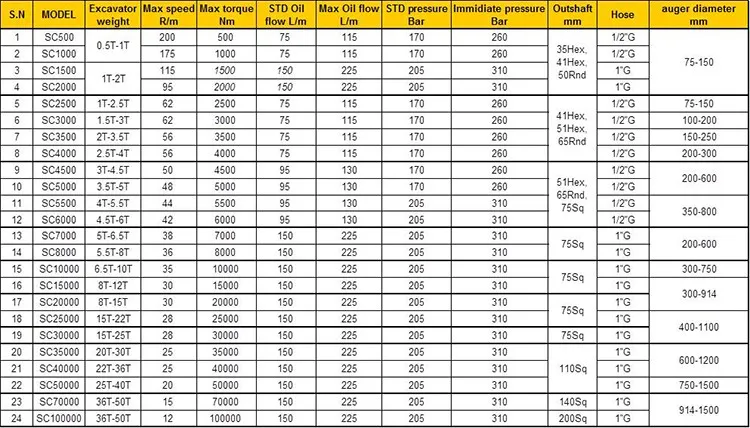

High qualtiy best price hydraulic auger drill drive for mini piling machine Torque by excavator supplier factory manufacturer & exporter in China

Overview

Quick Details

Condition: :

New

Warranty: :

1.5 years

Applicable Industries: :

Manufacturing Plant, OEM

There is a technical center of province level, EPG academician working station, experiment station for EPG post doctors, and national 863 program set up in EPG group. With these platforms and strong technical ability, the more than 400 technicians have developed all variety of special high precise and high strength products, conducted mold programs for key components in the car and national industry revitalizing program, resulting more than 5000 developed over, among which 33 items are autonomous patent technology with 4 patent approved . After Warranty Service: :

Online support

Local Service Location: :

none, United States

Showroom Location: :

none

Type: :

Bearing

Use: :

Cultivators

Place of Origin:Zhejiang, China Brand Name: :

OEM

condition: :

new

Suitable: :

1-50 ton excavator,crane ,skid steer loader

auThe high precise CNC equipment, such as Slow-feeding wire-cut machine, jig grinding machine and electric discharge machine, ensures the top quality precision of mould processing, with the high efficient and environmental protection acid rolling line being the largest raw material converting equipment in the field in china; The wildly use of automatic milling machine, high-speed automatic feeding punch, high speed automatic rolling One aspect of our application consulting is that we have been collecting and combining the experience in chain and sprocket applications in various areas for decades. This is particularly interesting for us whenever customers approach us with some exceeding and challenging requirements.and assembling machine guarantees the high quality and efficiency of components and chain making. ger diameter: :

75-1500mm

Depth: :

20M

STD oil flow: :

75L/M

STD pressure: :

170 bar

outshaft: :

41/51HEX, 65 Rnd,75Squ

Color: :

blue or black

Item: :

drill dirt auger bit

Supply Ability

Supply Ability: : 1000 Set/Sets per Month

Packaging & Delivery

Packaging Details: BOX Port: QINGDAO,DALIAN, SHANGHAI, NINGBO

Online Customization

hydraulic auger drill drive for mini piling machine Torque by excavator

Product Description

Earth Drills are renowned throughout the world for being the best augur system available. A large range of models are available to suit any machine and hole boring task from the smallest fencing job through to major piling works. With a revolutionary gearbox and non-dislodgement shaft, the EPG Earth Drill is built to out-perform and outlast, turning your machine into a truly universal piece of equipment.

Why we choose this earth auger?

It is obviously that earth auger is more efficient than manual work. Besides, using our product is safer than manual work. The hole which dig by the earth auger is more beautiful than man did.

Features & Benefits

– Non-dislodgment shaft.

– Epicyclic Gearbox

– Hose & Coupler options

– High quality hydraulic motor

– Forged hood ears

– Shock-lock tooth locking system

– Augers from 75mm to 1200mm

– new earth drills

Specification

Auger Drive

1.Forged hoods ears: Deal with the heavy strain of daily use. Contact surface wider and safer.

2.American Motor: Developing the most reliable wear parts.

3.ERICYLIC gearbox: Unique planetary gearbox. Multiplied output torque. Extreme efficiency.

4.NON-dislodgement shaft: Assembled top down locked into earth drill house. Never fall out. Provided a safer environment.

5.18 Month After-sales service for auger drive.

drill dirt auger bit Soil Auger Drill Bit Earth Soil Auger Drill Machine

How to choose the most suitable type?

Related spare parts

Our auger teeth have patented unique design.Different teeth for different earth condition.

With those, I believe it is no problem to dig your dream hole.

more auger photos

Factory & Packaging

FAQ

Q: HOW CAN I CHOOSE THE SUITABLE EARTH DRILL?

A:PLEASE REFER TO BELOW QUESTIONS:

- 1. Brand and model of Excavator/Backhoe/Skid Steer loader?

- 2. Diameter of hole to be drilled?

- 3. Depth of hole to be drilled?

- 4. Ground type to be drilled?

Once you have answered the above you can easily make the correct choice.

Q: DO I NEED TO PURCHASE SPARE PARTS WHEN ORDERING AN EARTH DRILL?

A: It is not necessary to purchase spare parts for the Planetary Drive as this is a sealed unit, however it is important to follow the service schedule as outlined in the operators manual. It is advisable to purchase spare wearing parts (teeth and Pilots).

Q: CAN THE EARTH DRILL FIT A VARIETY OF MACHINES?

A: Yes, as long as the carrier’s specifications agree with the parameters of the Earth Drill as outlined in our catalogue.

Q: HOW DO I FIT THE EARTH DRILL TO MY MACHINE?

A: There are four types of mounting linkage available;

- Double Pin Hitch: to be used with excavators fitted with quick couplers.

- Double Pin Cradle hitch: also to be used with excavators fitted with quick hitch, in addition the Cradle hitch can be used to stabilise the Earth Drill whilst travelling around the site and also to aid in the clearing of spoil from the auger.

Q: WHAT CAN I DRILL?

A: There are 3 types of cutting teeth available,

1.Earth and Clay Teeth: Suitable for drilling earth and clay.

2.Tungsten Teeth: Suitable for drilling hard and abrasive ground.

3.Rock Teeth: Suitable for drilling soft, fractured, rock.

Q: HOW DEEP CAN I DRILL?

A: There are extensions available for every Earth Drill however maximum drilling depth depend on the following conditions;

- Diameter of hole to be drilled

- Depth of hole to be drilled

- Type of parent machine to be used

- Ground type to be drilled

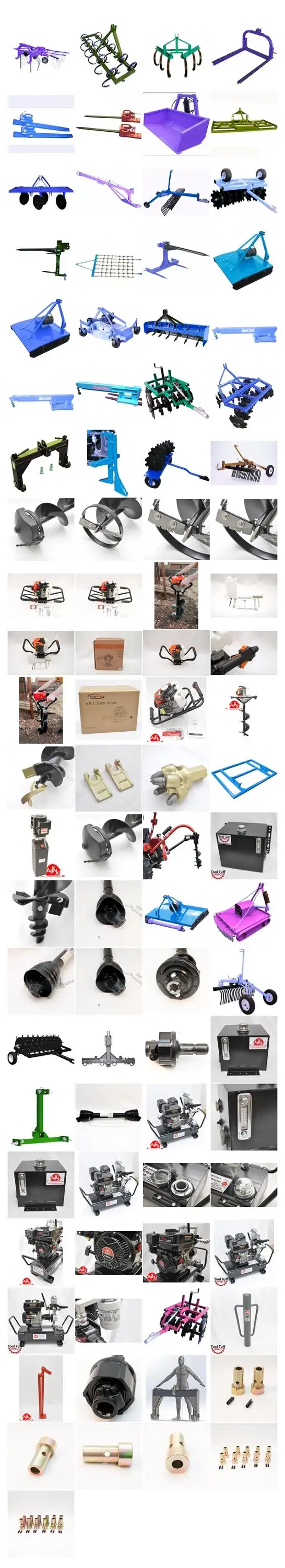

Other attachments

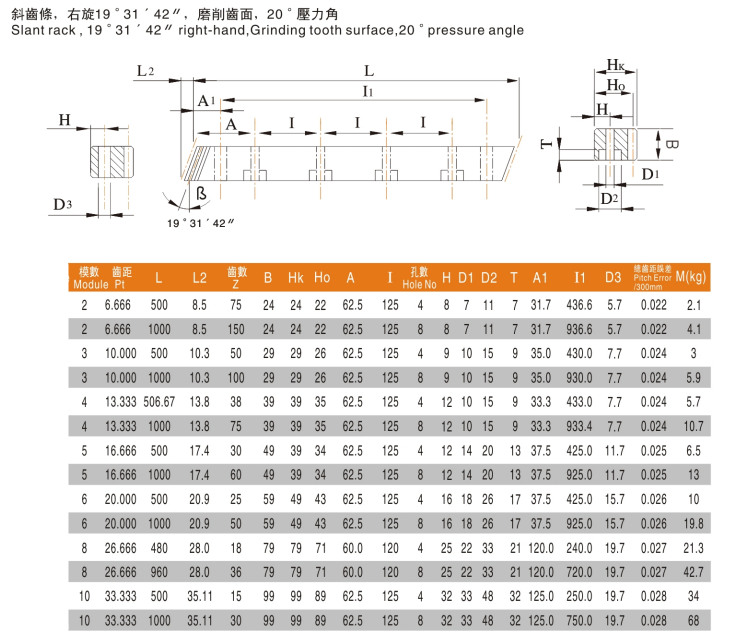

Best China manufacturer & factory China manufacturer High precision Din6 Laser cutting machine helical gear rack With high quality best price

our products are selling well in the American, European, South American and Asian markets. a specialized supplier of a full range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

- Applicable Industries:

-

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, farms, Construction works , Energy & Mining, agricultural machiner

- Product name:

-

Helical Gear Rack

- Color:

-

Nature Color

- Application:

-

Industry Machinery

- Precision grade:

-

Din6

- Surface treatment:

-

ground

- Hardness:

-

40-50 Degree HRC

- Standard:

-

standard

- Right hand angle:

-

19°31’42”

- Pressure:

-

20 Degree

- Sides ground:

-

Included

Supply Ability

- Supply Ability:

- 10000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- wooden/ carton

- Port

- TIANJIN PORT

-

Lead Time

: -

Quantity(Bags) 1 – 2 3 – 100 >100 Est. Time(days) 3 10 To be negotiated

Online Customization

EPG – one of the biggest transmisison suppliers in China. Every process, every section, every function in EPG is demanded to be done one step following another, carefully and cautiously, from material selection, reformation to manufacturing accessories, from components heat treatment to automatic assembly, from quality control to product inspection and testing and from order dealing to after sales service.”We are always serving our customers with our best products.” EPG will always adhere to it enterprise spirit of being practical, innovative, efficient and excellent to make the top international transmission drive.

Product Description

specification

Apply to gear

Close up of shear pin which will shear in half if the implement is subject to sufficient resistance Shear pin: the shear pin shaft I use for the chipper/shredder. The driven end yoke is actually two pieces with a shear pin or bolt that holds the two pieces as one during operation. Should the equipment encounter a sudden stop the pin will take the shock and “shear off” preventing any driveline damage.

|

product name |

helical gear |

|

brand |

HRSY |

|

teeth profile |

helical |

|

precision |

DIN6 |

|

left hand angle |

19°31’42’’ |

|

treatment of teeth OUR HIGH-END SEGMENT: FINDING THE BEST SOLUTION FOR THE CUSTOMER The high-end segment often requires customized solutions. In these cases, we provide you with in-depth consulting in order to devise a common solution to meet your requirements. Only then do we get down to the actual work. |

grinding |

Gear rack catalogue

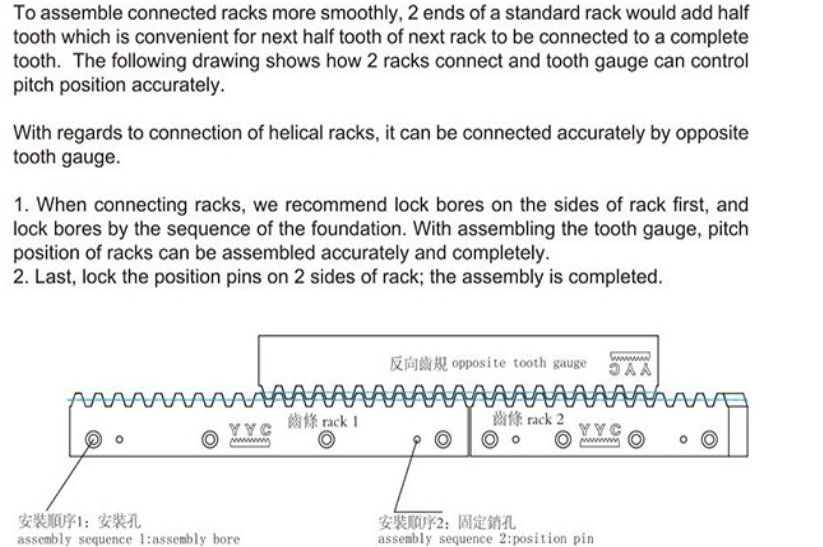

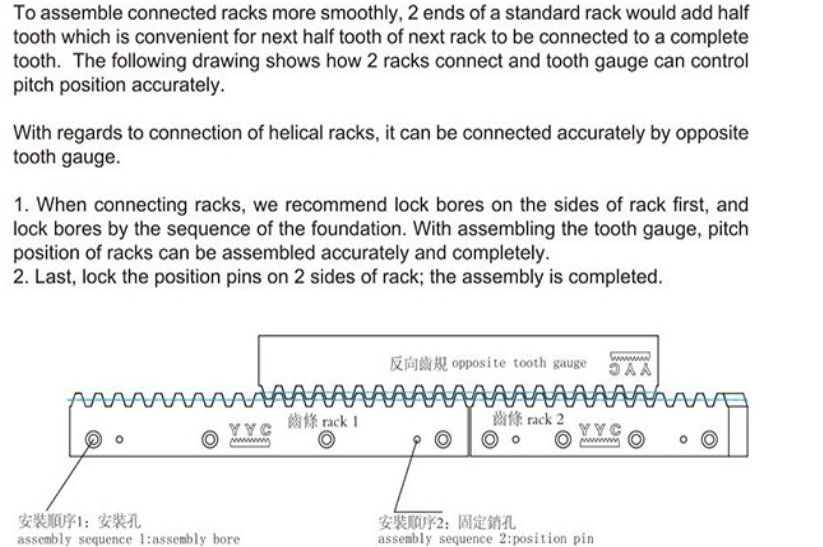

How to install gear rack

Application

Packing & Delivery

Payment & Shipping

Main product

Company introduce&photo

HangZhou EGP Electrical Equipment Co.,Ltd was founded in HangZhou in 1997 and is a professional manufacturer and exporter that is concerned with the design, development and production.With detailed requirments, we can also develop your special designed product. Our product range includes all kinds of helical gear, spur gear, bevel gear, gear rack, worm gear, sprockets,chains, bearings.Keeping in mind that good service is the key to cooperating with clients, we strive to meet high quality standards, offer competitive prices and ensure prompt Our products are selling well in Chinese markets and some products sold in international markets are well received by Chinese and foreign clients at home and abroad.delivery. In this way, our products have continued to gain market acceptance and customers satisfaction over the past few years. We are aiming to meet the demands of the clients around the world..If you are interested in any of our products or would like to discuss a potential order, please feel free to contact us. We are looking forward to developing successful business relationships with new clients around the world in the future.

Made manufacturer China in Thrissur India in Shenzhen Alloy Pulley Timing Pulley for Machine with top quality

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears factory in China with 5 different branches. For more details: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Product Description:

Htd Timing Belt Pulley Type S2m Gear for Laser Cutting Bed

Main Features:

1. OEM/ODM tooth number from 14 to 72 timing pulley

2. Material can be designed by customer requirement

3. High torque series S2M S3M S5M S8M P2M P3M P5M P8M

4. Normal torque series MXL XL L H

5. High precision drive series 2GT 3GT 5GT 8YU

6. Light load drive series T5 T10

7. Heave load drive series AT5 AT10

8. Clamping Timing Pulleys S3M S5M S8M

| Type | Timing pulley adapt to 1/4 inch, 5/16 inch, 3/8 inch, 12 inch belt. |

| Specification | Standard or Custom made |

| Material | Stainless steel,,brass, carbon steel, aluminum, and so on. |

| Machining Process | Gear Hobbing, Gear Milling, Gear Shaping, Gear Broaching,Gear Shaving, Gear Grinding and Gear Lapping |

| Surface Treatment | Zn-plating, Ni-plating, Cr-plating, Tin-plating, Copper-plating, the wreath oxygen resin spraying, black oxide coating, painting, powdering, color zinc-plated,blue black zinc-plated, silver plating,anodizing etc. |

| Producing Equipment | CNC machine , automatic lathe machine,stamping machine,CNC milling machine,rolling machine, lasering, tag grinding machine etc. |

| Management System | ISO9001 – 2008 |

| Testing Equipment | Projecting apparatus, Salt Spray Test, Durometer, and Coating thickness tester, 2D projector |

Shape Selection:

Pulley Production Workshop and Application:

| Applications | Toy, Automotive, instrument, electrical equipment, household appliances, furniture, mechanical equipment,daily living equipment, electronic sports equipment, , sanitation machinery, market/ hotel equipment supplies, etc. |

Our Company:

HangZhou Hefa Gear EPT Co.,L EPT established in 2009, is a professional manufacture engaged in development, production, sales and service of timing pulley, precise spur gears, helical gears, bevel gear, worm& worm gear and so on. We located in HangZhou with convenient transposition excite. Hefa Gear EPT dedicated to strict quality control and thoughtful customer service. Our experienced staffs are always available to discuss your requirements, and fulfill your satisfaction.

Production process: Molding Cutting, Gear Hobbing, Gear Milling, Gear Shaping, Gear Broaching,Gear Shaving, Gear Grinding and Gear Lapping.

Inspection:

Hefa Gear EPT dedicated to strict quality control.” Focus and Professional on the Development of EPT Field” this is Hefa Gear EPT target. Work step by step, Hefa always provide success solution in precise conveyor field. Offering be EPT price, super service and regular delivery are always our priorities.

Packaging, Stock and Delivery:

| Packaging | Polyethylene bag or oil paper for each item; Pile on carton or as customer’s demand |

| Delivery of Samples | By DHL, Fedex, UPS, TNT, EMS |

| Lead time | 10-15 working days as usual, 30days in busy season, it will based on the detailed order quantity. |

FAQ:

| Main Markets? | North America, South America, EPT Europe , We EPT Europe , North Europe, South Europe, Asia |

| How to order? | * You send us drawing or sample |

| * We carry through project assessment | |

| * We give you our design for your confirmation | |

| * We make the sample and send it to you after you confirmed our design | |

| * You confirm the sample then place an order and pay us 30% deposit | |

| * We start producing | |

| * When the goods is done, you pay us the balance after you confirmed pictures or tracking numbers. | |

| * Trade is done, thank you!! |

Advantages:

- High temperature resistance.Self lubrication.Wear resistance.Flame retardant properties.

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears factory in China with 5 different branches. For more details: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

The use of original equipment manufacturer’s (OEM) part numbers or trademarks , e.g. CASE® and John Deere® are for reference purposes only and for indicating product use and compatibility. Our company and the listed replacement parts contained herein are not sponsored, approved, or manufactured by the OEM.

Textile manufacturer China in Bandung Indonesia Machine Parts Caged Wire Jump Preventer Caged CeraEPT Pulley with top quality

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears factory in China with 5 different branches. For more details: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Textile Machine Parts Caged Wire Jump Preventer Caged Ceramic Pulley (NT004)

Caged ceramic pulley is applicable for wire jump preventing during winding.

The middle ceramic roller is made by precise polishing and matched with high-speed bearing so that jump during winding can be minimized to ensure the tension stability.

| Place of Origin: | Xihu (We EPT Lake) Dis. Guan China |

| Brand Name: | KIMCHEN |

| Model: | NT004 |

| Material: | 99%AL2O3 with steel ball |

| Function: | Prevent the wire jumping out |

| Polish: | Fine Polish degree Ra0.2 |

| Bearing: | High speeding bearing |

| Color: | Pink & Red |

| Screw Dia: | M2 |

| Weight: | 4g |

| Minimum Order Quantity: | 100 Pcs |

| Packaging Details: | Carton With Foam |

| Delivery Time: | 3 working days |

| Payment Terms: | T/T, Western Union, Money Gram, Paypal |

| EPT Ability: | 50,000pcs per month |

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears factory in China with 5 different branches. For more details: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

The use of original equipment manufacturer’s (OEM) part numbers or trademarks , e.g. CASE® and John Deere® are for reference purposes only and for indicating product use and compatibility. Our company and the listed replacement parts contained herein are not sponsored, approved, or manufactured by the OEM.

China China best factory manufacturer Wholesale industrial transmission machine part S4.5 timing belt

Our items are applied in numerous fields.

Overview

Quick Particulars

- Applicable Industries:

-

Developing Materials Outlets, Producing Plant, Machinery Restore Stores, Food & Beverage Factory, farms, Strength & Mining

- Solution name:

-

Timing belt

- Coloration:

-

Black

- Software:

-

Power Transmission Belt

- Size:

-

Regular Dimensions

- Attribute:

-

Minimal Noisy

- Good quality:

-

Substantial Degree

- Packing:

-

Cartons

- Pitch:

-

four.5mm

- Gain:

-

Substantial efficiency

- Teeth:

-

forty-201

Offer Ability

- Offer Ability:

- 5000 Piece/Parts per Month

Packaging & Shipping and delivery

- Packaging Details

- Carton box+ wood scenario

- Port

- Tianjin/Shanghai/Ningbo

-

Direct Time

: -

Amount(Baggage) 1 – one hundred a hundred and one – 500 >500 Est. Time(days) 15 thirty To be negotiated

On the internet Customization

EPG provide widest range of gearbox and speed reducers, conveyor chains and transmission areas like equipment, sprocket, racks, pulley, shaves and taper bushes etc for a variety of programs

Solution Description

|

Product identify |

Timing belt |

||||||

|

Material |

Rubber,PU, steel wire |

||||||

|

Sort |

Open,round |

||||||

|

Model dimensions |

T variety:MXL,XL,L,H,XH,T2.five,T5,T10,T20,AT5,AT10,AT20 |

||||||

|

Arc type:2M,3M,5M,8M,14M,20M,S2M,S3M,forty four.5M,S5M,S8MS14M |

|||||||

|

Colour |

Black,white,green,ect |

||||||

|

unique location |

China |

||||||

|

Advantage |

Large energy, anti oil, heat, ageing,Excellent bending resistant performance |

||||||

|

Software |

belt extensively utilized in machine resources, textile, printing, foods packaging, wire and cable, instruments and meters, petroleum chemical, |

||||||

Distinct sort timing belt

ARC variety

T kind

Open type

Spherical kind

Software

Catalog

Payment

Our Firm

HangZhou EPG – The greatest transmission areas manufacuturer in China Electrical Products Co.,Ltd was started in HangZhou in 2008 and is a skilled manufacturer and exporter that is anxious with the design and style, growth and manufacturing.With comprehensive requirments, we can also create your unique created product. Our merchandise assortment includes all types of Timing pulley,helical gear, spur equipment, bevel equipment, equipment rack, worm equipment, sprockets,Bike sprockets and chains

· Our Basic principle: “Reliability Supremacy, and Buyer Very first”

· Our Guarantee: “High quality merchandise, and Exceptional Provider”

· Our Price: “Being Honesty, Undertaking the Best, and Lengthy-long lasting Improvement”

· Our Intention: “Create to be a chief in the electrical power transmission areas sector in the planet”

EPG – The largest transmission components manufacuturer in China Main Products

Industrial Sprocket

Motorcycle Sprocket

Roller Chain

Spur Equipment

Helical Gear

Bevel Equipment

Plastic/POM/Nylon Equipment

Small Pinion Gear

Worm Gear and shaft

Gear Rack

Timing Pulley

Taper Bushing

Chain Guides

Linear Rail and Block

Ball Screw

China best quality low sales price for china manufacturer factor direct sale farm machine parts Cotton Picker Nut with Bushings Factory Manufacturer and Supplier -from Pto-shaft.com

It is our purpose to offer a large assortment of good quality products at cost-effective rates, give the very best provider for clients content and contribute to our ongoing improvement.

Overview

Rapid Details

- Guarantee:

-

1.5 a long time

- Relevant Industries:

-

farms

- Following Guarantee Service:

-

Video clip technological support

- Neighborhood Services Area:

-

canada. turkey

- Showroom Area:

-

Egypt

- Video clip outgoing-inspection:

-

Supplied

- EPT Te EPT Report:

-

Presented

- Advertising Variety:

-

EPT Merchandise 2020

- Warranty of main components:

-

one.5 years

- Main Elements:

-

Gearbox. Gear

- Key Offering Points:

-

prolonged services lifestyle

- Product Title:

-

Straight Bushing

- Application:

-

Harverster Device

- MOQ:

-

10

- Shipping and delivery time:

-

15

- substance:

-

stainless metal

- item No.:

-

SK112394

- warranty:

-

one.5 several years

- Brand:

-

Mianyou

- Area of origin:

-

china

EPT Capability

- EPT Ability:

- 200000 Piece/Pieces per Thirty day period

Packaging & Shipping and delivery

- Packaging Particulars

- factor immediate sale farming equipment components Cotton Picker Nut with Bushings

- Port

- Shanghai/Ninbo

-

Direct Time

: -

Quantity(Luggage) one – five hundred >500 Est. Time(times) fifteen To be negotiated

Online Customization

Product Description

| Description | Issue direct sale farming device elements Cotton Picker Nut with Bushings |

| Item No. | SK112394 |

| Material | stainless metal |

| Brand | Mianyou |

| Place of orgin | China |

Product Show

Relater Products

Organization Data

Logistics Shipping and delivery

one.Q:Are you maker or trade company?The place?

A:We are producer which located in HangZhou.ZheJiang China . EPG – 1 of the bigge EPT Agri- EPT components manufacturing facility in China .

two.Q:What is your phrases of payment ?

A: Payment=10000USD. 50% T/T in ept .harmony ahead of cargo. Irrepealable LC at sight for massive buy is considerable.

three.Q:What about delivery time?

A:The delivery time is dependent on item and amount .If you want to know the actual time. E-mail us the amount.we will check the time for you.

4.Q:Is the internet site cost the closing price tag?

A:No. All the prices are negotiable dependent on the quantities.

5.Q:How will you handle item good quality?

A:We strickly control every detail of manufacturing and every solution is inspected by our QC staff prior to shipping and delivery. In addition.our generation is abided by ISO 9001.

six.Q:When can you get the reply?

A:Any inquiries will be replied inside of 24 several hours.Our income staff will try our be EPT to support you.

EPG – As one particular of the most significant equipment transmission and agricultural component and gear manufacturing facility in China, we will provide your higher good quality items with most affordable cost. We update new products regular monthly from pto-shaft.com

Hot China sell sheet metal cnc machining parts service part of sewing machine – Supplier Manufacturer wholesaler Factory

For far more information.: Cellular/Whatpp: +8613083988828

After the PTO has started to electricity the attachment, steadily improve the throttle until you achieve the working velocity. The typical managing RPM (revolutions for each moment) for a tractor mounted PTO is 540 RPM, despite the fact that there are tractor designs that rev larger. Usually refer to your particular tractor product for instructions prior to 1st-time use.A formal quality assurance system with TS16949 certification insure that the completed products meet the consumers specifications. And we also have very prosperous international trade knowledge for many years. So we do think we can offer the ideal service to you. Our main goods are Needle Roller bearings, Cylindrical Roller Bearings, Rod end Bearings, Spherical simple bearings, Monitor roller Bearings for Guideway, Roller Bearings, Combine Bearings for forklifts, Water Pump Bearings, SNR Car Bearings and all types of Spherical Bearings. Our goods is popular exported to the United States, Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Center and South The usa, Thailand, Pakistan, Indonesia, a lot more than sixty nations around the world and locations.

Overview

Quick Specifics

- Applicable Industries:

-

Production Plant

- Manufacturer Name:

-

OEM

- OEM Services:

-

Support

- Tolerance:

-

.01-.05mm or Custom-made

- Certification:

-

ISO9001, SGS

- Area Treatment:

-

Sandblasting,Sprucing,Anodize, Zinc,Nickel,Chrome,Plating, and many others.

- Application:

-

Automobile,Healthcare Equipments,Electric powered Appliance,Components,and so forth.

- Dimension:

-

As Customers’ Ask for

- Gear:

-

Milling/Lathe/Drilling/Four/Three Axis CNC Machining Heart

- Drawing Format:

-

Professional/E, Car CAD, Reliable Works,IGS,UG, CAD/CAM/CAE

Source Potential

- Provide Capability:

- 10000 Piece/Items for every Month

Packaging & Delivery

- Port

- nb

-

Guide Time

: -

Quantity(Pieces) 1 – five hundred >500 Est. Time(times) 30 To be negotiated

On the web Customization

Sizzling market sheet metal cnc machining elements service element of stitching device

Merchandise Description

| Product Sort | CNC turning, milling, drilling, grinding, wire EDM cutting and so on. |

| Our Providers | CNC Machining,Plastic Injection,Stamping,Die Casting,Silicone And Rubber,Aluminum Extrusion,Mould Making,etc |

| Material | Aluminum,Brass,Stainless Metal,Copper,Plastic,Wooden,Silicone,Rubber,Or as for every the customers’ demands |

| Surface Remedy |

Anodizing,Sandblasting,Painting,Powder coating,Plating,Silk Printing,Brushing,Polishing,Laser Engraving |

| Dimension | As customers’ request |

| Service Task | To provide creation layout, manufacturing and complex services, mould development and processing, and many others |

| Drawing Structure: | PRO/E, Auto CAD, Solid Works,IGS,UG, CAD/CAM/CAE |

| Testing Equipment | Digital Peak Gauge, caliper, Coordinate measuring equipment, projection equipment, roughness tester, hardness tester and so on |

| Industry used | Machinery weighty obligation tools electronic system Vehicle spare areas optical telecommunication |

| Packing | Eco-pleasant pp bag / EPE Foam /Carton packing containers or wooden boxes As customer’s distinct demands |

| Trial sample time | 7-ten days soon after confirmation |

| Delivery time | 7-30 times after receive the pre-payments |

| Payment Phrases | T/T,Western Union,Paypal |

OEM Provider

OEM Areas

Surface area Remedy

Generation Approach

Why Us

EPG – a single of the most significant transmission manufacturing unit in China, main items: worm geared motors, agricultrual gearbox, planetary equipment travel, helical,screw, beve gears and spare areas and agricultural parts manunfacuter in China /For much more data.: Cell/Whatpp: +8613083988828